REMACOMPIND

REMANUFACTURING INDUSTRIAL PRODUCTS AND COMPONENTS

REMANUFACTURING IS A CIRCULAR ECONOMY STRATEGY BASED ON EXTENDING THE LIFE OF PRODUCTS and/or components at the end of their useful life. The industrial process involved consists of restoring a used product or component to a level of performance, quality and warranty equal or superior to that of a new product. In order to know if a product is suitable for Remanufacturing, it is necessary to study its typology, applicable Remanufacturing technologies and business model. Remanufacturing implies a resource-efficient manufacturing industry and its industrial development is strategic in AM development in the Basque Country, as well as representing a great opportunity for Basque industrial companies.

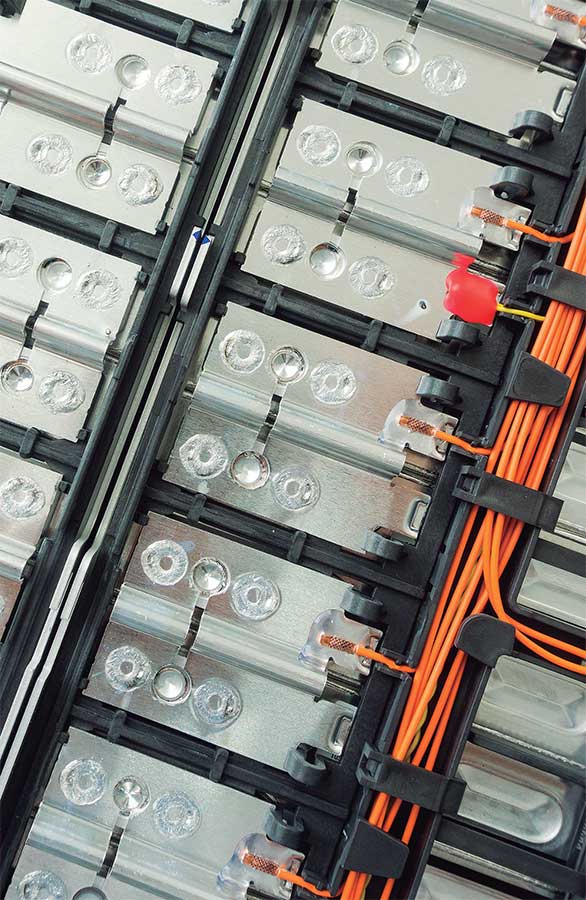

The ESCUELA POLITÉCNICA SUPERIOR de MONDRAGON UNIBERTSITATEA (EPS-MU) is leading REMACOMPIND, in which CEGASA, the manufacturer of industrial batteries, Lithium-Ion batteries and energy storage solutions, and the UNIVERSITY OF BAYREUTH have participated.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Identify and define Remanufacturing possibilities and R&D and Innovation in the Basque Country including: market niches for the Remanufacturing of industrial components, products and equipment in a planned, fast and economic way, and in compliance with the regulations in force in the major industrial sectors.

- Define the potential Remanufacturing market in the Basque Country, the criteria related to process organisation and the best Remanufacturing practices at international level.

- Develop a practical guide of Remanufacturing technologies.

- Define the issues to be taken into account for the efficient management of logistical and productive operations of a Remanufacturing system.

- Draw up a roadmap on R&D & Innovation needs for Remanufacturing in the Basque Country.

- Apply the analysis developed in the foregoing points to CEGASA.

RESULTS

RESULTS

- 197 companies with Remanufacturing potential were identified and classified into three groups: 42 high potential companies that remanufacture; 33 high potential companies that do not remanufacture; and 122 medium potential companies with no remanufacturing companies.

- Product datasheets for 40 companies were drawn up including their Remanufacturing potential, market penetration and technologies necessary for market penetration.

- Publication (by IHOBE) of guidelines for the implementation of the efficient logistics-production chain of the Remanufacturing system, and of a guide containing operational protocols to select the technologies applicable to the remanufacturing process.

- Cost savings of 3% and market share increase of 3% in its application to lithium battery remanufacturing cases at CEGASA.

CONCLUSIONS

CONCLUSIONS

- The Basque Country has a high Remanufacturing potential to be exploited.

- Remanufacturing is not often seen as a strategic activity by companies despite the profitability it brings to OEMs.

- Remanufacturing pilot projects need to be launched in industrial sectors to disseminate their potential. The REMANEX project has been undertaken to promote Remanufacturing in Basque industrial companies, and a guide for excellent Remanufacturing in the Basque Country has been developed and applied.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET