BANCASIL

SILENT BEDPLATES TO REDUCE THE SOUND PRESSURE OF BLOWING MACHINES

The European Union adoption of Directive 2002/49/EC of the European Parliament and of the Council of 25 June 2002 relating to the assessment and management of environmental noise has led to a new understanding of noise pollution, with special relevance being given to environmental noise, which shall mean unwanted or harmful outdoor sound created by human activities, including noise emitted from sites of industrial activity. This directive has been transposed into national law and, at the regional level, Decree 213/2012 regulates acoustic quality in relation to infrastructures that fall within its competence, among other aspects.

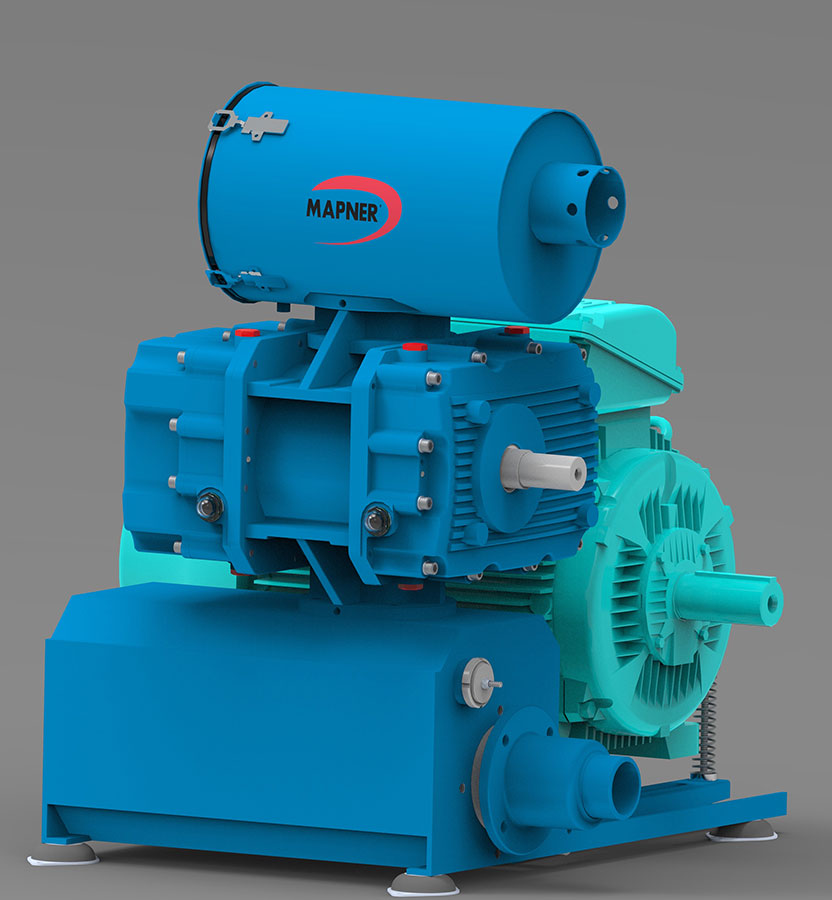

Maquinas Pneumaticas Rotativas XXI S.L.U. (MAPNER), the company behind the project, is a manufacturer of pneumatic rotary pumps with 85 years of experience. These machines provide solutions for various pressure and vacuum processes by means of different blower technologies and low pressure compressors. Blower technologies, however, generate noise in the workplace and present optimisable energy consumption.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Develop a technological solution to reduce the noise generated by the blowers manufactured at MAPNER, hence reducing noise pollution in the workplace.

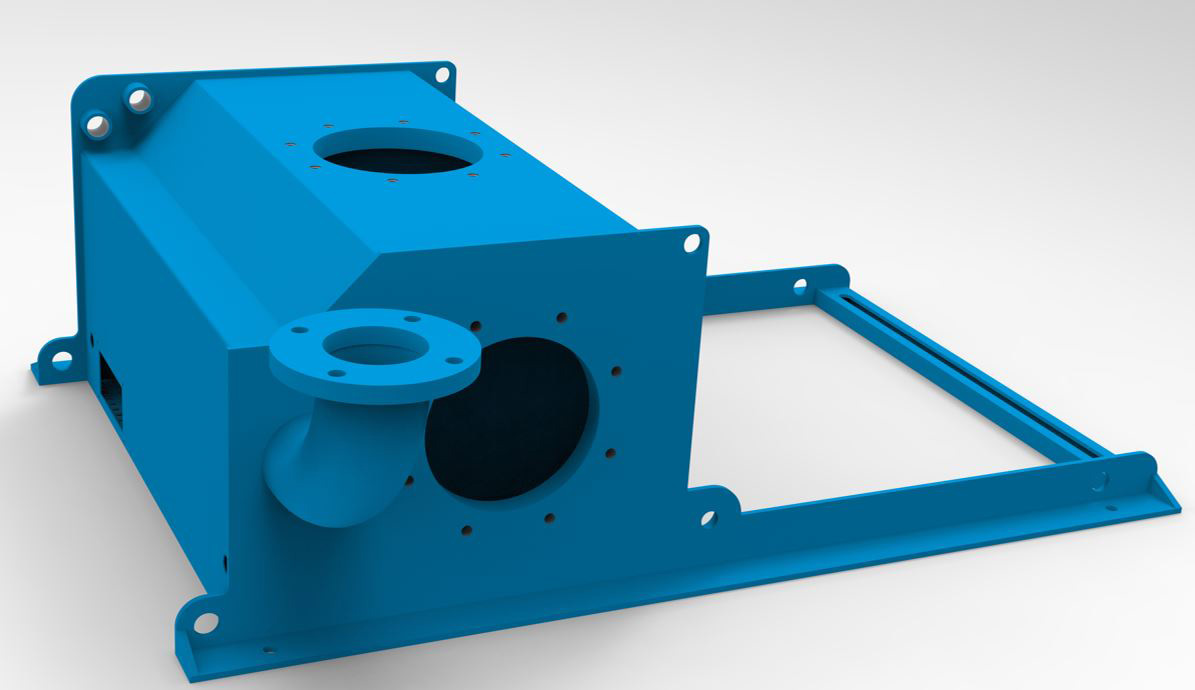

- Create a prototype of a silent 10 mm steel bedplate to demonstrate the noise reduction and increased energy efficiency of the blowers.

- Create a prototype of a silent bedplate with 8 mm of steel to compare the results with the silent bedplate of 10 mm and try to reduce the consumption of raw material while bearing in mind the parameters of noise reduction and increased energy efficiency of the blowers.

- Carry out development and demonstration pilots of the planned improvements on MAPNER test benches and at a customer's plant.

RESULTS

RESULTS

- Fully developed prototypes of the new 10 mm and 8 mm silent bedplates.

- Reduction of the noise pollution of the blowers with both bedplates, whereby the noise pollution is slightly higher with the 10 mm silent bedplate.

- Reduction of 1.45 kWh in the electricity consumption of the new bedplates compared to the old ones during use, due to the reduction of the pressure drop of the blowers.

- Saving of 9.27 tonnes of CO2 equivalent emissions per year for products with an average life of 30 years.

- Installation of the 8 mm silent bedplate at a customer’s plant, with highly satisfactory results in terms of noise reduction.

CONCLUSIONS

CONCLUSIONS

- Bedplates are currently made of cast iron. The use of steel instead of cast iron does not lead to an increased total environmental impact due to the offsetting of energy savings in the use phase of the blowers. Furthermore, the steel for the new bedplates is local (Hernani, Gipuzkoa). The use phase proves to be the key phase for reducing the environmental impact of MAPNER products.

- The reduction in noise pollution is similar for the 8 mm and 10 mm silent bedplates.

- MAPNER will manufacture and market the 8 mm bedplate as the most suitable for blowers, as they reduce noise pollution and increase energy efficiency in a similar way to 10 mm bedplates, but with lower consumption of raw materials.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET