RECYMUFLA

RUBBER-FREE HIGHLY RECYCLABLE WASHING MACHINE DOOR SEALS

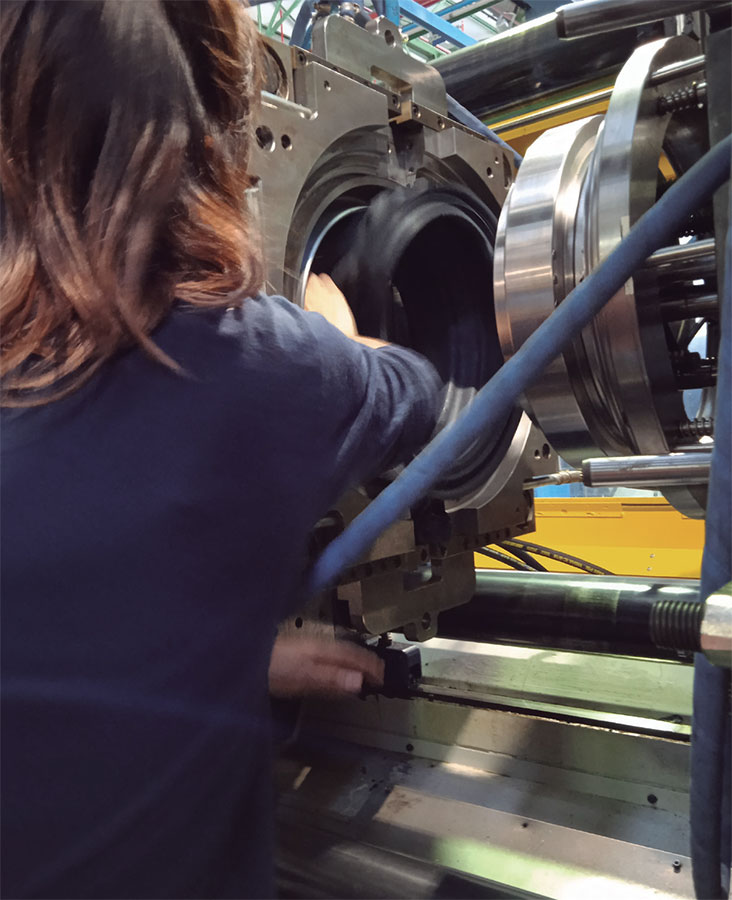

DOOR SEALS (OR MUFFLERS) FOR LOADING CLOTHES IN DOMESTIC WASHING MACHINES ARE MADE OF EPDM RUBBER (ethylene propylene diene monomer (M-class) rubber), a non-recyclable rubber as its vulcanisation process is irreversible. The washing machine seal is a mature product that has not been innovated in the market for a long time. RECYMUFLA proposes to increase the recyclability of the washing machine gasket thanks to the development of thermoplastic elastomer (TPE) gaskets.

This project responds to the need to incorporate a sustainability variable into CIKAUTXO’s household appliances. There is no company in the world currently manufacturing washing machine door seals that offers this type of innovation. Therefore, if successful, this project would reach a global scope that would allow CIKAUTXO, a company specialising in the development and production of rubber and plastic components for various applications, to achieve a leading position and a competitive advantage.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Develop a new range of rubber-free, highly recyclable washing machine seals that comply with watertightness, flexibility, resistance to vibration and abrasive wearing requirements.

- Reduce energy consumption and noise by 15% and 20%, respectively, during the working cycle of washing machines.

- Optimise the current extrusion process for the new recyclable TPE material.

- Reduce the manufacturing process lead time by 12%, cutting down energy consumption and CO2 emissions in the factory.

- Launch the new range of sustainable seals to the market by 2022.

RESULTS

RESULTS

- Improved abrasion resistance of the TPE-based material, in addition to the technical requirements set for the product.

- Set up injection moulding process conditions of washing machine seals with the new TPE-based material.

- New geometry design of the washer seal for the new material.

CONCLUSIONS

CONCLUSIONS

- The development and characterisation of the material requires close collaboration with the R&D unit (CIKATEK) due to the necessary transfer of material and technology knowledge (extrusion and injection) to CIKAUTXO team, specialised in the injection process of the EPDM rubber material.

- The development of RECYMUFLA resulted in further knowledge of extrusion compounding during the preparation of multiple TPE-based formulations with different thermoplastics, elastomers (SEBS) and process additives and functionalisation.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET