AQUITANIA

REPAIRING CUTTING TOOLS USING NEW TECHNOLOGIES

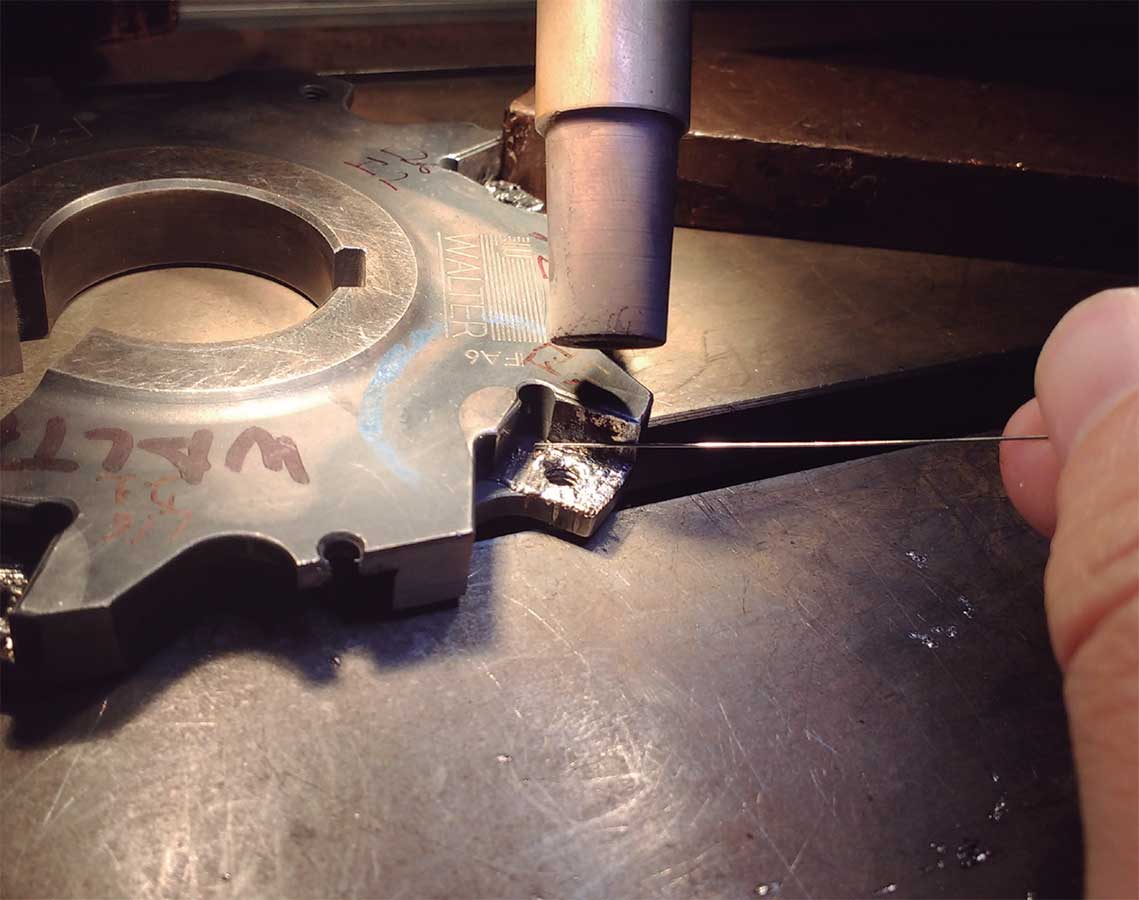

MANITEK’S MAIN ACTIVITY IS THE REPAIR OF REPLACEABLE TIP CUTTING TOOLS, which is normally carried out manually by means of TIG welding for the repair of cutting tools. Tools become damaged with use, blows, deformities or broken supports where the tip sits, and their recovery is an activity in demand due to economic and environmental criteria. The functionality of repaired tools is validated by experience, but there is a need to increase the level of automation in the process in order to reach a larger number of highly demanding customers.

MANITEK has led AQUITANIA, with the support of TECNALIA Technology Centre.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Demonstrate the application of new alternative technologies for the repair of cutting tools, such as: micro-laser deposition and LMD (laser metal deposition), additive manufacturing (AM) technologies.

- Increase productivity and productive capacity.

- Gain access to new customers and markets.

- Eliminate the environmental impact associated with manufacturing this type of tool.

RESULTS

RESULTS

- Accessibility study to assess tool positioning and potential constraints related to collision between the workhead and the workpiece to be repaired.

- Feasible micro-laser repairs, where three different tools requiring reduced surfacing volume are selected. A two-stage experiment was carried out to assess accessibility and different surfacing methods, as well as quality of welds.

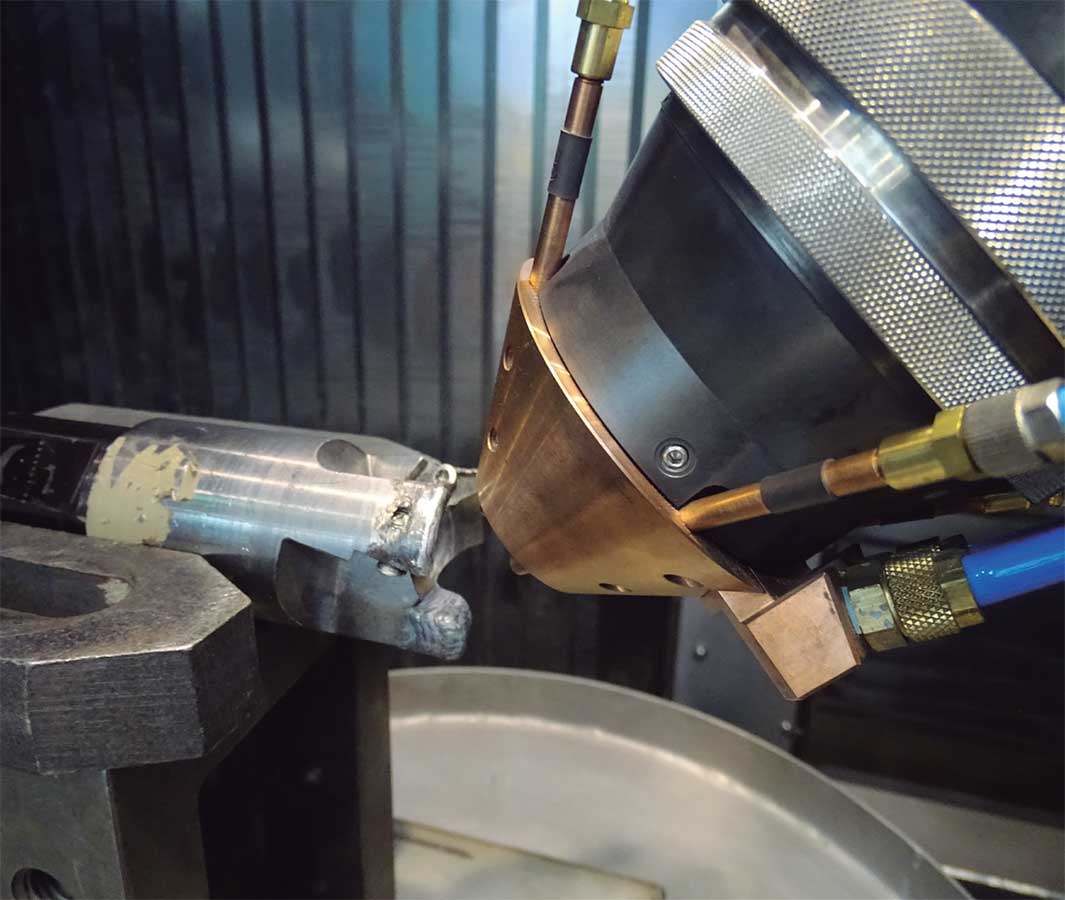

- Feasible repairs by LMD technology using two types of fi ller materials.

- The micro-laser process allows welding with reduced heat and higher precision, which facilitates learning the welding technique. However, correct process execution requires a lot of training for laser positioning and moving, and no signifi cant productivity increase was observed. For this reason, micro-laser technology has been discarded in favour of LMD.

CONCLUSIONS

CONCLUSIONS

- Cutting tools have complex geometries and difficult -to-access areas, therefore limitations posed by this factor need to be consider.

- AM technologies currently being developed are valid for implementation in SMEs, and have the potential of making a real impact on boosting the circular economy.

- In addition to technical feasibility, other critical aspects such as training for employees, raw material supply and equipment maintenance need to be assessed. Introducing this technology into the production process involves a significant economic investment.

- A more concise and applied study of LMD technology within MANITEK’s production activity is necessary.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET