REQUIPLAST

CHEMICAL RECYCLING OF PLASTIC WASTE

AROUND 520,000 TONNES OF WASTE WITH A HIGH PLASTICS content and a material value of at least EUR 12.4 million end up in landfill in the Basque Country every year. The main plastic waste streams involved are: plastic rejects from waste electrical and electronic equipment (WEEE) treatment and from packaging sorting plants; end-of-life vehicle (ELV) shredders; paperboard treatment; and mechanical-biological treatment plants (MBT).

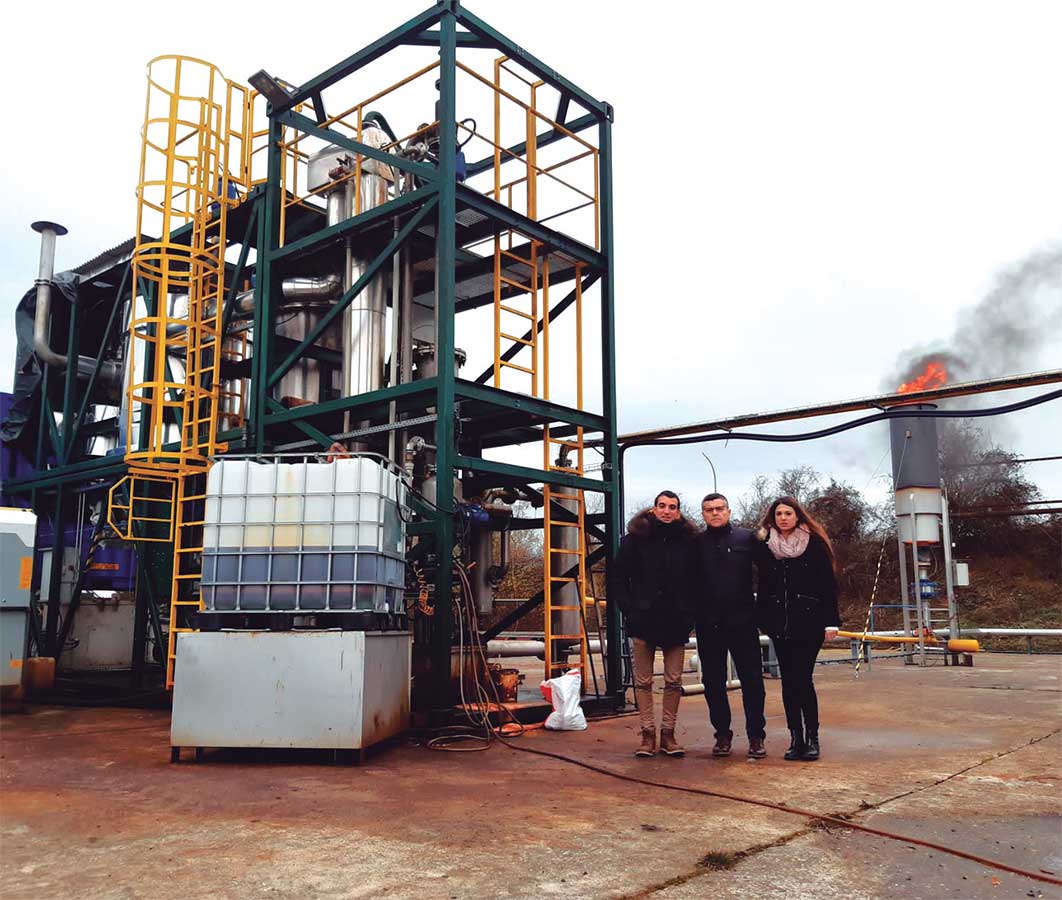

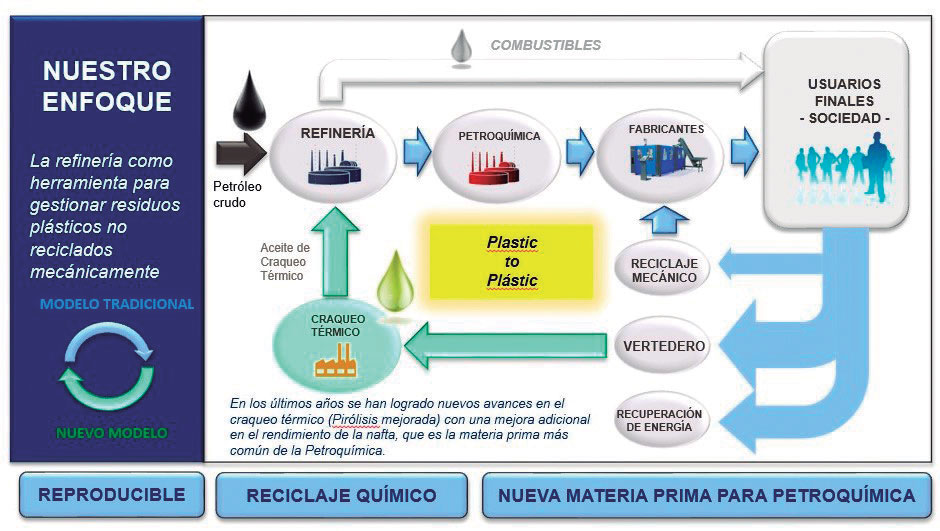

Pyrolysis treatments are very versatile chemical recycling processes for recovery of some waste, but several factors continue to determine their implementation. The downstream oil/gas sector plays a key role in the definitive implementation of improved industrial processes based on these technologies.

PETRONOR leads the REQUIPLAST project with the collaboration of GAIKER Technology Centre.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Demonstrate that pyrolysis is a suitable method with sufficient technological maturity for treatment of plastic waste generated in the Basque Country.

- Obtain an oil stream with a composition tailored to PETRONOR’s requirements for new plastic manufacturing (Plastic2Plastic).

- Effective promotion and boosting the market associated with the use of pyrolysis oils from plastic waste.

RESULTS

RESULTS

- Definition of specifications for pyrolysis oil acceptance as feedstock in the PETRONOR refinery.

- Development of a replicable characterisation methodology for plastic rejects from the Basque Country and waste conditioning processes for their inclusion as raw material in pyrolysis facilities.

- Prioritisation of plastic waste streams susceptible to treatment according to quantity, composition and quality of the oil generated in the Basque Country and yield to oil.

- Activation of a focus group including the main companies generating the waste streams studied in the project.

- Potential annual savings in CO2e emissions amount to 15,000 tonnes per year by treating up to 75 tonnes of plastic waste per day.

CONCLUSIONS

CONCLUSIONS

- REQUIPLAST is essential for PETRONOR, as it replaces the traditional model of waste management and fuel and plastics manufacturing with a new one whereby the refinery becomes a tool for managing plastic waste whose only destination today is landfill.

- PETRONOR has detected a high level of interest in all the organisations involved in the value chain, from waste management to the end-user companies of the products (new plastics and other chemical products), including pyrolysis plant operators and large industrial processing engineering firms.

- The project has a simplified environmental assessment by means of Life Cycle Assessment (LCA), and an economic assessment that has enabled launching an industrial project with investment in plastics pyrolysis in the port of Bilbao.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET