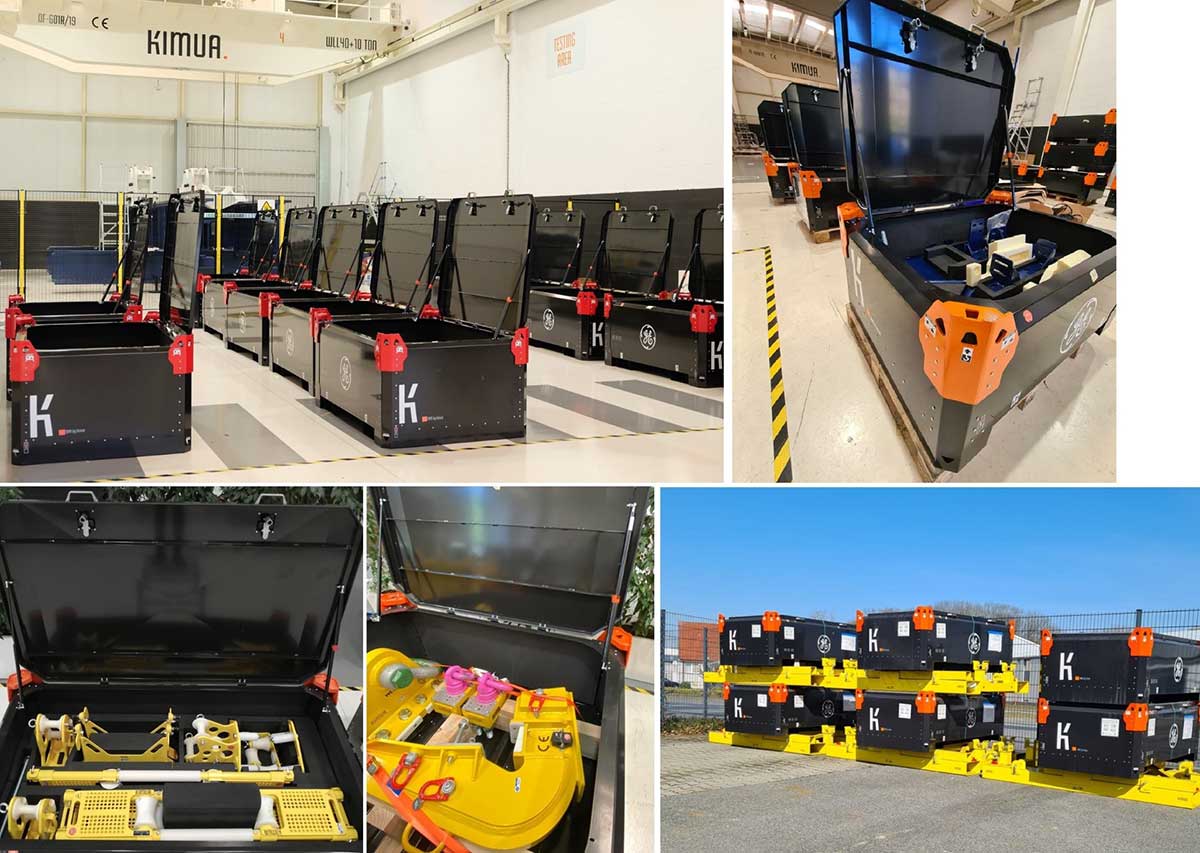

ARINBOX

SAFE AND EFFICIENT LOAD LIFTING AT WIND FARMS

The offshore wind power industry involves a wide variety of ships and vessels, equipped with cranes of different types and sizes, to facilitate the handling of components and other loads. During the installation of the turbines, jack-up vessels play a key role. They are colossal vessels equipped with large capacity cranes to assemble the main components, which are the bulkiest and heaviest ones, in the middle of the ocean. Other types of vessels with a more limited capacity support offshore operations, not only in the installation phase, but also in operation, maintenance and decommissioning, and, like in the oil and gas industry, cargo handling from these vessels to the platforms (and vice-versa) is performed with cranes of smaller capacities, whereby 2.5 and 3 tonnes are the most common. Finally, there are the service cranes installed on the turbines themselves, which do not usually exceed a capacity of 5 tonnes.

Nowadays, loads are transferred by using either special bags or very heavy lifting boxes, which make transport, lifting and storage operations difficult in this type of industry, with the additional disadvantage that they are often not certified for use as hoisting equipment. On the other hand, in the onshore wind power sector, the pallet is the most commonly used means of transporting loads to the land where the wind towers are located. Once there, heavy bags or boxes are usually used to lift tools and other components to the turbine. Onshore turbine cranes usually have an even more limited capacity of 1 to 2 tonnes at most.

Facilitating these activities, guaranteeing a light and easy to handle system that is competitive and meets the requirements of the target market in technical-economic terms, as well as in terms of safety, agility and handling time is a need that has been expressed by companies in the wind power sector. Any modification to the existing hoisting system entails high costs for the installations. KIMUA, a leading company in the handling, lifting and transport of loads, promotes ARINBOX, a project in which IK INGENIERÍA, a company specialising in Life Cycle Analysis (LCA), has collaborated.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Develop a modular, light, resistant and easy to handle system for transporting, storing and lifting loads from 1 to 3 tonnes, that offers excellent safety conditions for the customer and is competitive in the onshore and offshore wind power market.

- Improve the stackability and collection method of existing systems.

- Facilitate the securing of loads transported on the decks of ships.

- Develop a system that is capable of being industrialised and is price competitive.

- Minimise energy consumption thanks to the agility and speed of use, by not having to use more than one system to carry out different handling and lifting tasks at wind farms.

- Reduce engineering design hours by 90% through the development and implementation of new representation methodologies for flat surfaces and spaces.

- Offer customers a lifting tool certified as such, with the aim of reusing it in different projects.

RESULTS

RESULTS

- Design and development of a multifunctional system in a "compact" format with a low specific weight for applications in the wind power sector with heavy loads.

- Reduction in environmental impact of 11% for semester 3 and 28% for semester 10 compared to the initial case, depending on the impact category considered.

- Invoicing of €768,000 associated with estimated sales of ARINBOX systems in 2026.

CONCLUSIONS

CONCLUSIONS

- Product parameterisation significantly reduces engineering design hours in the design of ARINBOX models.

- Customers demand lower environmental impact alternatives, so their interest in the implementation of ARINBOX reconditioning systems is high. It is therefore important to study the wear and tear of the gearbox, the reason for the wear and tear and potential improvements.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET