BeCold

MINIMUM LUBRICATION AND CRYOGENIC COOLING IN MACHINING PROCESSES

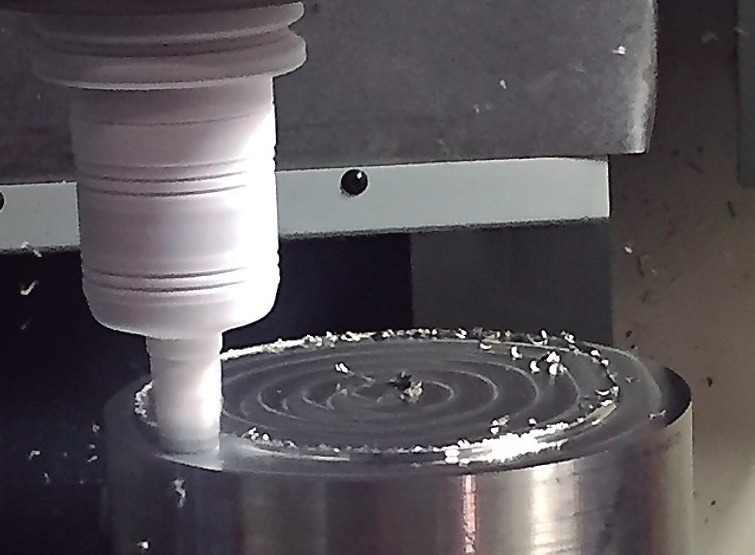

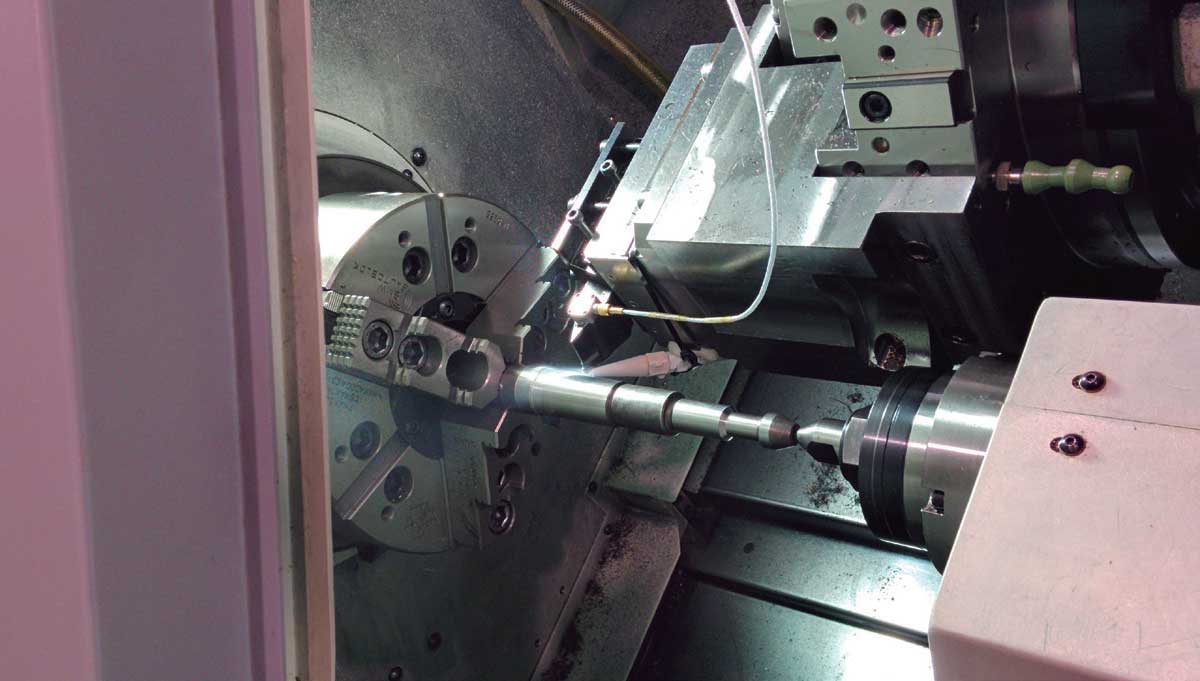

DRILL COOLANT AND CUTTING OILS ARE TWO COMPONENTS WIDELY USED IN MACHINING PROCESSES. They account for between 8% and 16% of the manufacturing costs of a part and have a negative impact on the environment and workers’ health. To address this, the design and manufacture of BeCold equipment seeks to minimise these consequences by combining minimum quantity lubrication (MQL) and cryogenic cooling.

HRE is a global supplier of industrial fluids that seeks to generate an innovation framework that promotes the development of new business lines. For this project, HRE has worked with TECNALIA Technology Centre and the Centre for Advanced Aeronautical Manufacturing (CFAA) of the University of the Basque Country (UPV/ EHU).

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Reduce negative impact from the use of cutting fluids, creating cleaner and more environmentallyfriendly environments.

- Align the company’s 2030 vision with Sustainable Development Goals.

- Expand the market using a marketing strategy to gain notoriety and brand image.

- Strengthen alliances and collaborations with technology centres and universities that contribute to product development and optimised results.

RESULTS

RESULTS

- Tool life was increased by 25% to 300% in tools used in machining tests carried out on different materials, many of which are difficult to machine and include among others: Ti6Al4V, 1.4410 super duplex steel, AISI 316 (stainless steel), AISI 4340 (Cr-Ni steel), ASP23 (HSS) steel, Ti6Al4V - CFRP, Inconel 718, and hardened steel (40HRc)

- All costs arising from the purchase, use, leakage and treatment of drilling oils were removed by up to 16 % of manufacturing cost.

- Improved working conditions, with an absence of CO2 saturation problems affecting the quality of workshop atmosphere.

- Savings of 20-30% compared to direct competitors thanks to accelerated cutting speed, reduced tool wear due to temperature control, maintained surface integrity, use of cryogenic cooling with low pressure CO2 injection, lower CO2 consumption, and simpler installation.

- Detection of national and international market potential, in countries with high metal manufacturing production and machining such as Germany or Italy.

- 4 different versions of the product were obtained so that they can be adapted to different needs.

- Validated accessories necessary for correct system operation.

CONCLUSIONS

CONCLUSIONS

- It is important to maintain fluid and constant communication with project partners and collaborators in order to achieve results as effectively as possible

- BeCold has made it possible to plan an optimal marketing strategy: market research, marketing plan, new agreements and partnerships or economic balance.

- The product’s strengths and opportunities were clearly defined on the one hand; as well as threats and weaknesses, on the other.

- Between 2021 and 2022, the first 8 units have been quoted and deals are in the process of being closed for full industrialisation (including one for Japan and another one for Costa Rica for the manufacture of medical components).

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET