AREZIKLA

REUSE OF FOUNDRY SANDS IN THE CORE-MANUFACTURING PROCESS

The problem of foundry waste sand in the Basque Country is one of the sector's priorities, as there are no sustainable or viable solutions for managing all the volumes of this waste stream. Around 154,000 tonnes of foundry sands and fines are generated annually in the Basque Country, and the recovery rate is around 35%. Landfill disposal is the predominant management method but estimates for 2030 show a significant shortfall in the capacity to accept such sand. Meanwhile, the new Basque Waste Plan has established a ban on landfill for green moulding sands in December 2023 and for chemical moulding sands in December 2025.

BETSAIDE is an iron foundry located in Elorrio (Bizkaia) with annual production in excess of 70,000 tonnes of liquid metal for which the management of foundry sand represents a major environmental challenge. AREZIKLA has been carried out in collaboration with the AZTERLAN Technology Centre.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Regenerate green sand waste for internal use in the crushing plant as a replacement for new sand.

- Carry out tests on prototypes that demonstrate the viability of green moulding sand regeneration systems, guaranteeing the requirements of the sand for use in BETSAIDE's core-manufacturing process, under the same production conditions and without varying the consumption of binding resins.

RESULTS

RESULTS

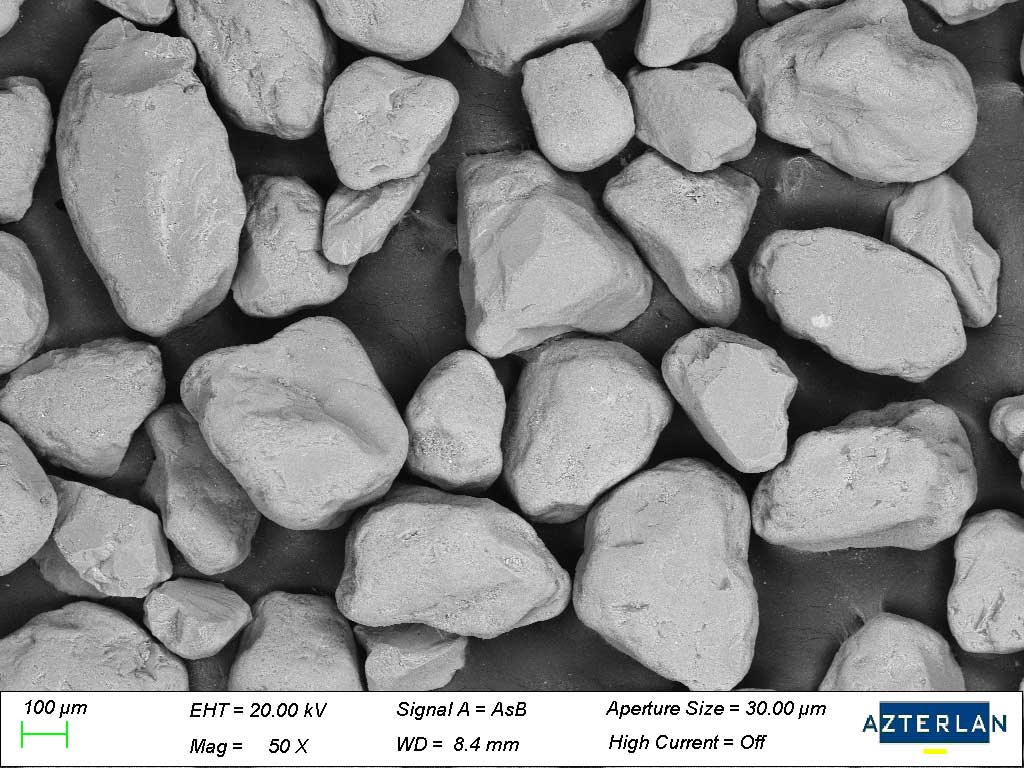

- Regeneration of foundry sand by means of a mechanical attrition process that achieves a high degree of sand cleanliness and suitable mechanical strength in core mixes based on 100% reclaimed sand.

- However, these characteristics are not enough for BETSAIDE core specifications and can be improved by adapting a reclaimed sand/new sand mixture.

- Reduction in CO2 emissions for scenarios using 100% or 60% reclaimed sand of 16% and 28%, respectively.

- Reduction in the fraction of PM2.5 particulate matter attributed to the use of reclaimed sand in both scenarios of 69% and 45%, respectively.

- The impact of the use of 100% reclaimed sand is slightly more than 60% as electricity consumption is higher in sand recovery.

CONCLUSIONS

CONCLUSIONS

- It is estimated that the BETSAIDE specifications can be achieved by designing mixtures of new and reclaimed sand and evaluating a mechanical-thermal process to improve the quality of the reclaimed sand and maximise the proportion of reclaimed sand in the mixture.

- The results of the project are of high value to continue advancing in the development of the green sand regeneration process and the adaptation of core manufacturing technology.

- Energy consumption and the waste fines generated may question the economic profitability of the solution.

- As a result of AREZIKLA, a new project, HAZITEK 2022, has been launched which seeks to progress in the mechanical and mechanical-thermal regeneration of green sand and the performance of validation tests on a pilot scale.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET