SERVIPCD

PORTABLE DRYER FOR INDUSTRIAL MATERIAL RECOVERY

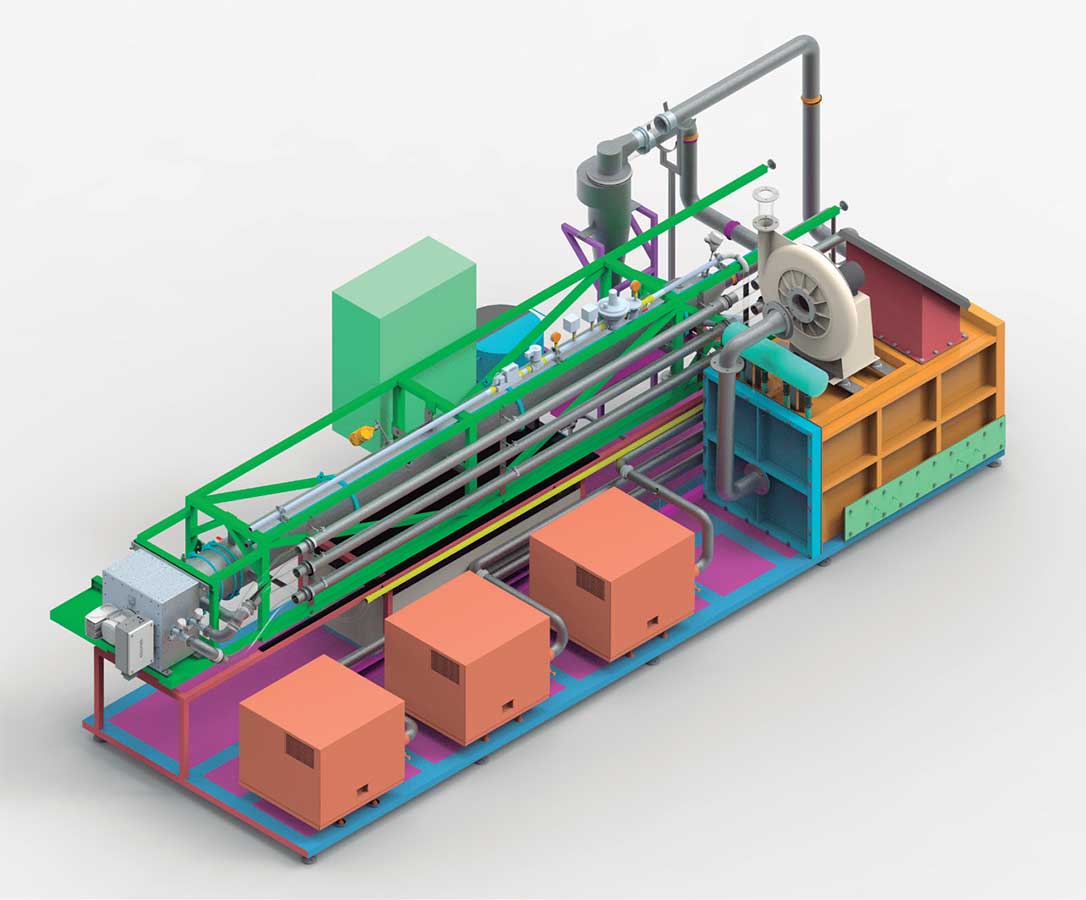

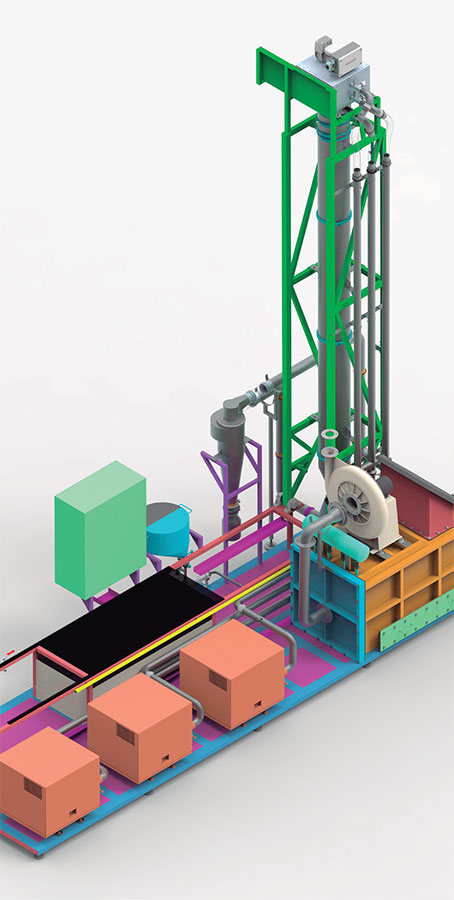

EKONEK HAS DEVELOPED A NEW DRYING TECHNOLOGY THAT ALLOWS TO TRANSFORM LIQUID OR PASTY PRODUCTS into powder instantly, which means converting many waste/by-products into new valuable products. However, when this powdered product is new to the market, on-site pre-commercial manufacturing of the product is necessary to test the market. For this purpose, EKONEK is producing a small, portable version of its drying technology, so that it can be moved to industries for a certain period of time.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Design and build a small and portable 20 kW Pulse Combustion Drying technology dryer, the world’s first reference of its kind.

- Offer a tool to industry for pre-commercial production of useful materials for circular economy applications.

- Demonstrate the operation of the unit in 2 industrial locations.

RESULTS

RESULTS

- Computational fluid dynamics simulations (CFD) to subsequently carry out the mechanical design.

- Expressions of interest from companies to test the equipment with their products, and interest in acquiring this type of small equipment from some technology centres.

CONCLUSIONS

CONCLUSIONS

- Downscaling (making a signifi cantly smaller device than has been done so far) of the technology involved in SERVIPCD is a novel but also complex approach.

- This type of small equipment is in demand, both for rental and for purchase by technology centres for their own development of new powder products.

- The need for key components subject to the supply crisis can lead to delays.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET