ECOPILA

Zn-AIR BATTERIES WITH REDUCED ENVIRONMENTAL IMPACT

ZN-AIR BATTERIES PROVIDE ONE OF THE HIGHEST ENERGY DENSITIES ON THE MARKET, while using active materials such as zinc (Zn) or manganese oxide, which are inert in the environment. Thus, reducing plastic in battery cells would result in an easily recyclable product with minimal environmental impact. On the other hand, batteries are subject to Extended Producer Responsibility (EPR), whereby the producer pays a fee when batteries are released to the market, for future collection and recycling. These collection processes are carried out by collective EPR Schemes, which are faced with: the geographical dispersion of batteries; a mix of batteries with different chemistries resulting in a low percentage of batteries being collected (barely 30% are collected and properly treated); and poor recycling of these batteries.

CEGASA focuses its activity on energy storage and is the world’s leading manufacturer of industrial alkaline Zn-air batteries, which have the highest energy density on the market. In ECOPILA, CEGASA worked with BOSTLAN as a partner company, which has a Zn waste management division.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Establish a new and complete circular economy route for Zn-Air batteries manufactured by CEGASA.

- Replace the polystyrene (PS) casing of batteries, due to recycling difficulties.

- Remove lead (Pb) content present in battery solder.

- Improve the efficiency of the collection systems and recovery of materials through the BOSTLAN recycling process, implementing a new line of business for the recycling of Zn-air batteries of European origin, in the Basque Country.

RESULTS

RESULTS

- Technically feasible replacement of PS envelope with cellulosic material together with a seal made of polylactic acid (PLA), a biocompostable material.

- Technically feasible process of welding with laser technology.

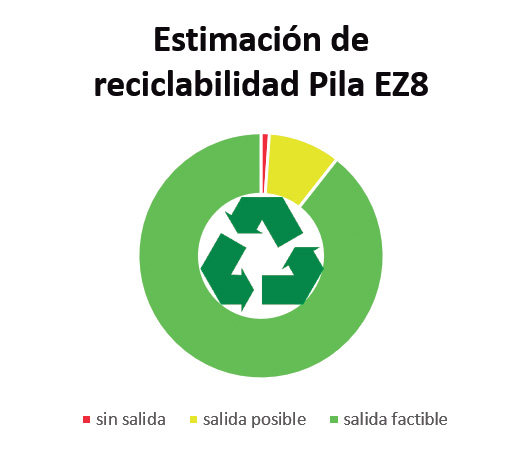

- Recovery of over 90% of the materials/components of post-consumer Zn-air batteries, improving by more than 40 points the minimum recycling rate required by the European Commission for this type of batteries. Zn recovery was similar to commercial types, and the process studied for the recovery of cathode materials also obtained good results and can be used again even at a higher level (manufacture of electrolytic manganese dioxide).

- Reduction of 2,770 tonnes of CO2 equivalent per year.

CONCLUSIONS

CONCLUSIONS

- Market research is needed to assess acceptance of a product with the same functionality as the current product but at a higher price. Depending on the results obtained, the necessary investments in equipment and adaptation of the production line will be decided.

- The recycling process proposed for ECOPILA - which also includes all types of Zn-air batteries - is technically and economically feasible, and therefore, Spanish and European collective ERP schemes are currently being approached to model the collection of spent batteries and to establish a pan-European network for the recycling of this type of batteries.

- • BOSTLAN has taken the fi rst steps to make the necessary investment in an innovative process for the recycling of Zn-air batteries in Europe.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET