ALTXOR

OPTIMISATION AND ROBOTISATION TO INCREASE THE QUALITY OF STEEL SCRAP

The increase in scrap consumption and its low availability means that tools must be available to improve and control the quality of lower quality scrap for steel production. Steel scrap contains a series of residual elements that are harmful to steel, such as copper (Cu), tin (Sn), chromium (Cr), nickel (Ni), etc., which cannot be removed in the manufacturing process and must be diluted to guarantee the final quality of the steel to be produced.

ARCELOR MITTAL BASQUE COUNTRY RESEARCH CENTRE is a Research Centre specialised in the steel sector, which is currently working on optimising the electric arc furnace (EAF) process, continuous casting and the treatment of scrap through new characterisation technologies. ARCELOR MITTAL (AM) SESTAO manufactures high quality flat steel products from recycled scrap in an electric arc furnace, and is aiming to consume 100% local scrap, so the installation of a scrap treatment plant could be of interest to improve the plant's operating results.

ARCELOR MITTAL leads ALTXOR and has relied on the TEKNIKER Technology Centre and its experience in the development of artificial vision solutions.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Provide ARCELOR MITTAL plants with advanced tools for the characterisation of ferrous scrap, enabling them to optimise purchasing strategies for obsolete scrap as the main raw material.

- Drive the AM Sestao plant in its pilot decarbonisation process.

- Increase knowledge of existing technologies, capabilities and limitations of industrial scrap cleaning processes.

- Analyse in detail the distribution of materials that make up waste from cleaning processes and assess their recovery potential and environmental impact of the recovery processes.

- Develop new technologies for automatic sorting of materials in processed scrap streams under industrial conditions.

- Reduce energy consumption and consumption of ferroalloys and fluxes.

RESULTS

RESULTS

- Improve and control the quality of scrap using the magnetic separator for the separation of fragmented scrap, with a decrease in non-ferrous and non-metallic materials (Cu reduction by 0.20% and increase in Fe content).

- 10% reduction in environmental impact in all impact categories assessed by a comparative Life Cycle Analysis (LCA) with and without scrap sorting.

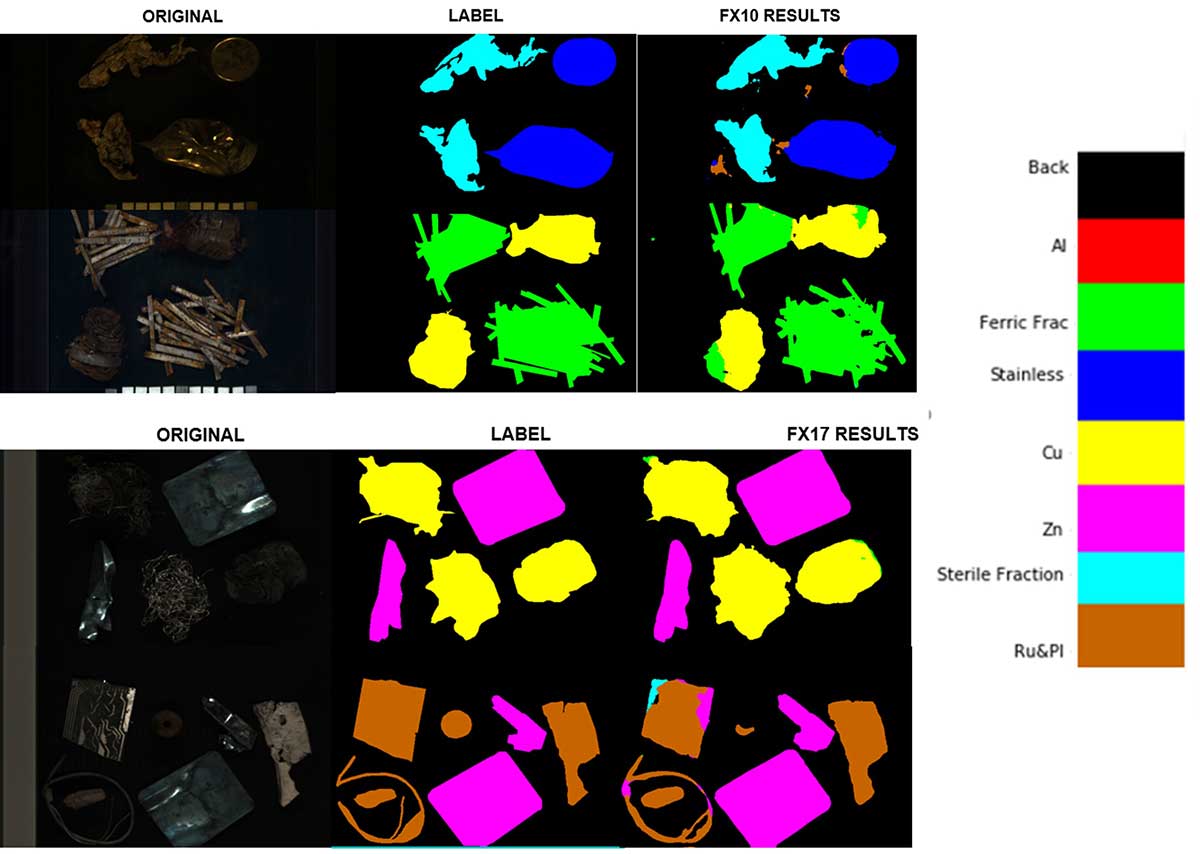

- Development and optimisation of a pilot sorting facility for ferrous materials capable of detecting the percentage of Cu, Ni, Zn, Al and sterile materials in pixel format in captures by hyperspectral cameras.

- Proposal for a continuous processing scheme with a bin-picking system for the recovery of non-metallic ferrous waste.

- Proposal for a model to measure the efficiency of cleaning machines (ferrous fraction measurement) for real-time optimisation of parameters.

CONCLUSIONS

CONCLUSIONS

- The technical, economic and environmental potential of scrap cleaning techniques is high. Given the results obtained, new lines of work have been opened up in terms of improving the quality of ferrous scrap. A new module is being designed for scrap preparation and adaptation.

- The development of a pilot sorting plant for ferrous materials enables harmful materials to be detected, which improves the iron and steel process and also enables the material separated by this sorting plant to be recovered, reducing its environmental impact on electric arc furnace processing, reducing fluxes and the waste generated (slag and emissions).

- The development of a sensor to measure the efficiency of cleaning machines is applicable to the outflows of a magnetic separator.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET