I-CABLE 4.0

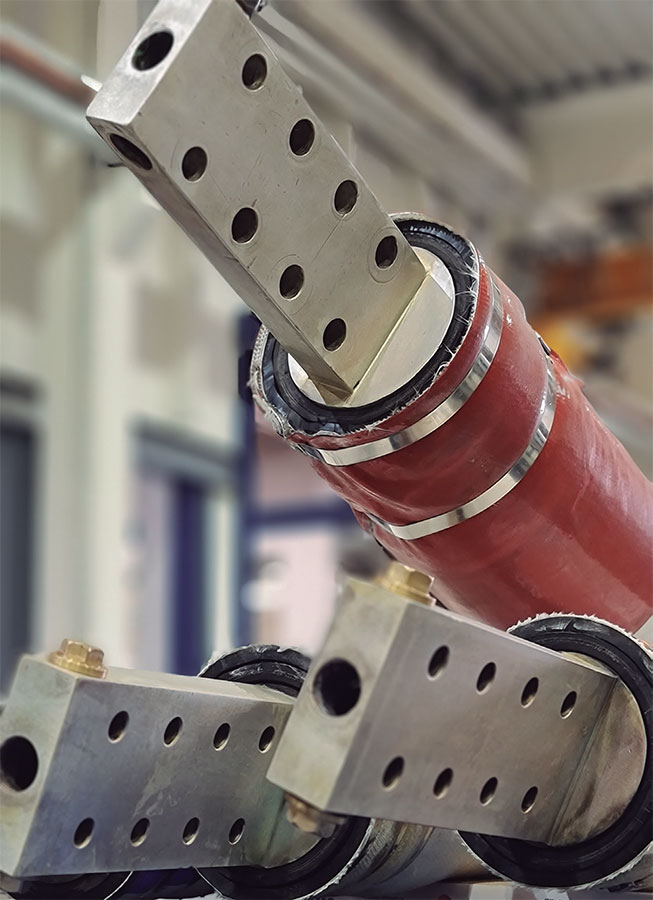

MANUFACTURING SMART CABLES FOR ELECTRIC ARC FURNACES

ELECTRIC ARC FURNACES ARE USED TO PRODUCE CARBON AND ALLOY STEELS mainly by recycling ferrous scrap. In an electric arc furnace, ferrous scrap is melted together with other materials such as ferroalloys to convert the mixture into high-quality steel. Melting of these materials requires the use of high-power electric arcs formed between the electrodes of the furnace, through which a high electric current is passed to form the arc. The heat generated by this arc melts the scrap metal. Maintenance operations on these cables can lead to production stoppages at high costs and with a significant environmental impact on the facilities.

GECSA is a company dedicated to design and manufacture special electrical conductors, automation, Industry 4.0 and industrial processing control, as well as electrical engineering. IK INGENIERÍA, Life Cycle Analysis (LCA) experts, has also been involved in the I-CABLE 4.0 project.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Implement a system for continuous sensing and measurement of the condition of power cables in electric arc melting furnaces.

- Improve process efficiency by means of sensors that allow identifying the condition of cables in a preventive manner.

- Extend the service life of cables.

- Increase reliability.

- Reduce the use of materials and resources used in maintenance.

RESULTS

RESULTS

- Reduced environmental impact on climate change by 23%.

- Reduced environmental impact on ozone layer destruction by 38%.

- Reduced environmental impact of fossil fuel consumption by 37%.

CONCLUSIONS

CONCLUSIONS

- Capturing high intensity signals must be conducted using galvanically isolated cabinets and high-power connectors.

- Once the project results are validated, GECSA will carry out actions to disseminate and communicate the new technology to current and potentia corporate clients.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET