STIRLADLE

ON-LINE STEEL STIRRING CONTROL SYSTEM

RESEARCH INTO THE OPTIMISATION AND MONITORING OF CURRENT STEEL stirring processes in the ladle have been conducted for years to ensure better process indicators and the correct diagnosis of equipment conditions. However, practical implementation has not achieved the expected theoretical results, and the process continues to entail excessive consumption of raw materials and energy. This is a poignant issue for SIDENOR and for the steel industry, as new environmental regulations, a demand for higher quality products and high competition on the market, demand modernisation and the adoption of new technologies. SIDENOR is a company dedicated to manufacture and transform steel, leading the European segment of long special steel products.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

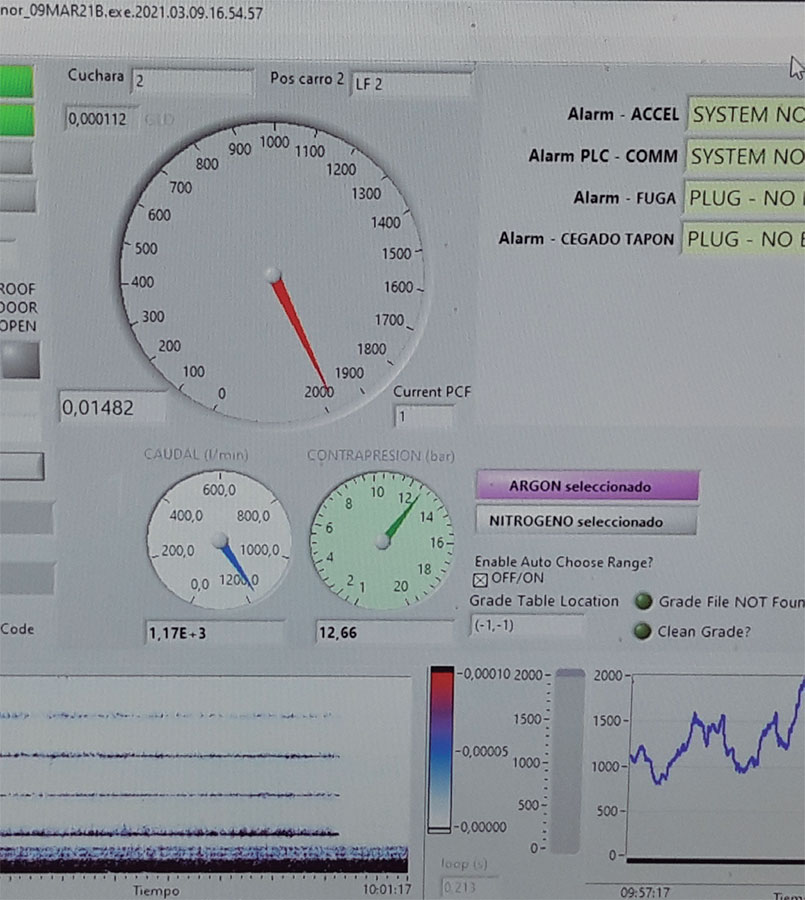

- Develop and implement a monitoring system for accurate control and characterisation of the stirring energy of the steel ladle; and analyse stirring information provided by the smart sensors implemented.

- Improve productivity, thanks to the optimisation and control of processes through new monitoring systems.

- Improve steel quality index, and therefore reduce defective steel, which will lead to better resource efficiency.

- Improve energy efficiency and reduce environmental impact.

RESULTS

RESULTS

- Technical validation of the monitoring system for the control and accurate characterisation of steel ladle stirring.

- Development of an interface to differentiate vibrations caused by general process gases.

- 0.4% reduction in production scrap, which means a saving of 3,000 tonnes of steel per year and more than EUR 0.5 M per year.

- Annual of CO2 emissions by 641 tonnes.

- Reduction by half in the number of reprocesses carried out and substantially improved castability.

CONCLUSIONS

CONCLUSIONS

- The IT architecture in the installation is key to integrate data from the vibration sensors and other production control systems.

- Technical parameters affecting the vibration pattern may require correction factors.

- The newly developed system can be applied to clean steels or steels with high quality requirements to improve steelmaking performance, adjust steel process production for the transition to climate neutrality or preparation of raw materials to produce green steels.

- STIRLADLE opens a new possibility of installing sensors of the same type in other steel facilities in the Basque Country.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET