GREEN PACK

OPTIMISED ENERGY CONSUMPTION IN PET BOTTLE BLOW MOULDING

THE PRODUCTION OF POLYETHYLENE TEREPHTHALATE (PET) bottles can be carried out in two independent stages, whereby the preform injection and blowing are performed on machines that can be optimised separately. The preforms are positioned in a transport conveyor from an automatic feeder. Then preforms pass through a system of furnaces with IR lamps where they are softened and finally stretched and blown with high-pressure air into a mould. This is the technique used for the manufacture of bottles of water, soft drinks, juice, etc.

GREEN PACK is a project managed by UROLA, a cooperative that designs and creates solutions for the manufacture of containers using blow moulding technology, where GALBAIAN, a consultancy specialising in industrial property and the AZTERLAN Technology Centre, have also participated.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Obtain a new design of PET bottles and moulds to allow the use of high-pressure compressed air to be reduced from 40 to 25 bar in the bottle manufacture, with energy savings of around 37%.

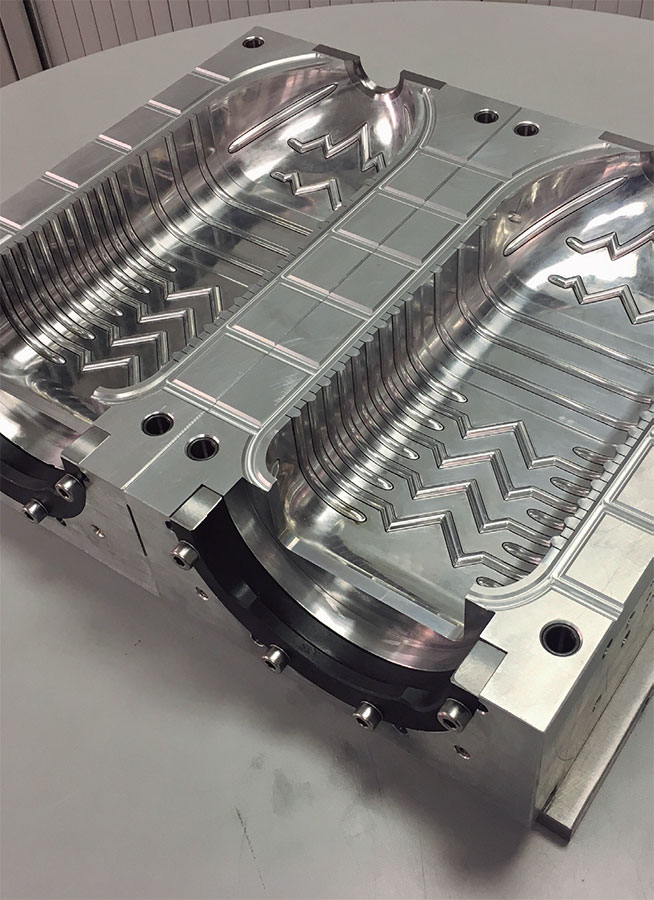

- Eco-design of the bottle manufacturing process by targeting both the container design (allowing it to be blown easily) and the mould itself (increasing the evacuation capacity of the air trapped between the container and the cavity).

- Identify the right geometry of the bottom of the container to be formed correctly without the need for high internal pressure, as the impact of this effect can account for 40% of the project’s success rate.

RESULTS

RESULTS

- The mould was developed and manufactured according to eco-design criteria.

- A pilot test was conducted in conditions similar to real conditions in a URBI-2L machine installed in a corporate client facility.

- Low blowing with a capacity of 2,100 bottles per hour would cut electricity consumption by approximately 13.1%. For the functional unit under consideration, this represents a saving of 117.69 MWh, while GHG emissions are reduced by 41 tonnes of CO2e.

- Environmental disadvantages in terms of depleted mineral and abiotic resources, ecotoxicity (water) and human toxicity (non-carcinogenic).

CONCLUSIONS

CONCLUSIONS

- The GREEN PACK solution makes it possible to reduce the size of the compressor at the time of purchase, reducing installed power from 110 kW to 75 kW. The savings obtained in different pressure ranges allow for a two-year payback for the corporate client in the event of replacing an existing mould.

- The need to introduce new machining steps during mould production undermines to a certain degree the overall environmental performance of the solution.

- Further steps to be taken at GREEN PACK will focus on correct industrialisation and standardisation, and adjustment of operating costs.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET