BRomoX

SEPARATING PLASTICS WITH BROMINATED FLAME RETARDANTS FROM WEEE

THE DIRECTIVE 2012/19/EU AND ROYAL DECREE 110/2015 ON WASTE ELECTRICAL AND ELECTRONIC EQUIPMENT (WEEE) focus on the identification and separation of plastics containing Brominated Flame Retardant (BFR) materials, which are part of printed circuit boards, plastic housings or connectors and cables. The European regulation on Persistent Organic Pollutants (POPs) requires the separation of plastics containing BFRs, and in particular, polybrominated diphenyl ethers (PBDEs) for recycling of WEEE materials and components. Materials with PBDEs content higher than 500 ppm (> 0.1% of Br) are defined as hazardous (Directive 2011/65/ EU or RoHS 2) and this figure set to go downwards, since this Directive is under review (COM(2021) 656, Oct. 2021) and proposes a further reduction of PBDEs to 200 ppm. In order to meet these and future constraints, plastic recycling demands new technologies, as it will be very difficult to achieve this distinction with the usual treatments. Technology based on X-ray sensors is increasingly used for this purpose, as it guarantees the best results by sorting materials by their atomic density.

ZABOR RECYCLING is a company of the OTUA GROUP specialising in recycling of electrical and electronic cables and components with copper and aluminium content. In BRomoX, it has worked with INATEC FOUNDATION and GAIKER Technology Centre.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Implement a system for the identification and separation of brominated plastics that will serve as part of the end-of-life decontamination process for WEEE.

- Recover up to 97% of plastic fractions with BFR content, separating them from the fractions that do not have it in order to recycle them within the polymer market.

- Set up the first facility to reduce BFR content in plastics from WEEE in the Basque Country.

RESULTS

RESULTS

- In-depth study of the plastic fractions from WEEE, sampling and characterising suffi cient quantities of polymeric waste, reference and real samples, to be used with the proposed technology, with created and real-life waste streams.

- Feasibility of XRS (X-Ray Sorter) technology to define a treatment line capable of achieving a polymeric fraction from WEEE with bromine content below 0.1%, making the waste non-hazardous.

- Correct calibration of XRS technology for the identification of bromine compounds in plastic matrices.

- Saving of 8,400 tonnes of CO2e per year thanks to the recovery of materials involved in the process.

- Implementation of a brominated polymer separation process for decontamination of WEEE waste using XRS technology. The work carried out at BRomoX has granted ZABOR Recycling an authorisation to treat plastic fractions containing BFRs (an Authorisation approved by the Basque Government in 2020).

- Increased company’s market share by 5%.

CONCLUSIONS

CONCLUSIONS

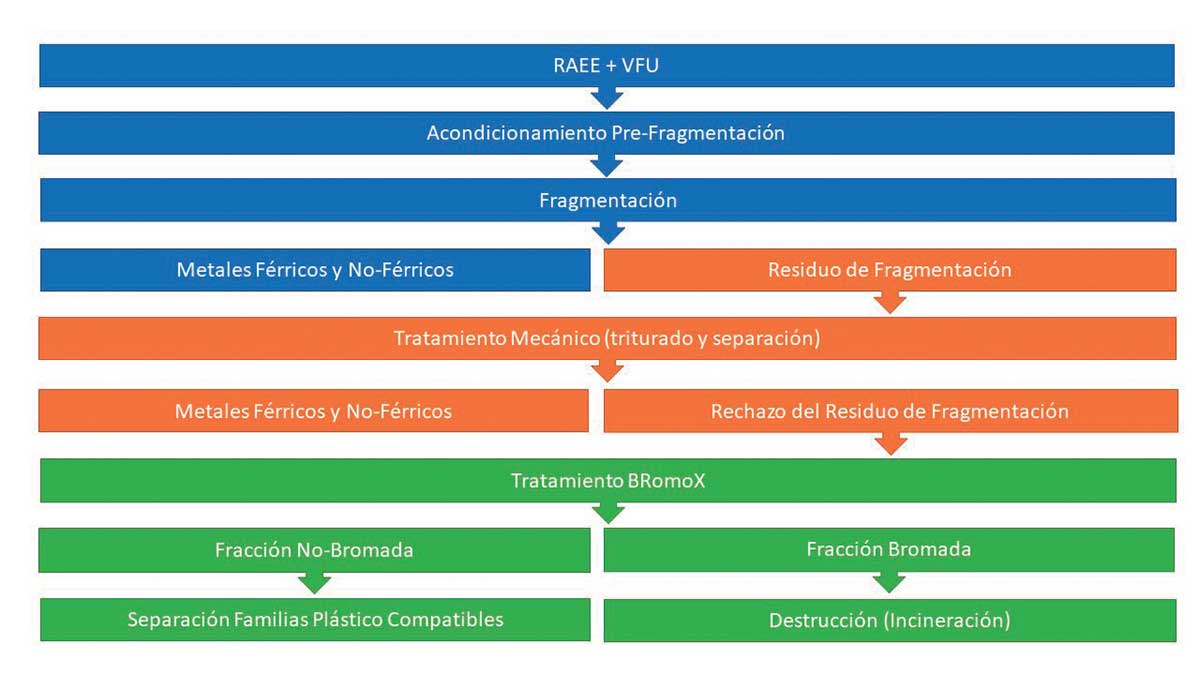

- BRomoX will now focus on the design of a viable treatment scheme to meet the new targets demanded by current and forthcoming legislation on BFR content in recycled plastics from WEEE and End-of-Life Vehicles (ELVs), where research is in progress to find the best techniques to separate brominated fractions from plastics. The BRomoX treatment will be part of an overall treatment which will go further than the current state-of-the-art knowledge on recycling plastic rejects from WEEE and ELVs shredder waste to prevent these materials from ending up in landfill.

- The final aim of the new initiatives will be to close the recovered material cycle: sorting the material into families of compatible plastics to demonstrate their use as raw material for the manufacture of new parts for new EEE and other types of parts applicable to other consumer sectors.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET