FRAGPLAS

PLASTIC SEPARATION IN END-OF-LIFE VEHICLE WASTE

END-OF-LIFE VEHICLES (ELV) MANAGEMENT INVOLVES DECONTAMINATION STAGES OF HAZARDOUS SUBSTANCES and components as well as material recovery. It is the first step in shredding and grinding the remaining decontaminated vehicle which is generally followed by several separation steps. This is a scheme oriented towards the recovery of metallic fractions where non-metallic fractions have come second. Thus, in 2012, only 12% of the 37,000 tonnes generated from these streams were recycled; and 34% went to energy recovery while the remaining 54% ended up in landfills. On the other hand, modern vehicles contain more and more plastics (up to 10-15% of their mass, depending on the model), and the proportion of these materials will be increasing in waste streams resulting from their end-of-life treatment.

RECYCLAIR has led FRAGPLAS in collaboration with GAIKER Technology Centre for the project execution.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Validate a technological solution applicable on an industrial scale to obtain commercial quality polypropylene (PP) plastic concentrates from residual fractions generated in the treatment of ELVs shredder residue and other complex products.

- Assess automatic systems based on advanced sensors for continuous recognition and selection of PP mixed with other materials.

- Effectively identify and separate plastics from a complex mixture by polymer type, regardless of their colour, using a new optical sensor capable of recognising dark or black coloured plastics, a task that conventional automatic systems cannot perform.

RESULTS

RESULTS

- PP with purity above 95% was obtained along with a recovery yield of more than 90%.

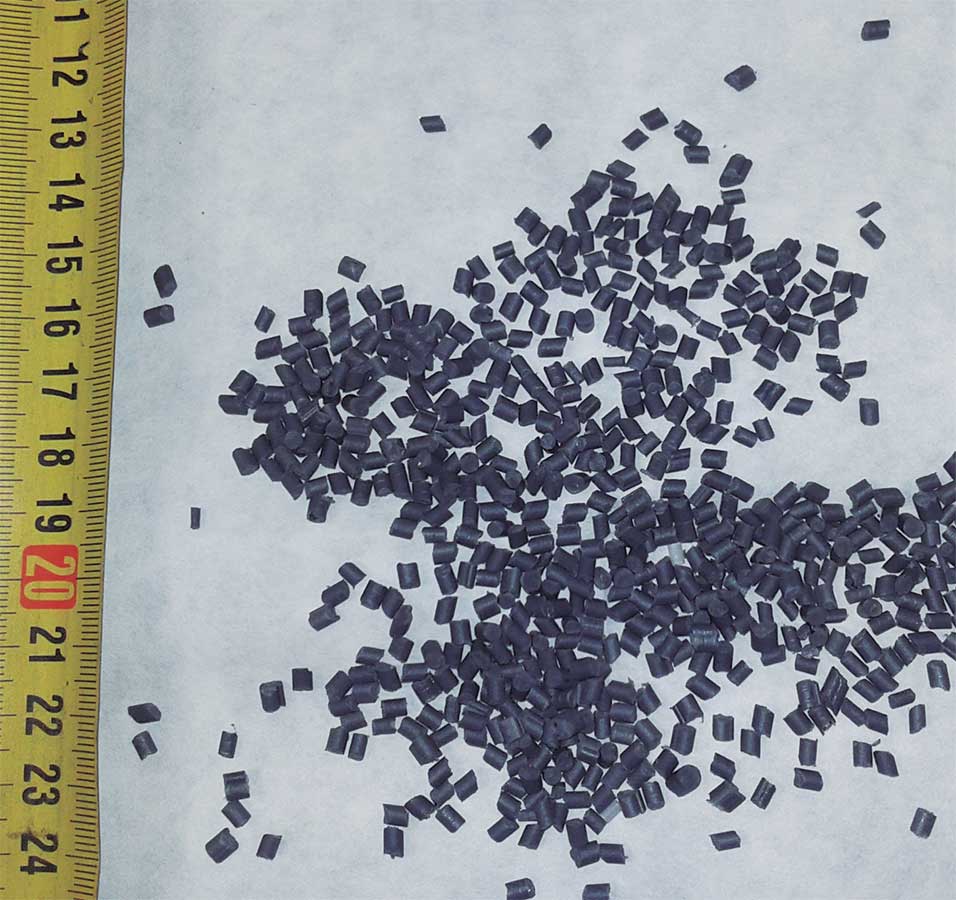

- This purity was further refi ned by densiometric separation techniques, resulting in a recovered PP with experimental purity of 99% and it was found suitable for extrusion, pelletising and injection moulding.

- Semi-industrial testing in collaboration with equipment manufacturers, using batches of residual fraction from RECYCLAIR’s treatment of shredder waste.

CONCLUSIONS

CONCLUSIONS

- The quality of recycled PP is directly dependent on the types of ELVs treated, which are manufactured at different times and with materials that vary over time. Regular inspection of streams is a limited measure when processing large volumes of bulk material.

- This issue and the wide supply of recycled plastics in the secondary raw materials market pose barriers to the economic viability of the new process. However, industrial scale tests by FRAGPLAS will continue to verify if the qualities and yields obtained are maintained.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET