SCOT

REDUCING ENERGY CONSUMPTION USING IMPROVED-PRECISION MACHINE TOOLS

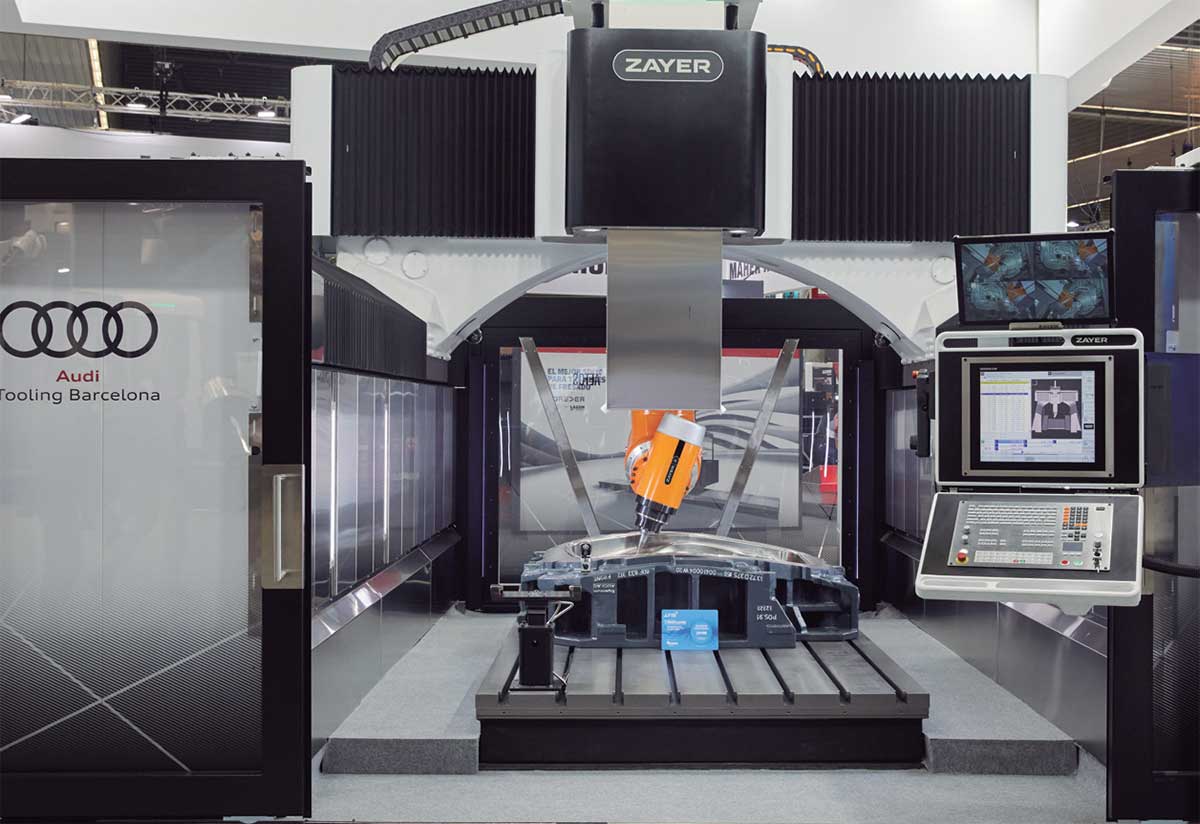

MACHINE TOOLS WORKING IN ENVIRONMENTS WITH HIGH TEMPERATURE VARIATION require high energy consumption due to the use of cooling systems. This consumption can be reduced by making the machines more tolerant to temperature changes, optimising the accuracy of machine operation. In turn, this signifi cantly reduces energy consumption at the production centre where the machine is installed, throughout its service life. ZAYER develops milling machines and machining centres with the highest quality and most advanced technology. For the implementation of SCOT project, the company collaborated with GRUNVER SOSTENIBILIDAD, specialists in LCA, and TEKNIKER technology centre, specialists in new precision technologies.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Reduce energy consumption of machines by 3%.

- Reduce by 30% the use of cooling systems, which produce high GHG emissions.

- Ensure 8μm accuracy and 5μm repeatability in non-cooled production environments.

RESULTS

RESULTS

- 35% reduction in the average use of machine cooling systems.

- Reduction of 2 to 5% in energy consumption of machines, depending on the model.

- 60% increased tolerance to room temperature changes, guaranteeing maximum machine precision.

CONCLUSIONS

CONCLUSIONS

- Although committing to use passive energy and lower environmental impact systems is more difficult from the start, the result gives rise to more value with less complexity, and customers welcome innovation in this direction.

- SCOT’s results demonstrate that environmental objectives can be a powerful catalyst driving new ways to improve products, generating new insights to guide the company’s innovation pathways.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET