TERMOSLAG

ON-LINE SLAG DETECTION SENSOR IN EAFs

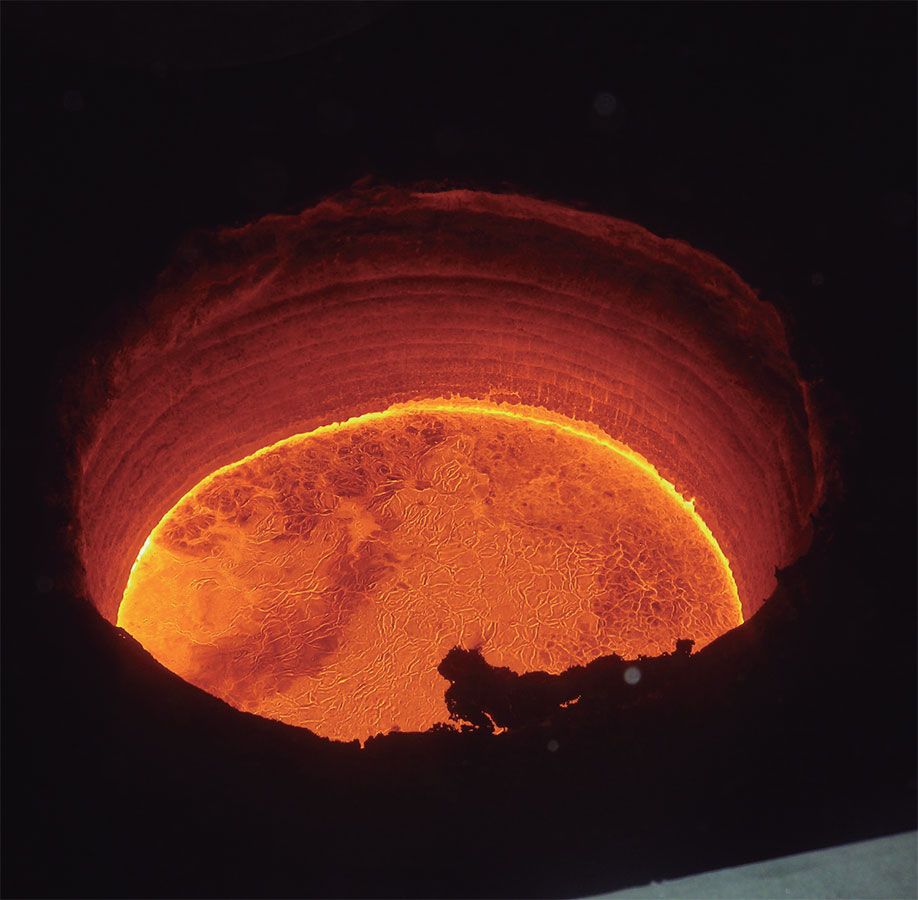

THE TAPPING PROCESS IN ELECTRIC ARC FURNACES (EAF) has been extensively researched, but operationally it is still not possible to detect the exact moment when slag starts passing from the furnace to the ladle, and this prevents process optimisation. The current slag monitoring equipment is a thermographic camera, which only measures slag passing through the front surface of the jet during tapping, so that anything that passes inside or through the rear of the jet is invisible to monitoring. These current limitations prevent the information collected on-line from being representative of what is actually happening during tapping.

SIDENOR is a company dedicated to manufacture and transform steel, leading the European segment of long special steel products.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Achieve on-line control of slag movement during the tapping of liquid steel in EAFs through Eccentric Bottom Tapping (EBT) by developing an on-line sensor.

- Reduce the amount of slag passing into the steel.

- Reduce raw material and energy consumption by optimising the process as much as possible.

- Improve steel quality by avoiding Si or Mn recoveries from slag to steel due to slag passage.

RESULTS

RESULTS

- Overall, significant improvement in terms of internal steel quality, lower costs and more efficient use of resources have been achieved.

- Optimised secondary metallurgy processes thanks to accurate monitoring of EAF slag, a process parameter that had not been controlled until now.

- Minimised slag (up to 10%) during steel tapping by strengthening information.

- Reduced dephosphorisation, improved cleanliness and castability, increased alloy yields, reduced use of deoxidisers and lower electricity consumption. Emission savings of 970 tonnes of CO2e.

CONCLUSIONS

CONCLUSIONS

- The development of the virtual sensor has helped to optimise the refining stage, which accounts for up to 20% of total emissions in steelmaking process; and it has also facilitated an analysis of the impact of the slag movement on other parameters of the refining stage that currently could not be addressed.

- System validation is required over a longer period covering all grades and scenarios of SIDENOR’s production, so that system validity can be demonstrated in reality.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET