CIRTIO2

NEW PROCESS FOR TITANIUM DIOXIDE RECOVERY FROM PAPER MILL WASTE SLUDGE

THE BASQUE COUNTRY GENERATES AROUND 2,000 TONNES OF PAPER SLUDGE with high titanium dioxide (TiO2) content per year, out of the 110,000 tonnes generated globally. Although this sludge is hardly recovered, TiO2 is a relatively high-value mineral that is used as a white pigment. A process to recover TiO2 from waste, which is yet unknown, would save 80% of the energy consumed and CO2 emissions per kg of TiO2 compared to conventional processes for obtaining TiO2 through mining and intensive chemical processing.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Technical and economical characterisation of a new process to obtain TiO2 from TiO2-rich paper mill sludge.

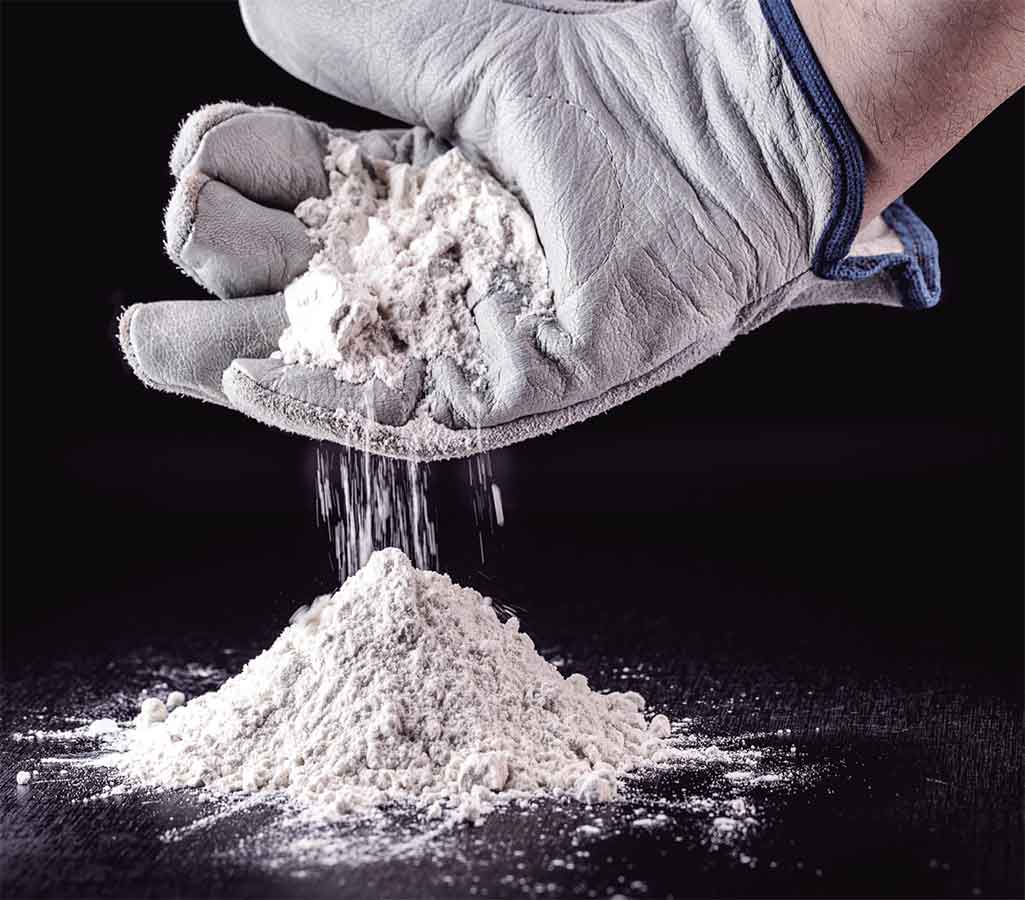

- Obtain a fine powder containing more than 70% TiO2 from paper sludge by means of an optimised TiO2 purification process.

- Confirm that the cost of production is below conventional TiO2 costs.

- Commercial validation of TiO2 obtained by industries that consume it.

RESULTS

RESULTS

- Two final products were obtained in the form of a fine powder containing 70% and 80% TiO2 respectively, from 20-30% TiO2 contents in starting sludge.

- Energy consumption reduction from 100 to 14.72 MJ per kg of TiO2 produced.

- Reduced CO2 emissions from 8 to 1 kg per kg of TiO2 produced.

- Optimised purification process using the Pulse Combustion Drying technology developed by Ekonek, which includes calcination, acid washing and drying.

- Very significant reduction in production costs compared to conventional process of obtaining TiO2 from mining resources.

- Validation of filler applicability, as the products obtained have a whiteness of 94 compared to 100 for pure white pigment.

CONCLUSIONS

CONCLUSIONS

- The industrial process developed is feasible, has an attractive cost and lower environmental impact, plus, TiO2 waste has applications in various industries. However, there are some purchasing barriers since this TiO2 is not exactly the same as current commercially available virgin TiO2, and this it forces the market to reformulate some of its products (which is technically possible).

- The final project implementation requires new potential TiO2 consumers who should be aware of the environmental impact savings derived from the TiO2 produced in the project, as well as exploring further purification of the TiO2 obtained with other industry players.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET