Best production techniques

The development of Best Available Techniques (BAT) for sectors with the highest environmental impact potential regularly results in additional emission limit requirements and, from now on, material and energy efficiency requirements for industrial processes. Fulfilling those requirements is a condition required to obtain and maintain an activity licence, called Integrated Environmental Authorisation

Metal

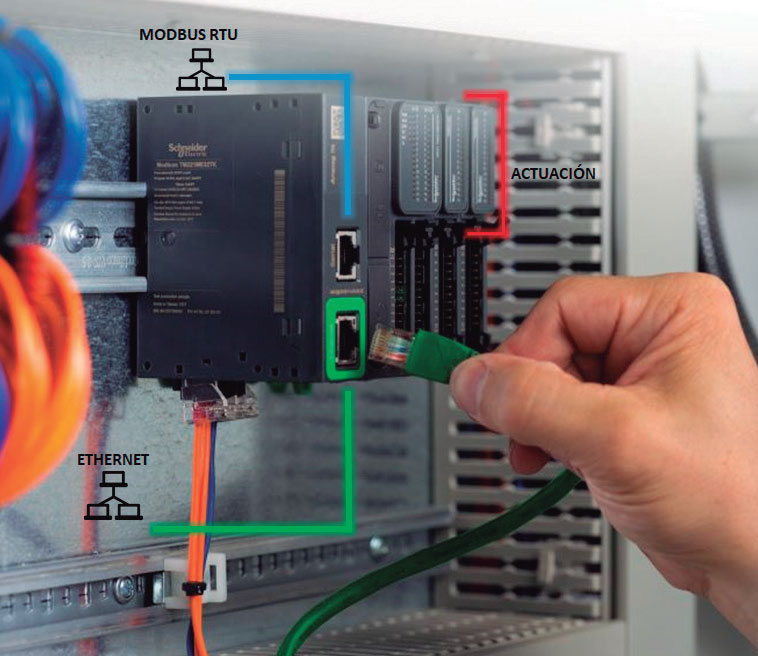

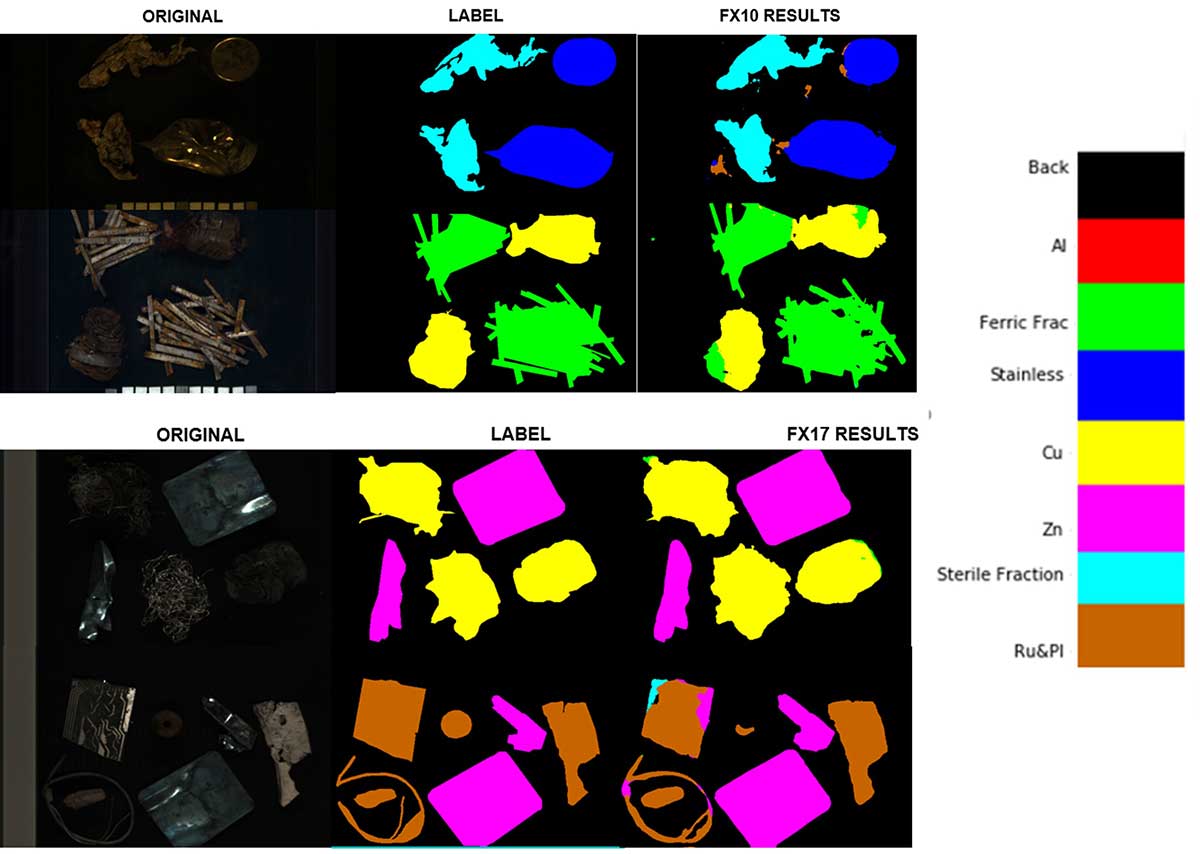

OPTIMISATION AND ROBOTISATION TO INCREASE THE QUALITY OF STEEL SCRAP

ARCELOR MITTAL

Chemical

OPTIMISATION OF THE PRODUCTION OF HIGH PURITY Zn COMPOUNDS FROM WASTE

BOSTLAN

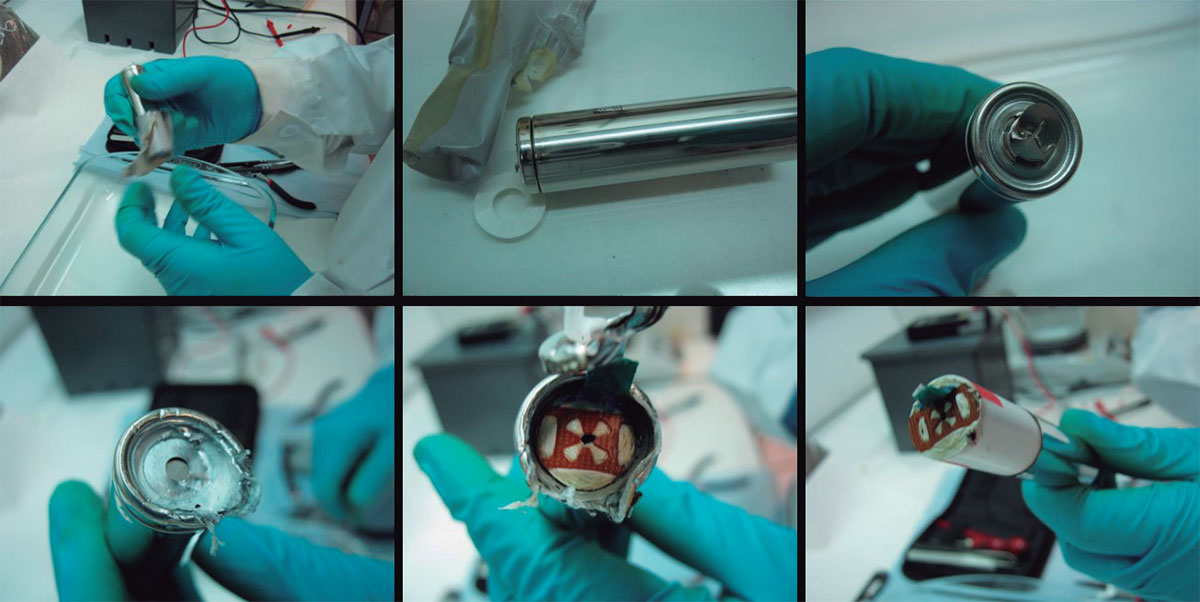

Electrical and electronic equipment

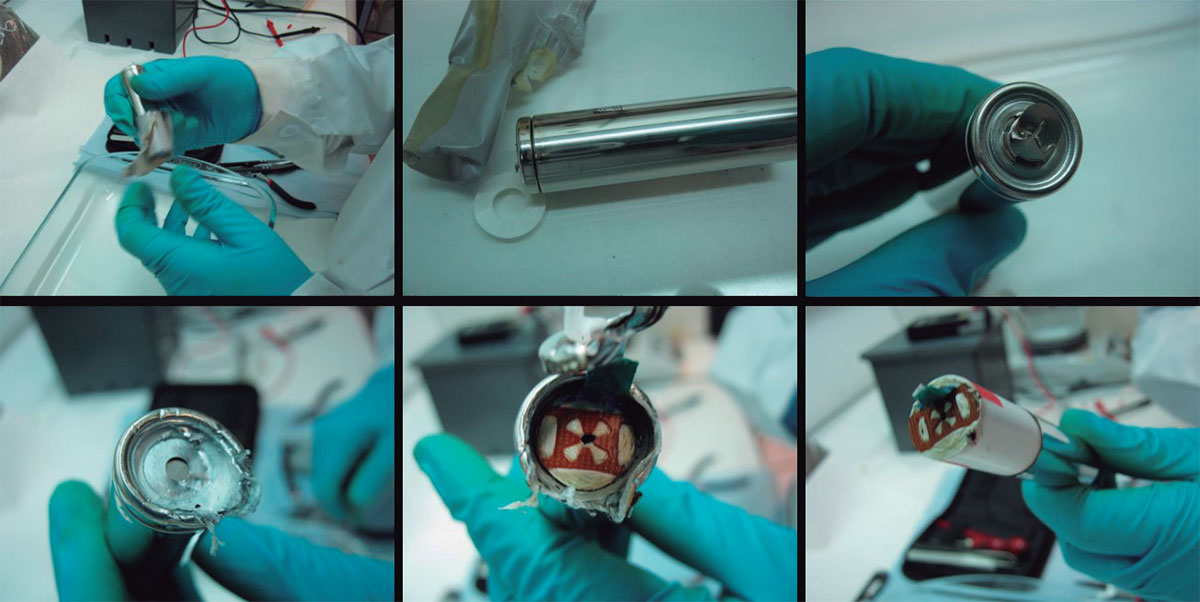

RECOVERING STRATEGIC METALS FROM LITHIUM-ION BATTERIES

REYDESA

Other means of transport

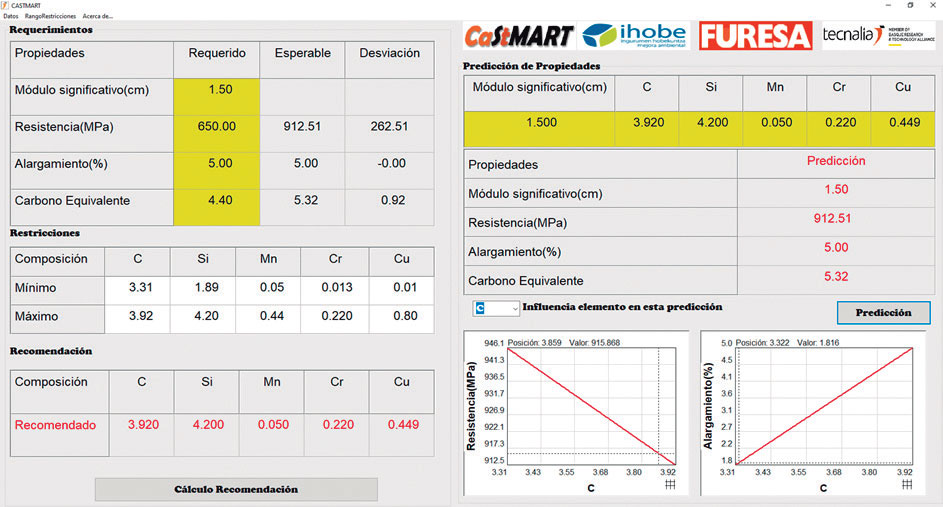

REDUCING THE ENVIRONMENTAL IMPACT OF RAILWAY COMPONENTS

FURESA

Metal

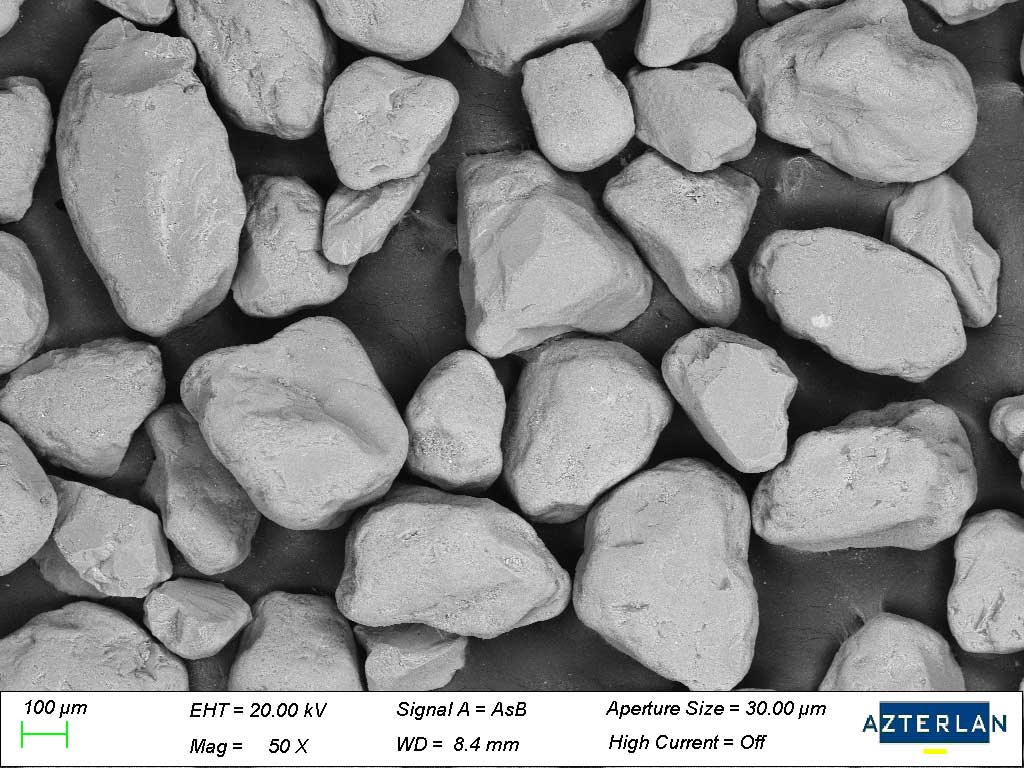

REPAIR OF COMPONENTS BY ADDITIVE MANUFACTURING FROM POWDER STEEL

WINOA

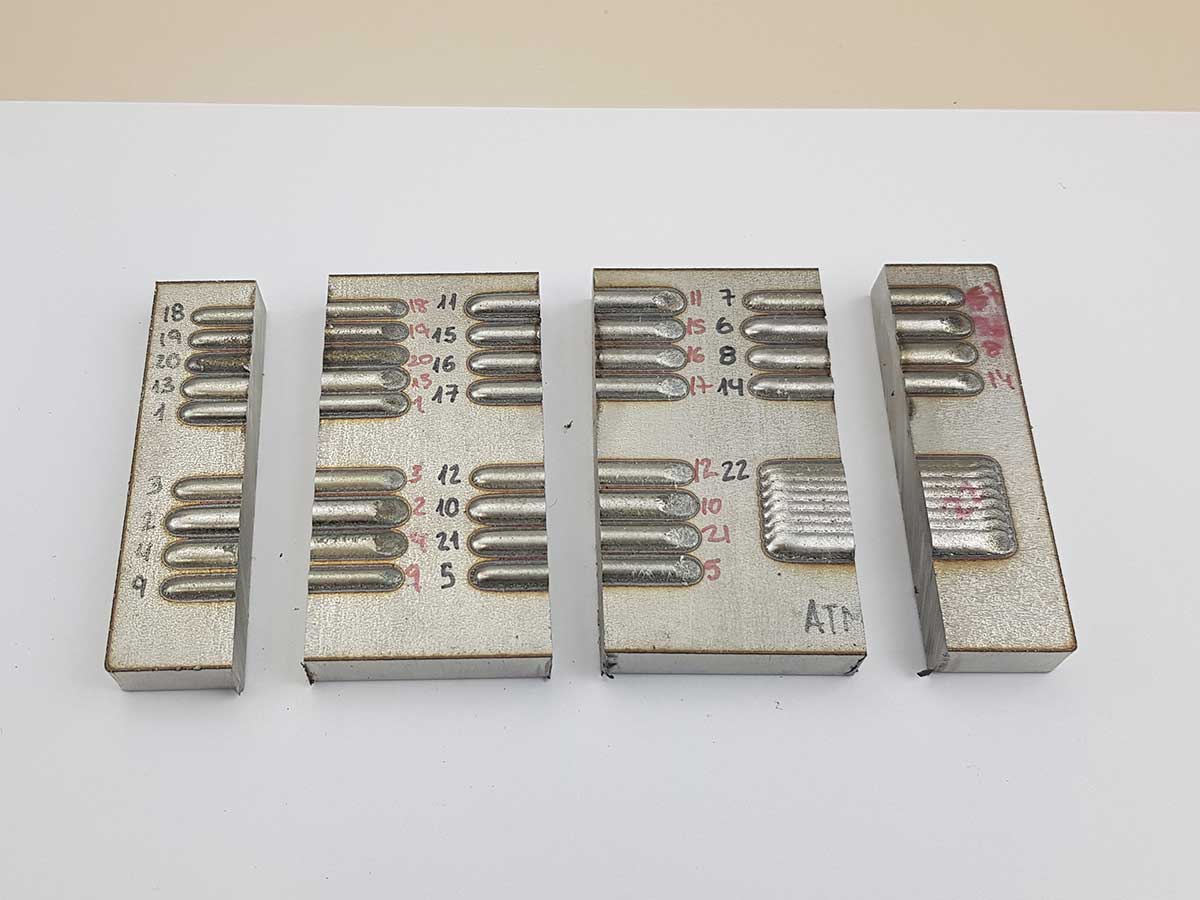

Metal

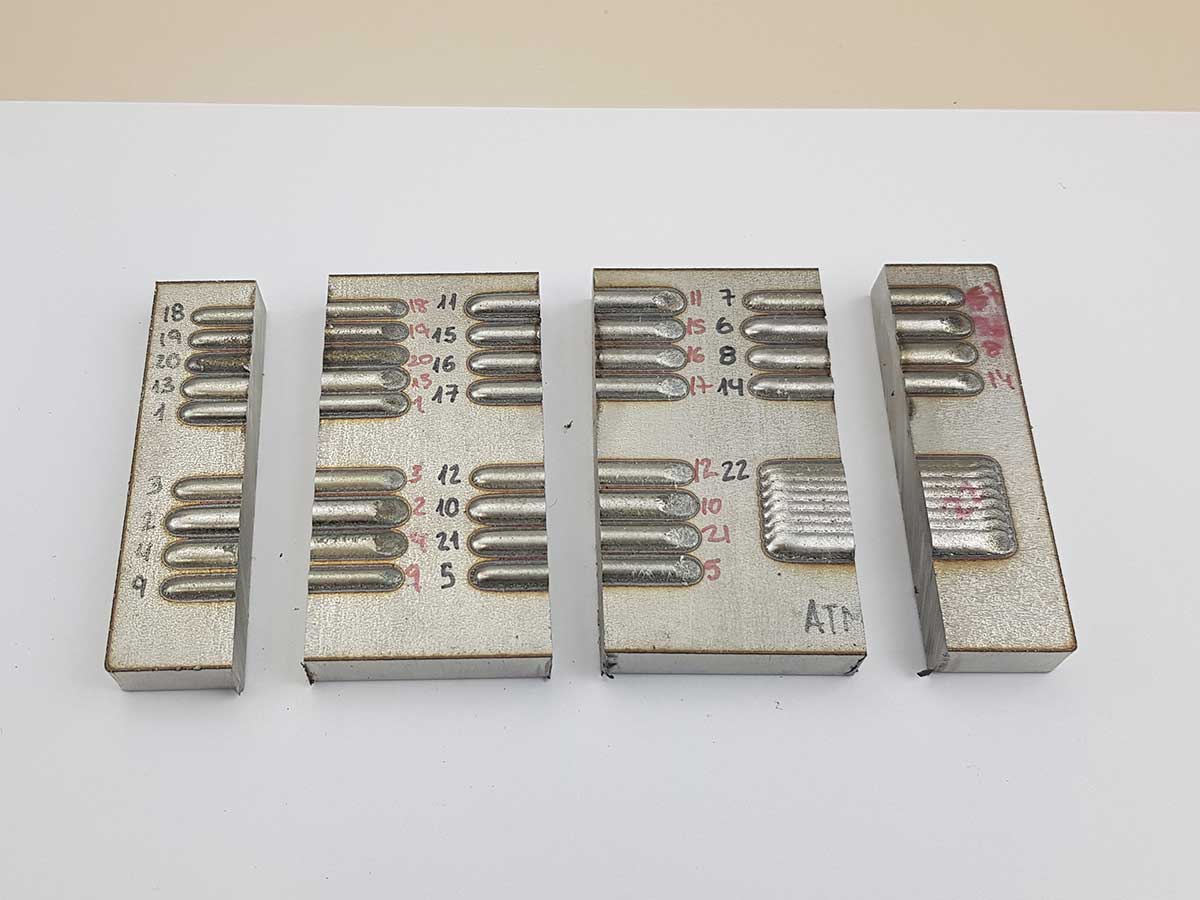

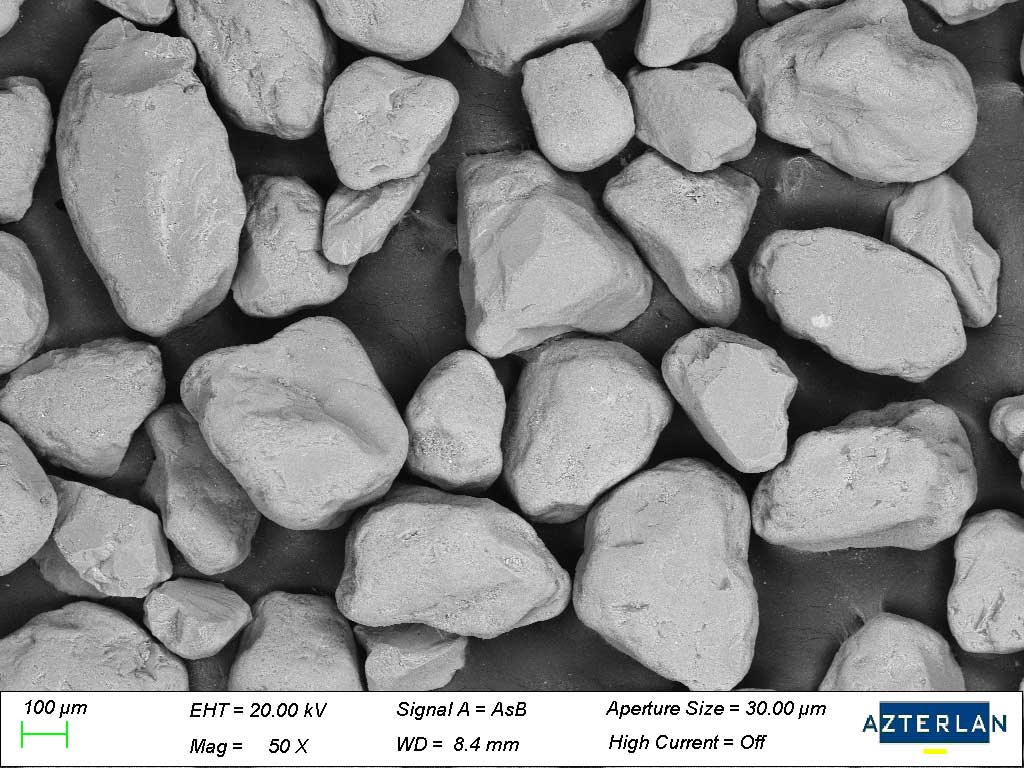

REUSE OF FOUNDRY SANDS IN THE CORE-MANUFACTURING PROCESS

BETSAIDE

Metal

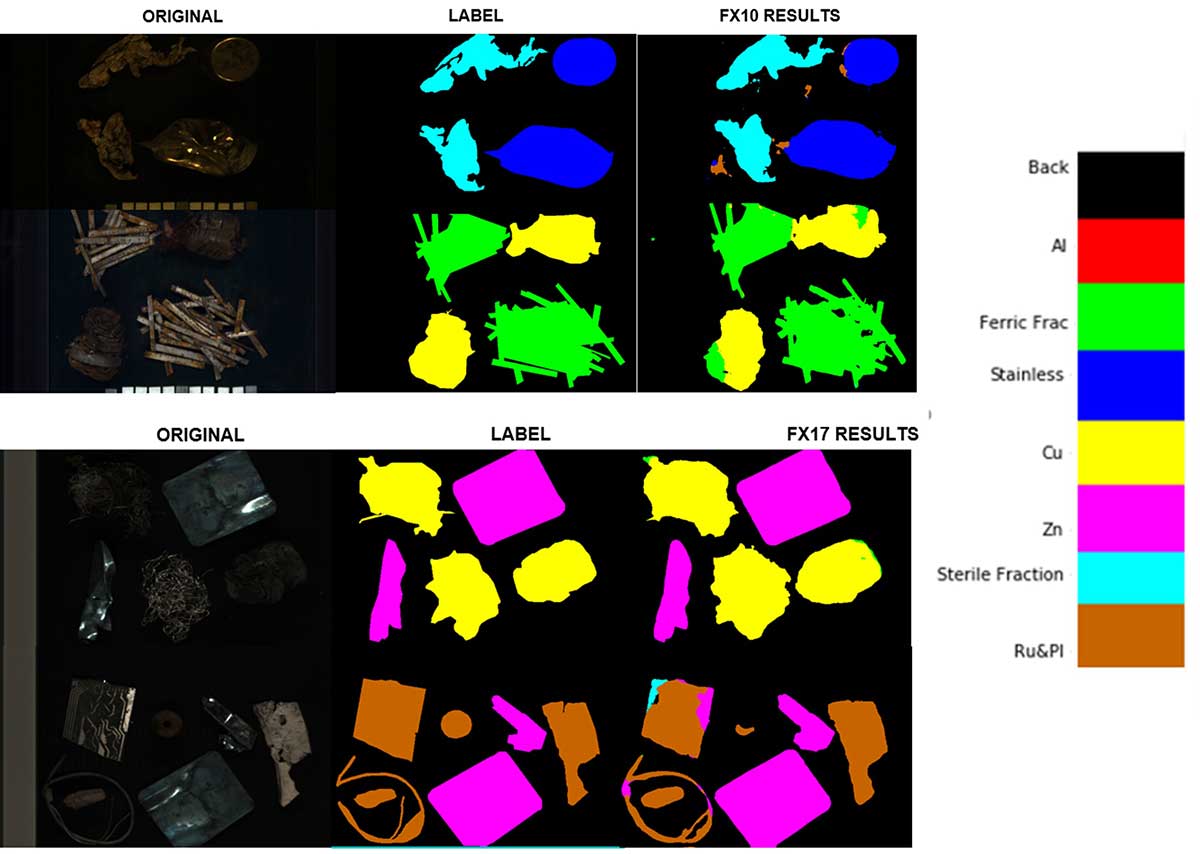

SEGREGATION OF SECONDARY ALUMINIUM ALLOY STREAMS

REYDESA

Metal

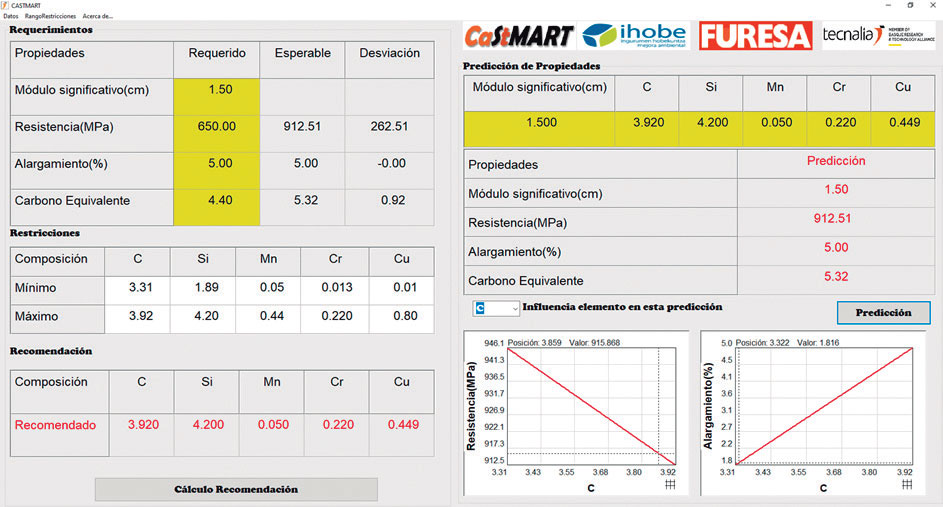

SELECTED SCRAP FOR THE MANUFACTURE OF NODULAR CAST IRON PARTS

FURESA

Machinery

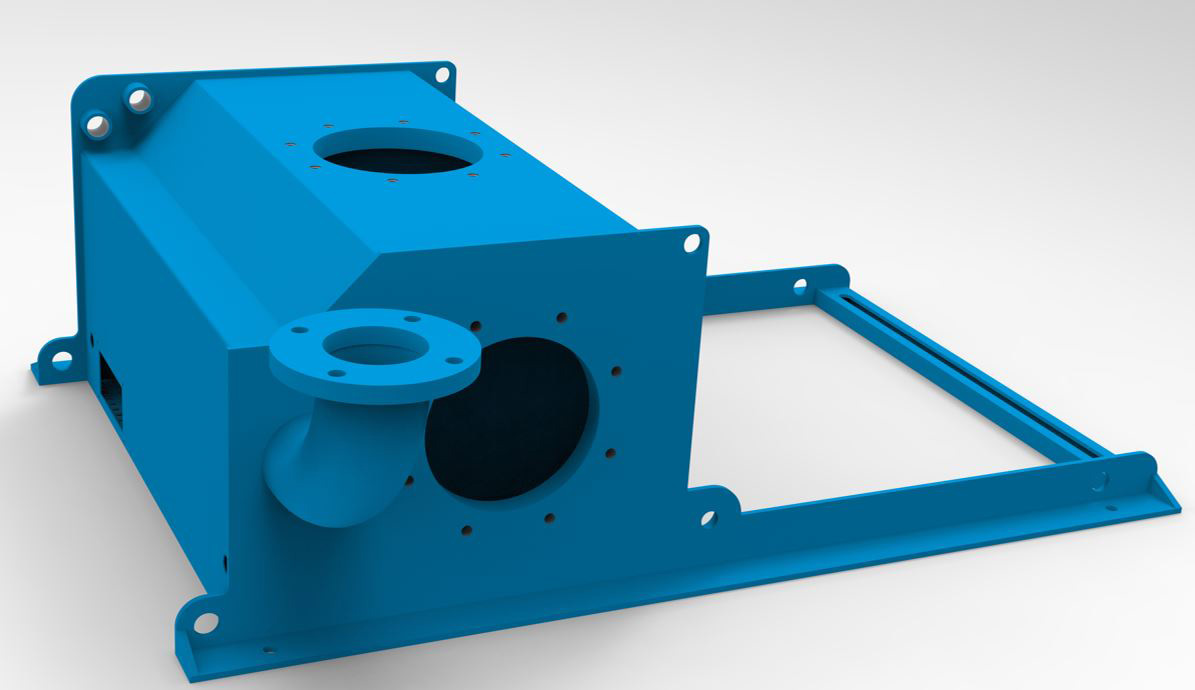

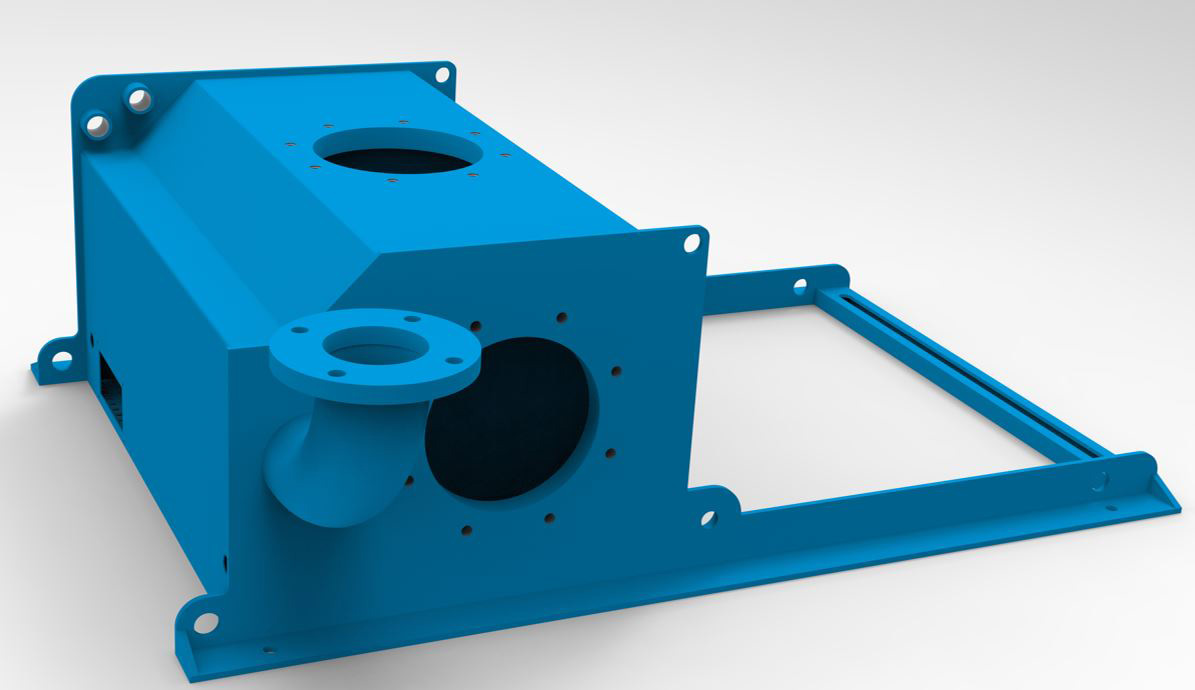

SILENT BEDPLATES TO REDUCE THE SOUND PRESSURE OF BLOWING MACHINES

MAPNER

Machinery

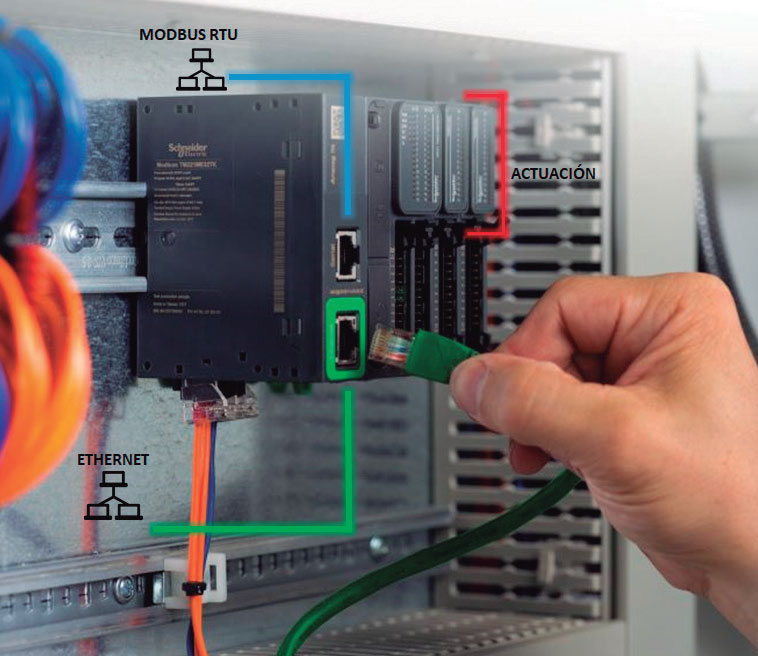

SMART DETECTION AND REMOVAL OF PARTICULATE MATTER EMISSIONS FROM INDUSTRIAL SOURCES

TEKNIMAP

Metal

SYSTEMATIC AND INTEGRATED RECOVERY OF REFRACTORY WASTE USING THE "5R" ENVIRONMENTAL MODEL

SIDENOR

Metal

USE OF CARBON-NEUTRAL MATERIALS IN THE ELECTRIC ARC FURNACE

SIDENOR