ICEBERG, led by the TECNALIA Technology Centre, is a project with 35 participating entities from different European countries. The project implements advances in the circular economy in the construction sector through the development of innovative circular reverse logistics tools and high value secondary raw material production technologies, to gain market confidence and acceptability of recycled building materials at the end of their useful life.

The project aims to design, develop, demonstrate and validate advanced technologies for the production of high purity secondary raw materials (more than 92% in weight) through 6 circular case studies across Europe, covering the circularity of wood, concrete, mixed aggregates, gypsum boards, glass, polymeric insulating foams and inorganic super insulation materials. Three innovative reverse circular logistics solutions are being applied: an intelligent pre-demolition tool assisted by building information modelling (BIM) (with more than 80% accuracy in waste quantification); an innovative digital traceability platform for end-of-life building materials (EBM); and an identification system based on radio frequency and QR codes.

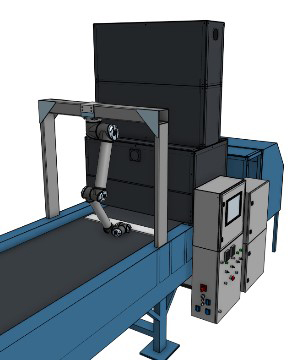

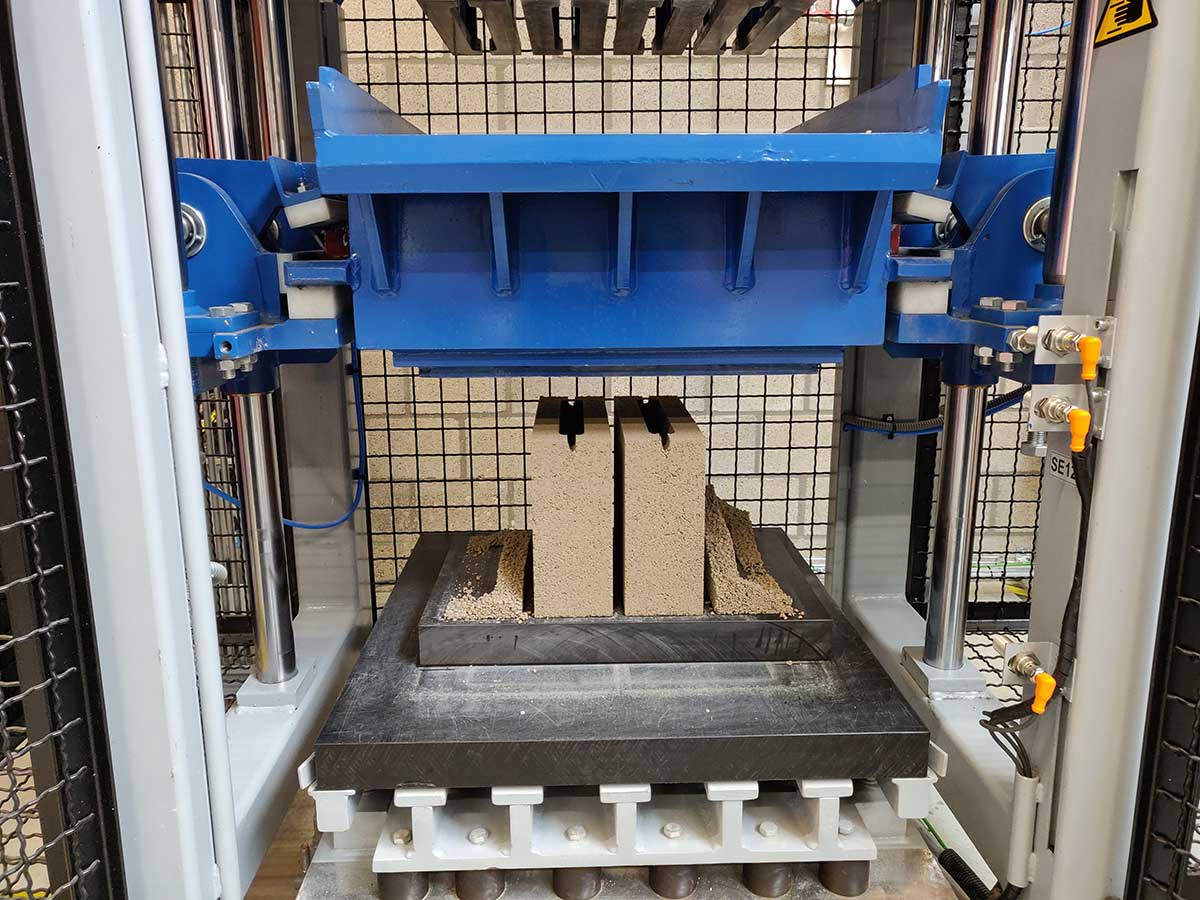

The development of innovative technologies for EBM recovery includes: hyper spectral (HSI) technology, machine learning software and robotic manipulators to increase the efficiency of mixed aggregate sorting; an optimised integrated crushing, sorting and cleaning system and fast pyrolysis and purification processes for wood fractions; mobile thermal attrition unit; hydrocyclone combined with acid sorting and purification to increase the purity of recycled gypsum boards; a combined purification and solvolysis process for polymeric insulating foams; and advanced hydrothermal processing of glass and silica that contain waste.

ICEBERG is a further development of the HISER project. IHOBE's participation has promoted the implementation of ICEBERG case studies in the Basque Country, which are relevant due to their replicability (in this case focusing on circular ceramic products, silica aerogel and polyurethane-based products), as well as implementing the technical developments of the project in technical regulations in the Basque Country, thus contributing to the transfer of the results.

Project website

Project website