Metal

Challenges

The role of the circular economy

General

General

- Increasing the added value of products as a means of differentiation versus industrial price reduction (metallurgy and metal products).

- Tailor-made value proposition and turnkey solutions.

- Collaboration in and between sectors.

Priority strategies and approaches

Priority strategies and approaches

- Waste recycling and landfill reduction.

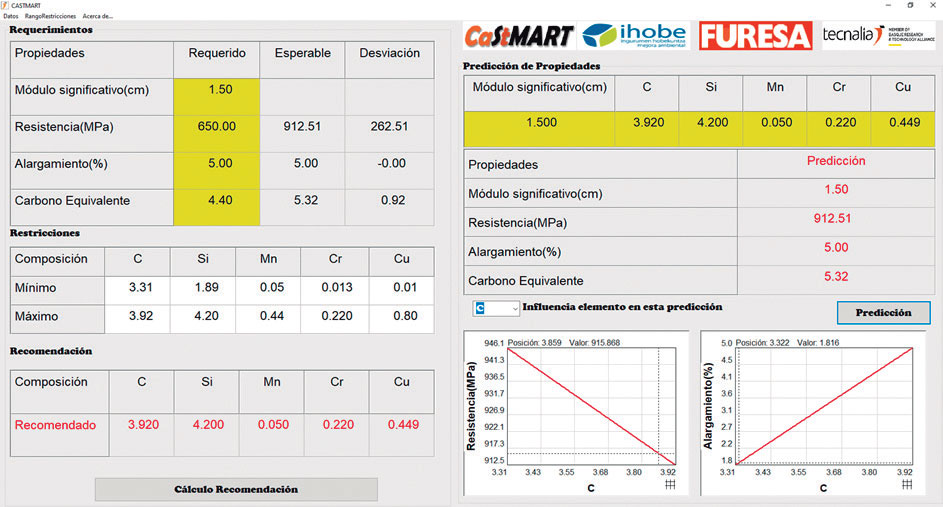

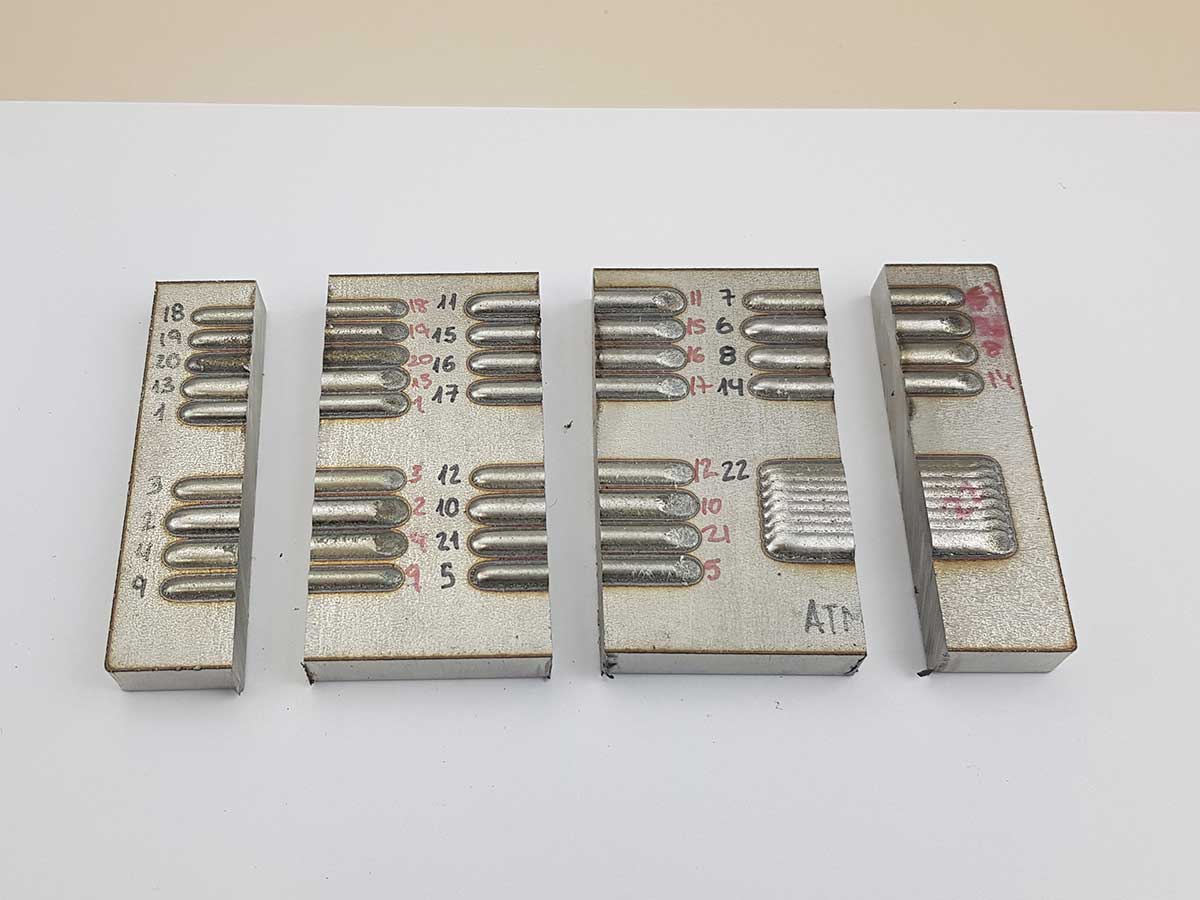

- Advanced materials (alloys).

- Best Available Techniques (BAT).

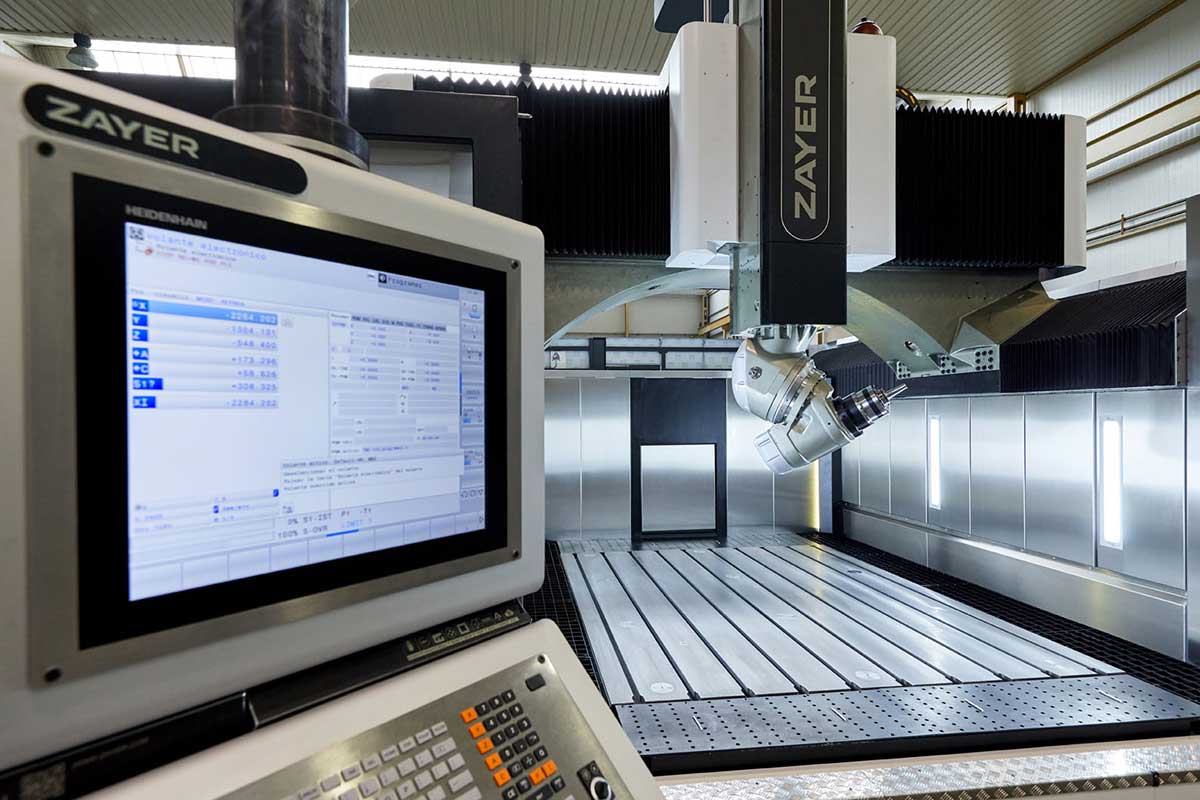

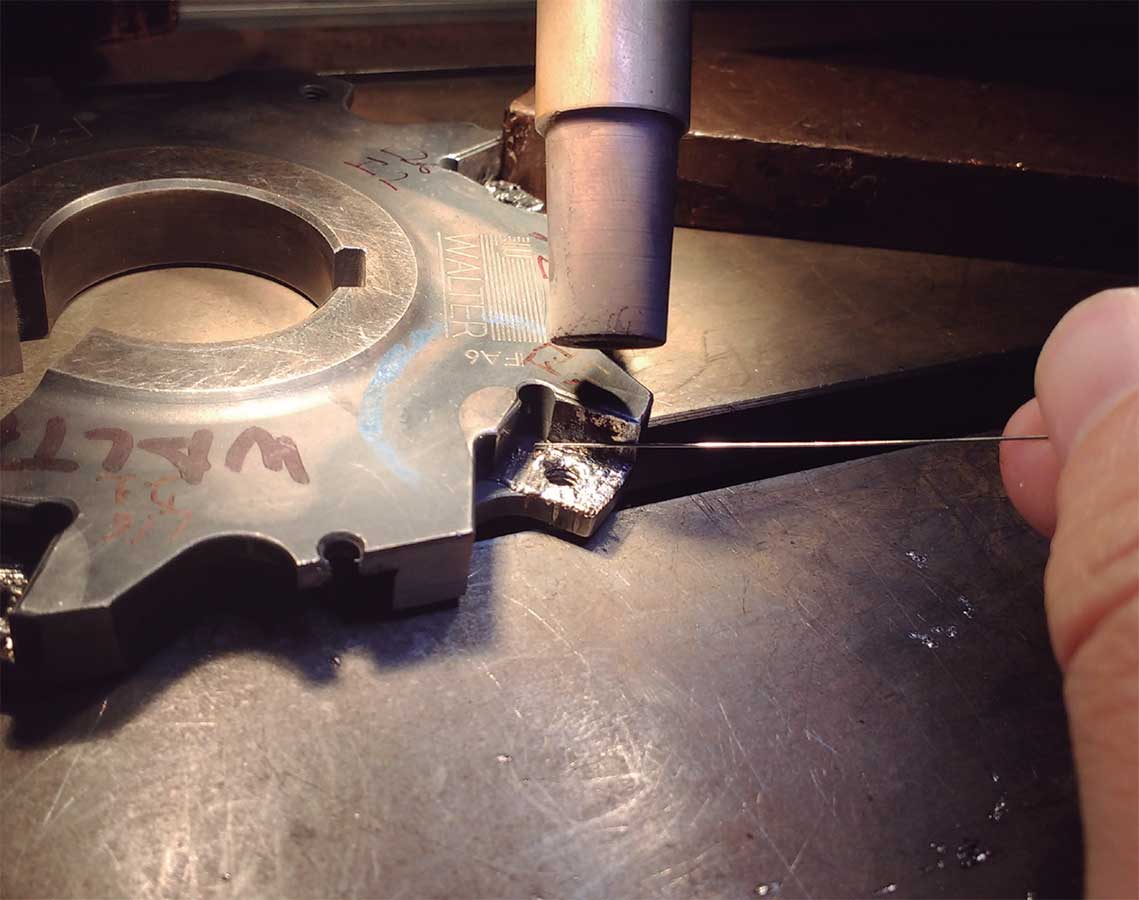

- Clean technologies (machining and forming systems and equipment, near net shape).

- Increased responsible consumption and corporate transparency.

Environmental

Environmental

- Reducing pollution, emission and disposal.

- Reducing dilution effect of key materials.

- Increase recycling rate.

- Reinforcing recovery and subsequent use of steel making slag from electric arc furnaces.

Competitive improvements

Competitive improvements

- Waste recovery (isostatic, salt slag, PVC waste stream, etc.).

- Re-introduction of waste from the steelworks and rolling mill areas into the production chain.

- Recycling waste to be used in other sectors (construction, etc.).

- Search for secondary material alternatives.

- Waste prevention and recycling criteria.

- Reducing industrial land contamination that promotes the dispersion of pollutants.

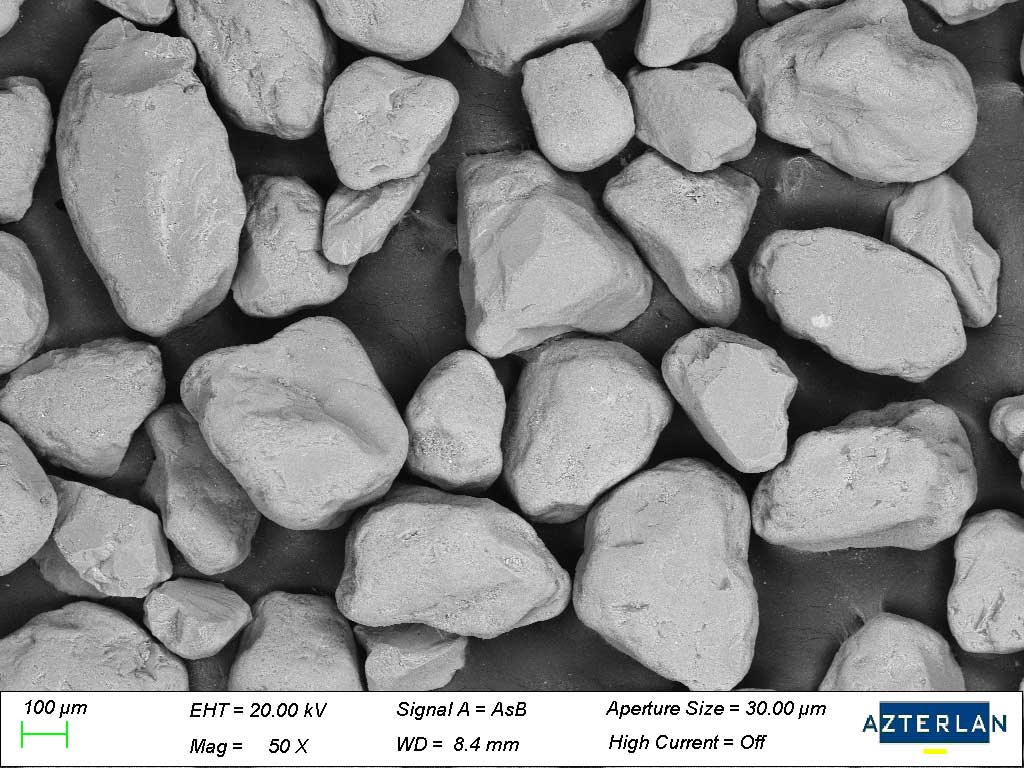

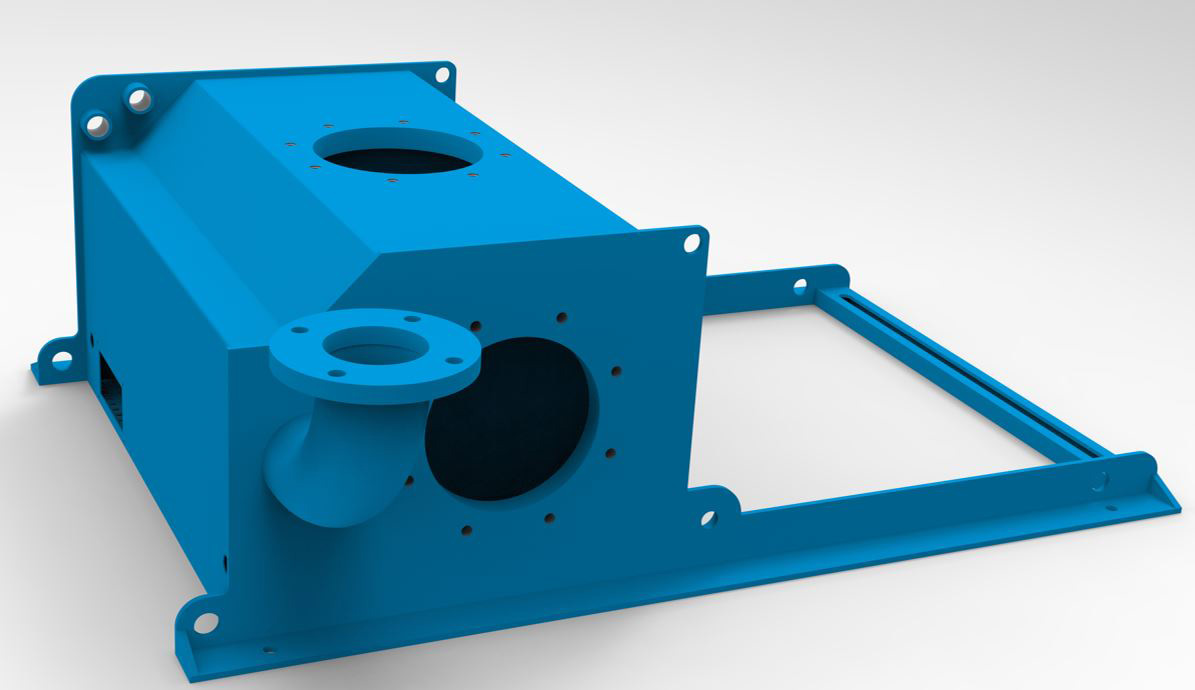

SECONDARY ALUMINIUM ALLOY FROM END-OF-LIFE VEHICLES FOR THE MANUFACTURE OF AUTOMOTIVE COMPONENTS

NEMAK