R2P2

REPAIRABILITY AND REDUCTION WITH PREDICTIVE AND PREVENTIVE SYSTEMS

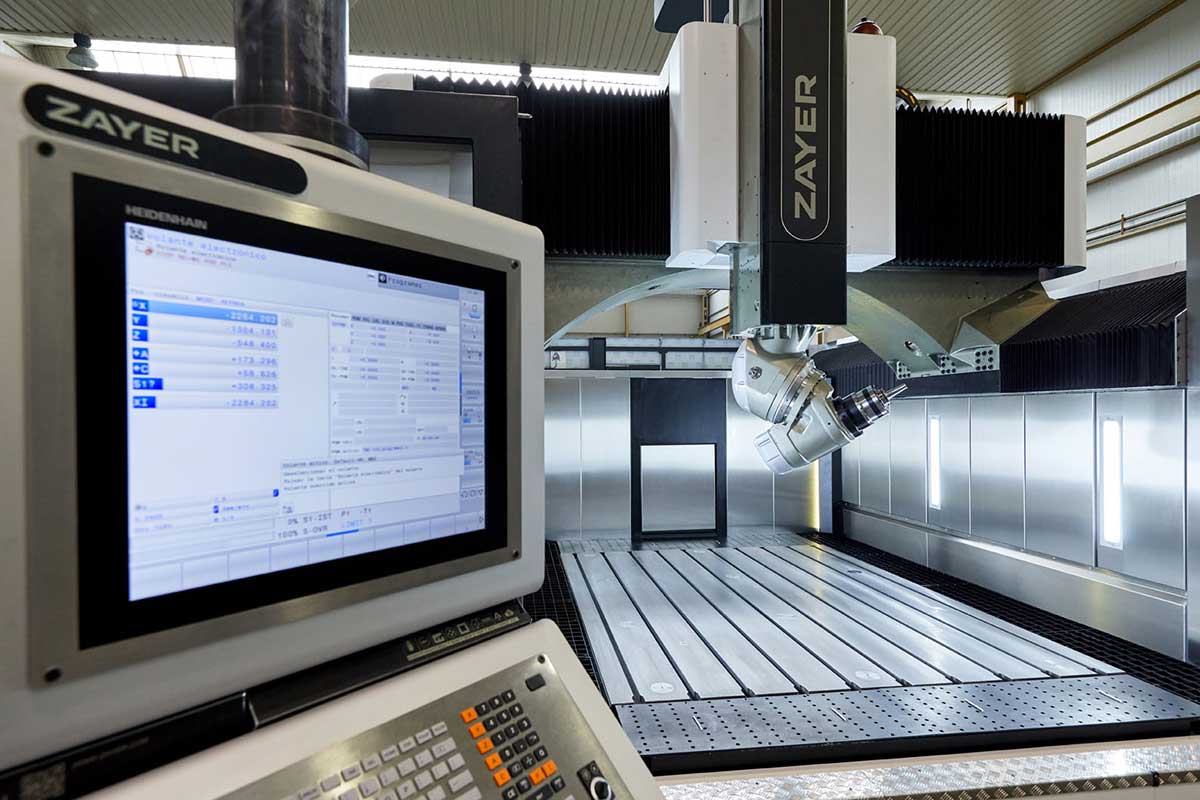

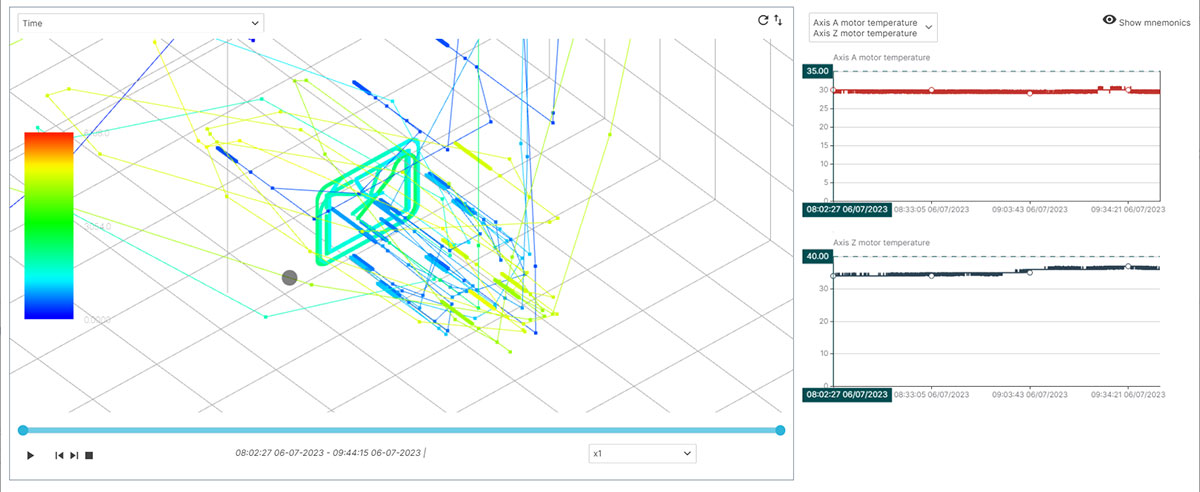

ZAYER currently has a 4.0 solution based on Cloud and Big Data technology for IIOT (Industrial Internet of Things) environments, as a result of different research and development projects carried out in the past. This solution, under the commercial name of "HORUS NX", enables the operational status of the machines to be controlled, the production of the machines to be monitored and the forensic analysis of the machining process and quality to be carried out. However, this platform depends fundamentally on a proactive attitude by the customer company, as it must carry out the analysis to draw conclusions and opportunities for improvement based on its particular machining processes, which allows for improvements in the tool's operability and efficiency. An opportunity has therefore been identified to improve the business model in order to reduce costs and environmental impact associated with the existing equipment maintenance system, through profound refocusing by implementing appropriate digital solutions.

ZAYER develops state-of-the-art milling machines and machining centres. To carry out R2P2, the company has worked with the industrial digitalisation expert, VIXION, and with GRUNVER SOSTENIBILIDAD, specialists in Life Cycle Analysis (LCA).

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Develop a new remote, automatic and decentralised diagnostic system for ZAYER equipment and implement a 4.0 predictive maintenance solution

- Reduce the number of repairs and replacements to be carried out by early identification of potential breakdowns in customer equipment, thereby reducing costs and environmental impact.

RESULTS

RESULTS

- Reduction of between 15% and 20% of the maintenance activities carried out by the ZAYER SAT team: travel of the technical department to the destination country for assistance, as well as the production and shipment of spare parts.

- Extend the service life of machines by 2 years until their first general maintenance overhaul (from 10 to 12 years).

- Estimated 6-year savings of 15 tonnes of CO2 equivalent emissions per year.

- Estimated 6-year increase of 5% in market share, with 4% of overall turnover dependent on R2P2 results.

CONCLUSIONS

CONCLUSIONS

- R2P2 has demonstrated that the proactive use of digital technologies enables environmental improvements to the product profile and makes the company competitive.

- Reducing the number of breakdowns not only brings value to the customer by increasing productivity and reducing maintenance costs, but also avoids a large number of human trips and the shipment of materials. On the other hand, it allows for the transformation of the traditional SAT model into a new hybrid model, where the active monitoring of the machines provides value that is tangibly perceived by the customer.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET