RESTYLING

EXTENDING THE SERVICE LIFE OF TICKETING MACHINES

Ticketing and payment management machines help companies using them (public car parks, university or company canteens, sports centres, music events, hotels and restaurants, pharmacies and tobacconists, among others) to manage the access and/or payments by users of a specific service. SITECO, manufacturer of this type of machines, offers its customers renting services, maintenance and on-line guidance, and its products are manufactured with robustness and durability criteria. For SITECO, it is important to work with customers of its own machines that were installed 15 or 20 years ago, whose renewal is necessary, while the sector, in general, has seen the entry into the market of competitors with significant price reductions.

SITECO has led RESTYLING, in collaboration with the circular economy consultancy, ZICLA, and the specialist in Life Cycle Analysis(LCA), GRUNVER SOSTENIBILIDAD.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Extend the life of SITECO machines and thus avoid the generation of electrical and electronic waste, whilst retaining the customers of its older machines by offering more environmentally friendly and more attractively priced machines.

- Diagnose the technical needs of the reconditioning process.

- Perform the reconditioning process on at least 6 real SITECO machines.

- Customer validation of the operation of the reconditioned machine in different applications.

- Know the costs of the process.

- Position itself in the market as a recognised direct supplier of reconditioning services.

RESULTS

RESULTS

- Savings of 94 kg of CO2 equivalent emissions for each reconditioned machine compared to the manufacture and sale of a new machine.

- Reconditioning of 4 5RC machines and 2 mini RC machines. The 6 machines have been placed on the market after being adapted to the needs of a customer who has been offered the reconditioned product instead of a new machine.

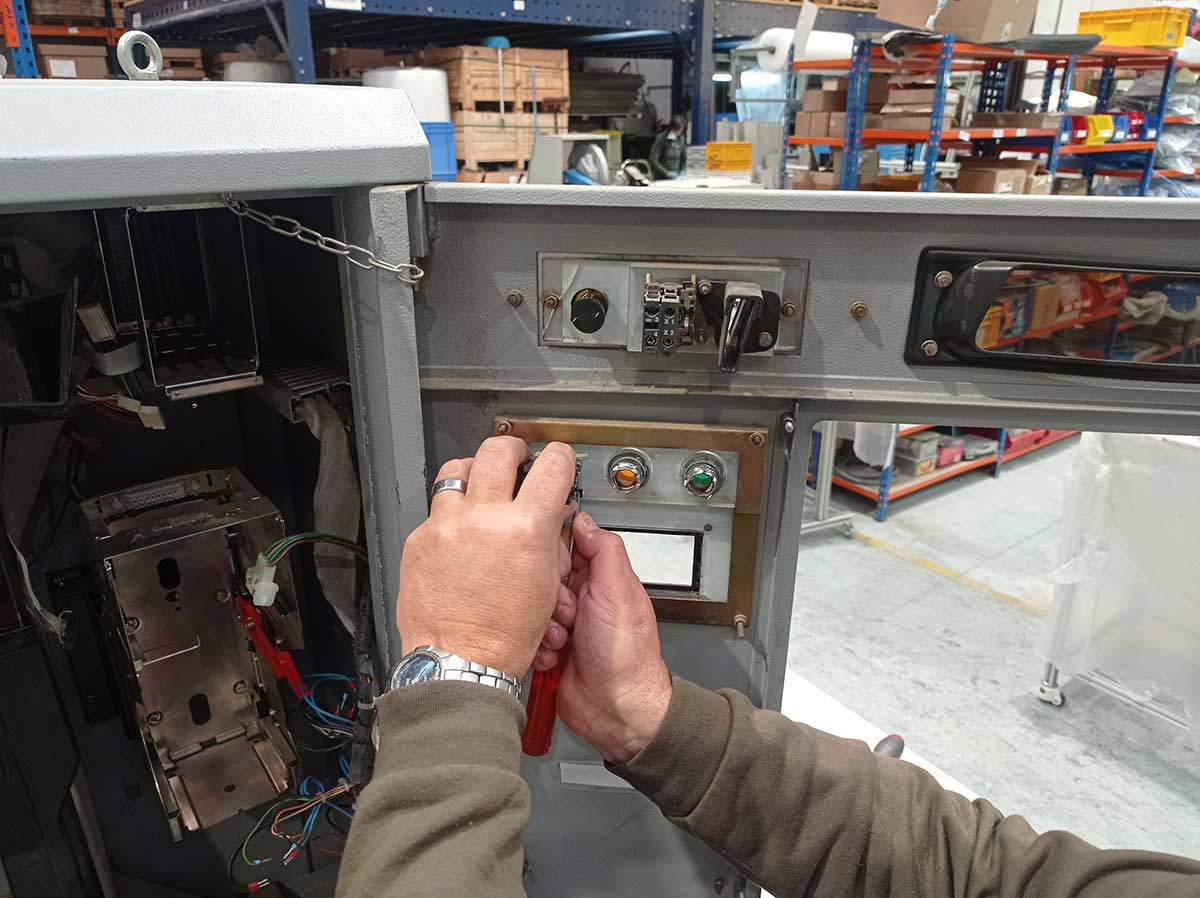

- Reconditioning protocol for internal work in the company that has been implemented, where the dismantling processes and the destination of the parts (recycling, spare parts for other old machines at the customer’s premises, or parts for reconditioned machines) are recorded.

- Results of the analysis of the reconditioning process of 1.75/5 for general factors, and 1.98/5 for factors related to reconditioning according to the REMANEX methodology provided by IHOBE. The best performance by category is resource management (2.75/5).

- Contribution of 14% to the company's turnover in collection management and ticketing machines.

CONCLUSIONS

CONCLUSIONS

- The reverse logistics of the process is key to its economic and environmental viability: taking advantage of the means of transport in which a reconditioned machine arrives at the customer company to collect the old machine and transfer it to the plant for reconditioning and offer it to the next customer.

- The potential for improvement in reconditioning processes is wide-ranging, and this has been highlighted in RESTYLING by means of the REMANEX questionnaire prepared and provided by IHOBE, whose lower compliance factors are now part of in-plant improvement.

- The management of parts and components in stock is always a key factor, but it has become especially important because of the supply crisis. In this respect, the model proposed by SITECO, which includes stockpiling spare parts from old machines for use in those customer companies that are not yet replacing their ticketing and collection machines, is particularly interesting.

- SITECO has participated in the two ZIRKULARRAK exhibitions organised by IHOBE in 2022 to disseminate and promote the value of circular products designed and manufactured in the Basque Country, with the placement of a reconditioned machine from the activities carried out in RESTYLING.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET