ELEKTROZULAKETA

MACHINE TOOL PUNCH HOLDER ECO-DESIGN

THROUGH THEIR SECTOR ORGANISATIONS, COMPANIES IN THE MACHINE TOOL INDUSTRY have collectively embracedenvironmental improvement initiatives at pan-European level, based on extensive research and a Life Cycle Analysis (LCA) viewpoint. FAGOR ARRASATE, a leading manufacturer of cutting and forming lines, is aware of the environmental cost derived by the production installations they design, which is high in the use phase (production at client’s premises) and proportionally negligible in the construction phase. On the other hand, its own nature as a cooperative drives its social responsibility and environmental awareness philosophy, as well as a conviction to improve its relationship with the social environment.

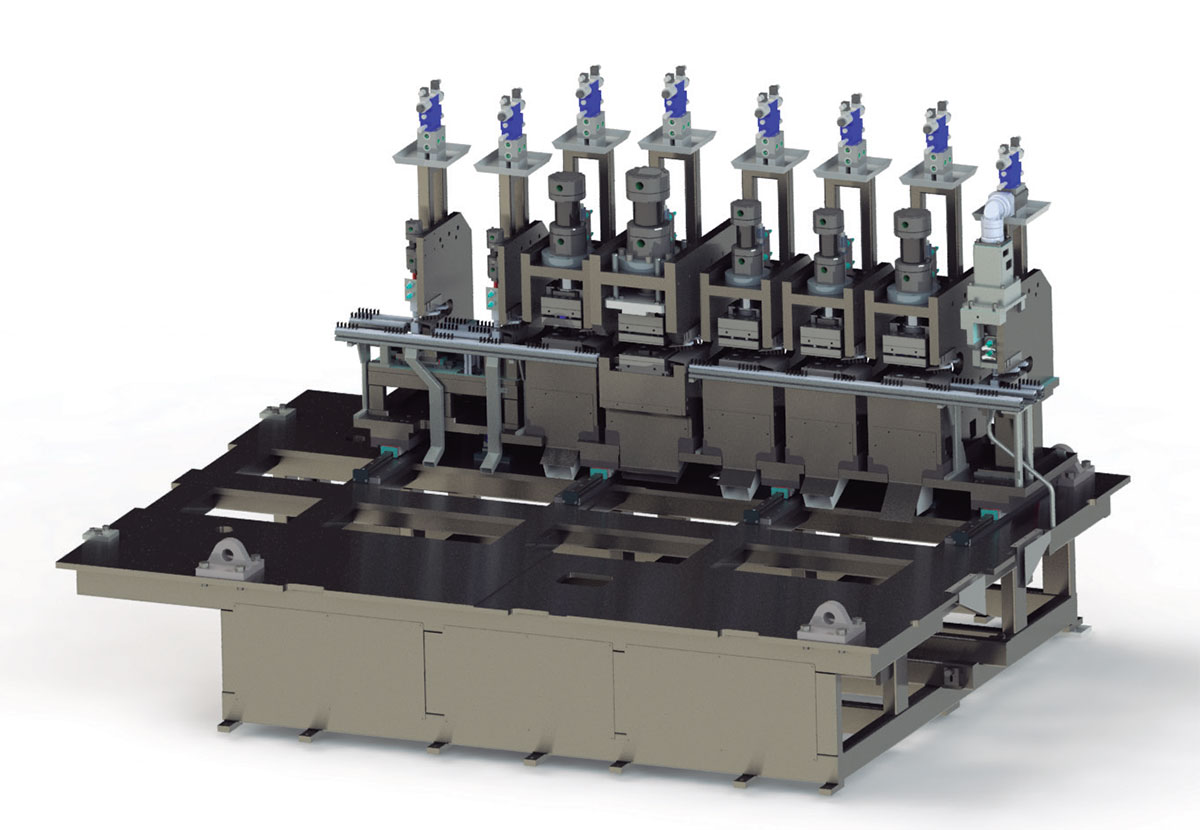

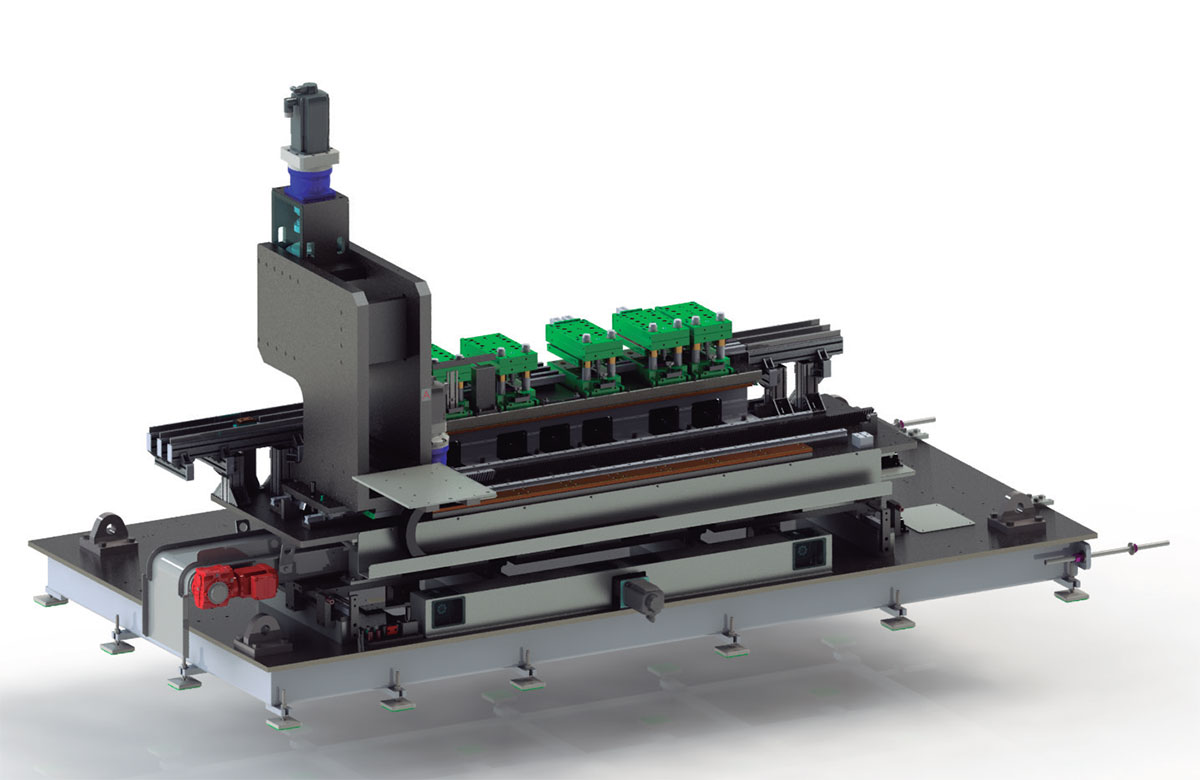

ELEKTROZULAKETA is an example of this philosophy which will be applied to the Punch Holder of an open-sided mini-press (6-10t), where the hydraulic drive has been replaced with a servo-electric drive. To achieve this, FAGOR ARRASATE has worked with the Mechanics Department of the MONDRAGON UNIBERTSITATEA Goi Eskola Politeknikoa.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Redesigning the Punch Holder product using an electric drive instead of a hydraulic drive to achieve similar technical performance (cadence, force, etc.) and efficiency improvements.

- Eliminate the use of hydraulic oils in the use phase.

- Reduce electricity consumption by more than 30% in the use phase.

- Reduce faulty products due to burrs by 30% in the use phase.

- Reduce the environmental footprint in the manufacturing phase.

- Achieve greater durability of the industrial line manufactured, including reuse.

RESULTS

RESULTS

- 37% increased energy efficiency due to the new servo-driven Punch Holder. • Reduction of defects by controlling cutting speed, improving quality, without negatively impacting cycle time.

- 34% reduction of CO2 equivalent emissions, achieving savings of 4,100 tonnes per year.

- 2% reduction in unit manufacturing cost.

- 5% contribution to the company’s overall turnover.

CONCLUSIONS

CONCLUSIONS

- The units may be diffi cult to run as the load to be applied increases, although this is not a critical limitation in punching stations.

- The incorporation of servo drives as opposed to hydraulic components implies higher training requirements for machine and maintenance personnel.

- FAGOR ARRASATE, in contact with its preferred corporate client, has designed and implemented a line equipped with electrical drives according to ELEKTROZULAKETA. Subsequently, given the advantages of the new design, all bids submitted for installations in developed countries included this option. Moreover, corporate clients’ responses have been overwhelming, and currently, in 2022, electric drives are implemented in all installations for Europe.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET