ATOMCESS

REPAIR OF COMPONENTS BY ADDITIVE MANUFACTURING FROM POWDER STEEL

WINOA's current product is carbon steel shot between 100 µm and 2 mm. The production of special steel shot enables the use of applications with significant economic and environmental added value, working with granulometries similar to the nano scale. For this, it is necessary to use other technologies, such as atomisation by centrifugation (new in the Basque Country), in which WINOA also has a practical advantage due to its size and accessibility of installations.

Repair of defective parts from large castings by additive manufacturing could be beneficial for some 450 tonnes of special steels in high-value parts that are remelted annually in their manufacturing facilities due to minor non-repairable defects, with a consequent energy impact (consumption of 700 kWh per tonne). Although additive manufacturing may have great potential for the repair of these parts, it is still far from being applicable to mass production. However, in the case of ATOMCESS, the application is interesting as it involves the repair of extremely high-value units.

WINOA, world leader in the production of steel abrasives, is the promoter of ATOMCESS, with the participation of the CEIT Technology Centre, the circular economy consultancy firm, ZICLA, and the collaboration of the AMPO and TUBACEX steel companies.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Atomise new steel powders with the necessary characteristics to be used in the advanced repair of high value-added components using additive manufacturing techniques.

- Determine the optimum composition compatible for the manufacture of processable stainless steel powders by laser metal deposition (LMD).

- Design, build, implement and optimise centrifugal atomisation equipment (ATC) that enables stainless steel powder to be produced with sizes below 700 microns.

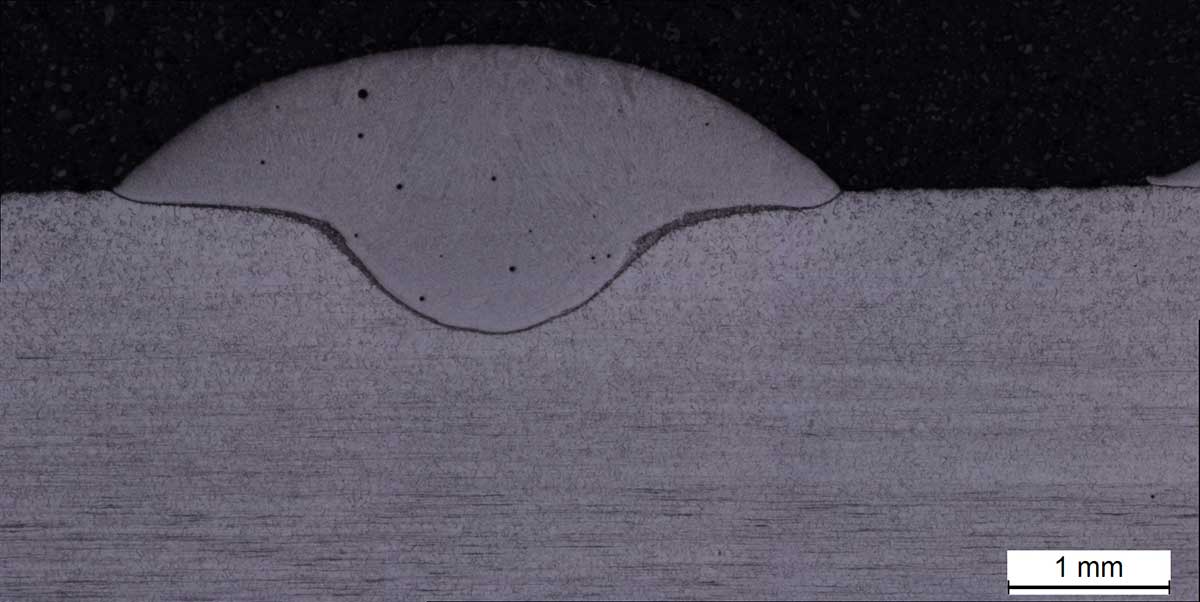

- Determine the conditions required by atomised powders for the repair of defects in flat demonstrators obtained from stainless steel parts supplied by AMPO and TUBACEX.

- Analyse the repaired materials and validate the process by means of the standardised tests applied to them.

RESULTS

RESULTS

- Determination of optimal compositional ranges compatible with the manufacture of stainless steel powders processable by LMD.

- Specific scrap selection with volumes available locally, adjustable content in composition and an affordable price.

- Design, installation and optimisation of the parameters of an ATC plant at the WINOA plant in Balmaseda (Bizkaia).

- Obtaining shot powder of a suitable composition, particle size and morphology for use in additive manufacturing.

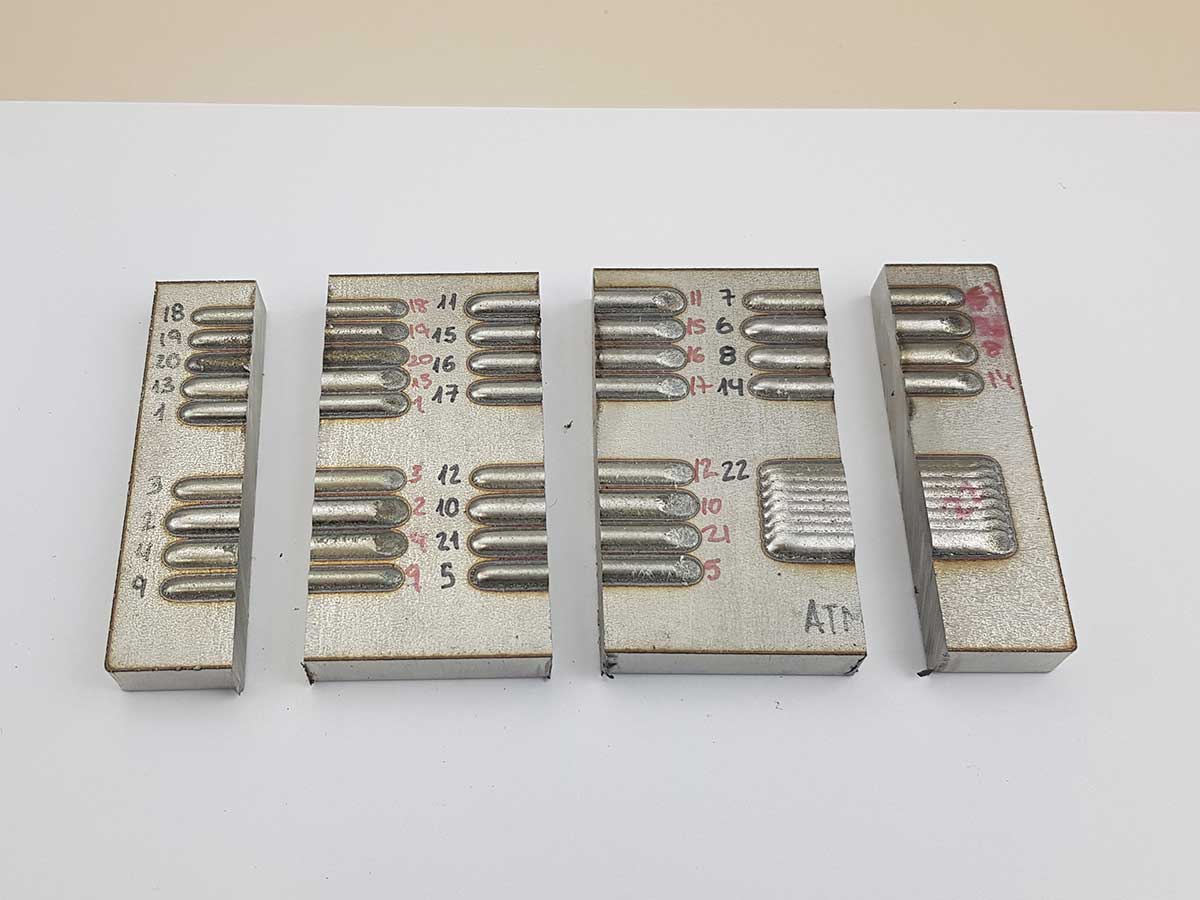

- Optimisation of repair parameters on stainless steel plate demonstrators including deposition rates.

- Generation and validation of specific process software for the stainless steel powder generated in the atomisation studies.

- Validation of ATOMCESS repair powder on cylindrical geometry for AMPO and TUBACEX materials and parts.

- Improvement of the environmental profile of the repair of steel parts by 99%. For each tonne of steel repaired, the emission of 523 kg of CO2, consumption of 281m3 equivalent of water, consumption of 7.35 GJ of energy or the emission of 1.38 kg equivalent of volatile organic compounds are avoided.

CONCLUSIONS

CONCLUSIONS

- Certain technical aspects of the installation require extreme precision in order to obtain the desired materials under the right industrial and commercial conditions. The optimisation of the parameters is therefore of high added value and has involved significant effort in the implementation of ATOMCESS.

- Although the process is considered validated, large potential customers of ATOMCESS need to repair parts with complex geometry and in areas that may be difficult to access, which involves developing prototype robots to complete the commercialisation of the project, as well as defining the final business model.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET