INGEBER STANDARD

ENERGY RECOVERY IN RAILWAY SYSTEMS

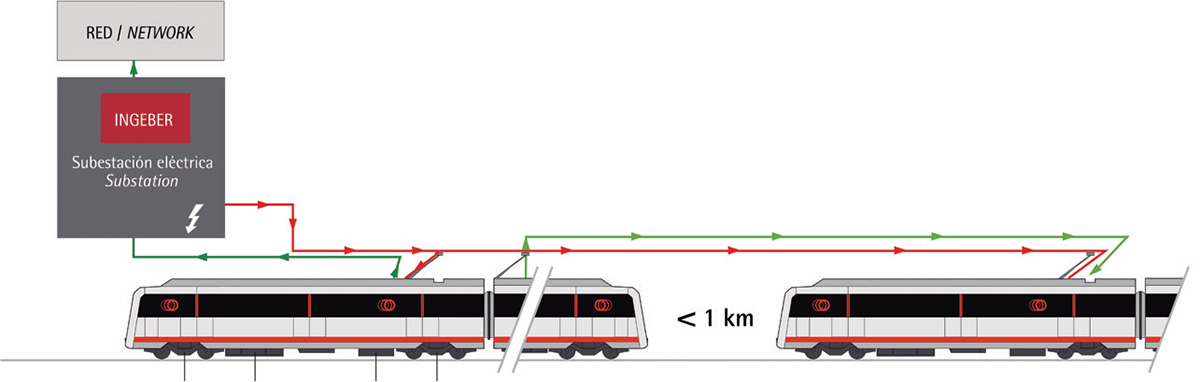

INGEBER IS A CONVERTER CONNECTED TO THE CATENARY OF RAILWAY SYSTEMS which recovers energy from braking in trains and uses it for internal consumption of installations, returning surplus to the grid. This very competitive product on the energy market was first launched in Metro Bilbao, and installed in cities such as Malaga, Vienna, Bielefeld, Barcelona, etc. The business model is based on savings: if the equipment achieves energy savings in the railway system, then it pays for itself after some time. This innovative product is the first to take advantage of existing technology to harness the energy lost by the train when braking.

INGETEAM, power conversion specialists, has led the INGEBER STANDARD project, with the collaboration of eco-design and LCA consultancy, IK INGENIERIA.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Analyse the environmental optimisation achieved with the product standardisation process (reducing metres of cable and losses in cabling; less movement of people due to simplified equipment commissioning)

- Provide useful environmental information during the production phase to avoid/reduce possible environmental impacts from production, transport or distribution on end customers.

RESULTS

RESULTS

- Environmental analysis comparison using IPPC 2013 methodology (carbon footprint) and RECIPE methodology (environmental footprint) of the non-standard INGEBER product implemented in Madrid metro and standard INGEBER implemented in Barcelona metro.

- More than 50% of the total impact from the non-standard product is 3-phase inductance. The impact is slightly lower on INGEBER standard.

- In the non-standard INGEBER, the INGEBER converter (10%) and the 636A 1.25 mH inductance (7.5%) are also signifi cant. In the case of the standard INGEBER, other components start to become representative of the product’s impact: the control cabinet (13%), the substation cell (11%) and the converter (9%).

- INGEBER STANDARD does not directly reflect an environmental impact improvement of standard INGEBER (122 tonnes of CO2 equivalent emissions compared to 108 tonnes for non-standard INGEBER). However, considering energy savings achieved by INGEBER STANDARD in the use phase, an annual energy saving of 10-15% of current conditions is observed, which reduces the climate change impact from the standard INGEBER model.

CONCLUSIONS

CONCLUSIONS

- INGEBER STANDARD standardisation work has led INGETEAM to create ad-hoc products for each railway case, and to become more agile when it comes to designing and developing modular solutions.

- In the manufacturing phase, more work is required in the final implementation of the product for environmental improvement of the different components which are the highest contributors to the environmental impact. Moreover, in the use phase, comparison work of improvements against the intended function of the product, i.e., energy managed throughout its useful life, must be maintained.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET