EMBER

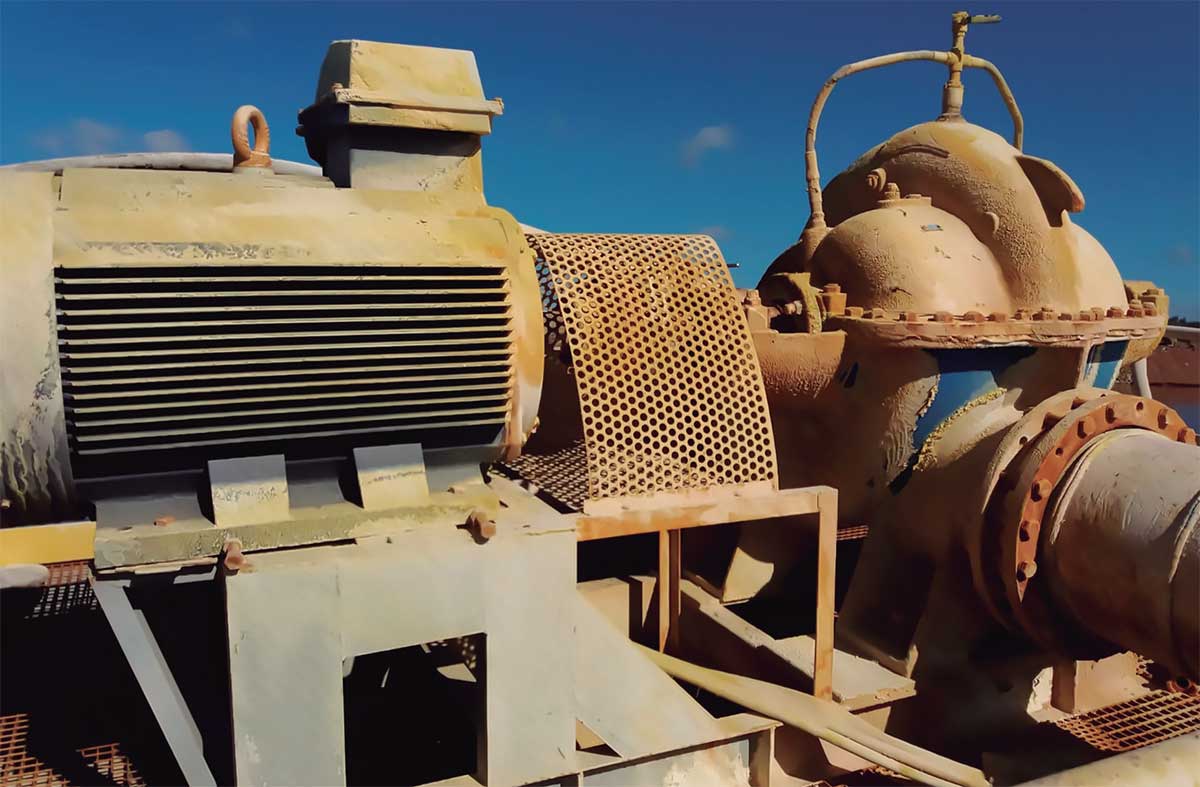

CENTRIFUGAL PUMPS REMANUFACTURING

INDUSTRIAL REMANUFACTURING PROCESSES ALLOW THE RECOVERY OF A LARGE PART OF A PRODUCT value in the form of materials, energy and knowledge stored in the product during its design and manufacturing process. EMICA, an expert manufacturer of centrifugal pumps, is aware that remanufacturing has advantages for the customer, who obtains a product at the cutting edge of technology at an affordable price and in many cases, of higher quality than new ones, and with a smaller environmental footprint; besides, the manufacturer reduces manufacturing costs, achieves improved productivity and higher quality products, develops new lines of business and anticipates environmental legislation.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Testing the feasibility of setting up a remanufacturing unit to use centrifugal pumps that have reached the end of their useful life and whose components can be reused for the generation of a new product.

- Reduce the amount of material used in manufacturing.

- Provide higher added value by incorporating Industry 4.0 features into centrifugal pumps.

RESULTS

RESULTS

- Savings of 70% in raw materials (mainly high-quality cast iron) and 203 kg of CO2 equivalent from re-manufacturing each centrifugal pump.

- Definition of a remanufacturing procedure (including disassembly, cleaning and assembly) including setting up and unifying criteria to diagnose

- Development of sensors to improve preventative maintenance of remanufactured pumps.

CONCLUSIONS

CONCLUSIONS

- The remanufacturing process consists of restoring a worn out (failed, end-of-life, obsolete or scrap) product or component to a level of performance and quality equal or superior to that of a new product; offering an equal or superior warranty. The EMBER project implementation has shown that remanufacturing is feasible and economically interesting for EMICA.

- Distribution and maintenance channels are important for the implementation of remanufacturing processes. Thus, scaling up the volume of units is complicated for EMICA since it is a manufacturing company and not an equipment maintenance provider, which makes it difficult to identify potential equipment to be remanufactured and initially limits the market to client companies that request equipment diagnostics to assess further steps.

- Likewise, EMICA operates on an international market with a distribution network that can slow down the implementation of remanufacturing requirements on equipment, especially in developing countries.

- Having a remanufacturing process distinguishes EMICA from multi-brand repair shops, as it provides the equipment with a differential value compared to a standard repair, and highlights the robustness and reliability of the company’s equipment. Profitability of remanufacturing has been demonstrated, with activity scalability yet to be implemented.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET