HyperDeepScrap

ADVANCED SORTING OF FERROUS METAL SCRAP WASTE

ARCELOR MITTAL (AM) SESTAO MANUFACTURES HIGH QUALITY FLAT STEEL PRODUCTS from recycled scrap in an electric arc furnace. The main drawback is that scrap contains harmful residual elements such as copper (Cu), tin (Sn), chromium (Cr), nickel (Ni), etc., which cannot be removed in the manufacturing process and must be diluted to guarantee the fi nal quality of the steel to be produced. For this reason, AM Sestao has historically combined a mix of raw materials: 60% - 85% high-quality imported scrap; and 15% - 40% HBI/DRI (hot briquetted iron or direct reduced iron). However, since 2017, AM Sestao is committed to consuming 100% local scrap. In this new context, installing a scrap treatment plant could be of interest to improve the plant’s operational performance.

Currently, the steel industry in the Basque Country has a recycling capacity of 8.3 million tonnes per year, which represents a cost of €2.2 million/year. HyperDeepScrap will enable AM Sestao to become a manufacturer of high-quality flat steel products from scrap metal using Electric Arc Furnace in Europe, and on the other hand, make the AM Basque Country Research Centre a global leader as a R&D and Innovation centre in the development of scrap metal management technologies. TEKNIKER Technology Centre has also participated in the project.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Provide AM Sestao with advanced tools for the characterisation of ferrous scrap that allow it to optimise purchasing strategies for obsolete scrap as main raw material.

- Increase knowledge of existing technologies and capabilities of industrial scrap cleaning processes.

- Analyse in detail the distribution of materials that make up waste from cleaning processes and assess their recovery potential and environmental impact of the recovery processes.

- Develop new technologies for automatic sorting of materials in processed scrap streams under industrial conditions.

- Reduce energy consumption and consumption of ferroalloys and fluxes.

RESULTS

RESULTS

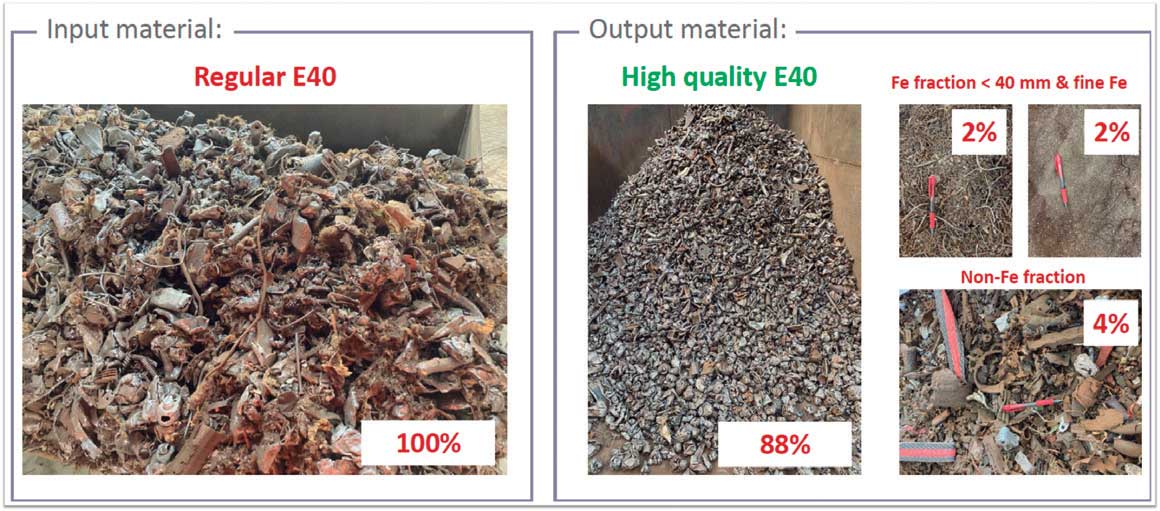

- Improved scrap quality by re-fragmentation of fragmented scrap, with a decrease in non-ferrous and non-metallic materials (Cu reduction by 0.20%; 50% increase in bulk density; and increased Fe content).

- Improvement in most impact categories (between 30% and 50%) assessed by a comparative life cycle analysis (LCA) with and without scrap sorting.

- Development of a pilot sorting facility for ferrous materials capable of detecting percentage in pixels of materials such as Cu, Ni, Zn, Al and sterile materials in acquisitions captured by hyperspectral cameras.

CONCLUSIONS

CONCLUSIONS

- The technical, economic and environmental potential of scrap cleaning techniques is high and given the results obtained, new lines of work have been opened in terms of improving the quality of ferrous scrap.

- The development of a pilot sorting facility for ferrous materials enables the detection of harmful materials, which improves the iron and steel process and also facilitates separated material by the facility to be recovered, reducing the environmental impact they have on electric arc furnace processing, reducing fluxes and waste generated (slag and emissions).

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET