KOOPMAT TERMIC

USING RECYCLED TEXTILES FOR THERMAL INSULATION

THE NON-REUSABLE FRACTION OF THE TEXTILE WASTE COLLECTED BY KOOPERA contains natural fibres such as cotton, wool and blends of cotton with man-made fibres, which can be used in thermal insulation. However, currently there are no facilities collecting post-consumer textiles for reuse and production of a byproduct for this application. Given its high environmental footprint, the construction sector is continuously looking for environmentally sustainable building material solutions.

KOOPERA, a leading insertion company in treatment and reuse of post-consumer textiles, is leading KOOPMAT TERMIC, with the collaboration of the energy rehabilitation specialist RENER and TECNALIA Technology Centre.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

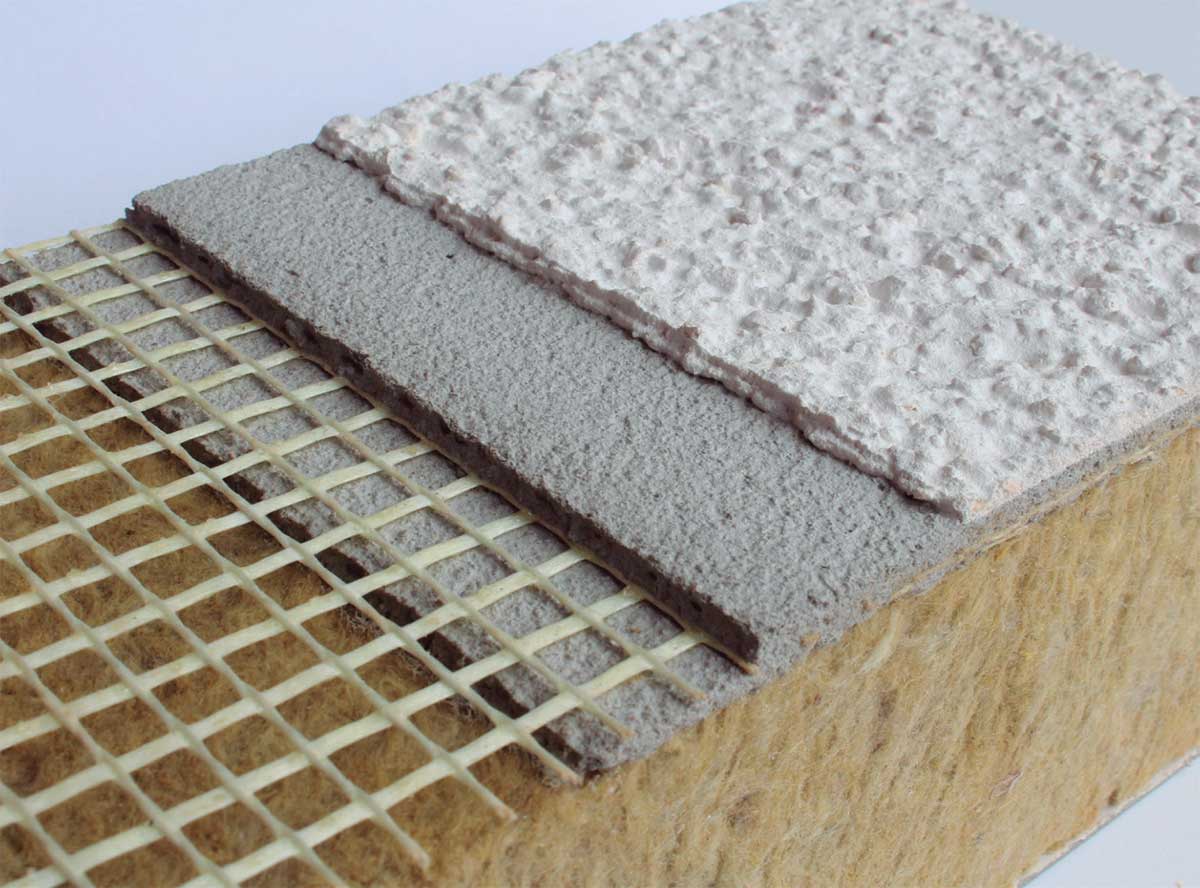

- Produce and validate thermal insulation panels to be used in outdoor construction elements or party walls, manufactured from post-consumer recycled textile material that is currently not reusable.

- Reduce the carbon footprint of post-consumer textile waste management.

- Generate new jobs for people in situations of vulnerability or social exclusion.

- Reduce the environmental impact of potential worksites using the insulation material obtained.

- Setting up a partnership between organisations from two sectors such as textiles (KOOPERA) and construction (RENER).

RESULTS

RESULTS

- The technical specifications of the material and the end product have been defined.

- Development and implementation of the complete process, which includes: selection and classification of post-consumer textile material; raw material adaptation; textile flock manufacturing and treatment: insulating material manufacturing, validation, characterisation and on-site installation.

- Obtaining a textile panel with an acoustic and thermal performance that is very good and even better than other textile insulation products available on the market.

- The fire rating obtained is also superior to other insulations of this type, although it is below other mineral wool insulations with very high fire reaction performance.

CONCLUSIONS

CONCLUSIONS

- The contribution of the value chain from positive work with external suppliers such as Triturats La Canya, RMT and Logrotex, has been fundamental in achieving the objectives set.

- KOOPMAT TERMIC has successfully demonstrated that some textile waste donated by the public can be recycled into thermal and acoustic insulation panels.

- The process steps are technically feasible, but the panel composition and technical performance need to be optimised. This will require determining the final manufacturing process, defining the companies to rely on, as well as working from a LCA and product approval perspective.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET