ALSPF

SUPERPLASTIC FORMING TO MANUFACTURE ALUMINIUM COMPONENTS FOR THE RAILWAY AND AUTOMOTIVE INDUSTRY

THE CURRENT TREND IN THE RAILWAY AND AUTOMOTIVE SECTOR IS THE INCORPORATION OF ALUMINIUM (Al) to replace polymeric composite materials used in recent years. This is due to the need for recyclability, which Al provides compared to polymers. The engineering firm EKIDE has worked alongside MONDRAGON UNIBERTSITATEA to demonstrate the viability of the superplastic forming process to make this transition possible.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Demonstrate the feasibility of SPF (superplastic forming) for the manufacture of Al components with excellent mechanical properties for the railway and automotive industries.

- Save 26 tonnes of materials per year.

- Reduce energy consumption by 74% - 82%, thanks to shorter cycle times and lower furnace consumption.

- Minimise the weight of existing products by up to 33% and improve mechanical and flame-retardant properties.

RESULTS

RESULTS

- Reduced processing time by almost half (55 to 26 minutes) with satisfactory technical results.

- Reduced consumption by 16 tonnes of Al per year thanks to the use of the new technology.

- Characterisation of two new materials in superplastic state.

- Design of manufacturing process and moulds to produce scaled parts and study of the process limits. Manufacture of moulds, system fine-tuning and manufacture of demonstrators of a railway part in different Al alloys using SPF.

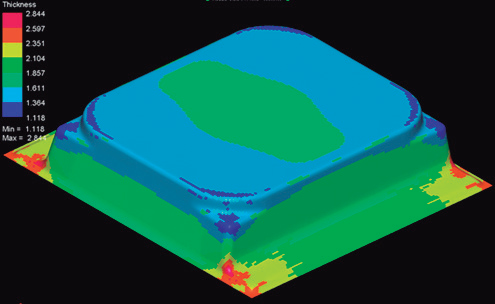

- Highly accurate process simulation.

- Using a steel mould not prepared for high temperature, 20 tests were carried out without any problems.

CONCLUSIONS

CONCLUSIONS

- The feasibility of the solution has been demonstrated by favouring the use of aluminium for forming and increasing the possibilities of recyclability as a composite substitute.

- Knowledge of superplastic forming has been obtained through a simulation using Abaqus® and Pam-Stamp® (already known simulators but not for this type of transformation).

- Alloys that are more sensitive to temperature heterogeneities in the mould may generate breakage when forming.

- Aluminium seems the future alternative to replace composite in the railway sector, offering better mechanical properties than composite, while being recyclable at the end of its useful life at the same time, and reusable for other applications.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET