ERIC

NEW RANGE OF REFRACTORY ECO-PRODUCTS

Despite the low geographical availability of high purity raw materials for the production of refractory materials, and their associated environmental and economic issues, use of recycled material in their manufacture remains low at 10-15% in the refractory materials sector. Increasing this percentage is a priority for the sector’s entire value chain, due to the scarcity of virgin materials, their high cost, and their production in far-off locations.

ERIC is a project led by KROSAKI, one of the largest producers of refractory products in the world. The TECNALIA Technology Centre has also collaborated in the project.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Reincorporate 50-75% of recovered refractory waste minerals from cement plants.

- Eco-design and develop a new range of refractory eco-products for this purpose.

- Minimise the environmental impact of the final product due to less ore extraction and less transportation.

- Increase productivity in the manufacture of the material by 30%.

- Offer KROSAKI's customer a sustainable product as well as a transferability solution at the end of the life of the waste material in the cement plant, by launching a new eco-product with low environmental impact.

RESULTS

RESULTS

- Inclusion of up to 75% of refractory waste from cement kilns recovered by thermal treatment in the development of new refractory eco-products, with successful characterisation and technical feasibility.

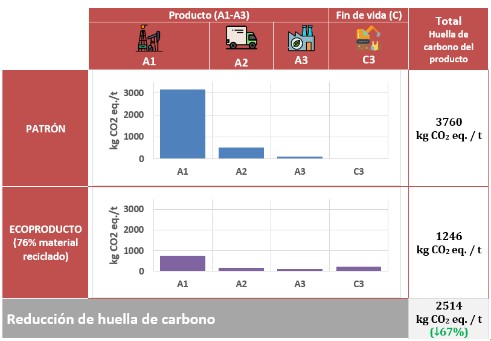

- 67% reduction in the carbon footprint of the production of new refractory eco-products.

- Savings of up to 2.5 tonnes of CO2 equivalent emissions per tonne of new eco-product.

CONCLUSIONS

CONCLUSIONS

- Ecoproducts made from recovered refractory material have the physical-chemical properties required for their reincorporation in certain areas of cement kilns, thus promoting the circular economy of refractory materials.

- Once the first ecoproducts have been successfully obtained from a technical, environmental, economic and commercial perspective, the validation of the products in a cement kiln and their final approval is planned for the near future.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET