HPP

HIGH PURITY SECONDARY ALUMINIUM OXIDE FOR LED AND ELECTRONIC COMPONENT MANUFACTURING

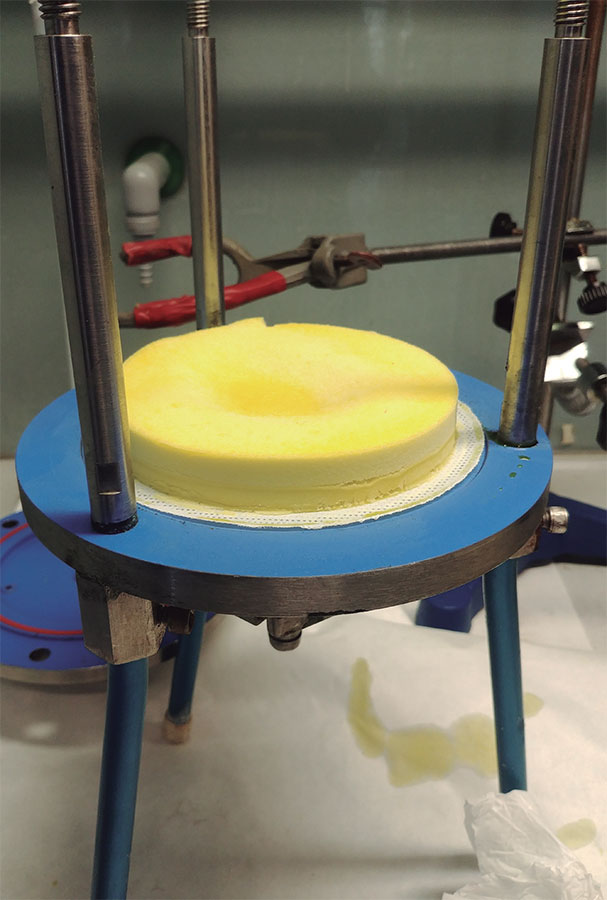

HIGH PURITY ALUMINA (HPA) IS A HIGHLY DEMANDED PRODUCT OF HIGH ECONOMIC VALUE AND CRITICAL TO MANUFACTURE SYNTHETIC SAPPHIRE, which is widely used in the manufacture of electrical and electronic components. Typical HPA production is linked to very expensive raw materials with high energy costs and subject to environmental policies. Secondary aluminium oxide is a source of alumina with impurities and a potential alternative raw material to produce HPA. Since quality requirements are very demanding, the chief technological challenge is to maximise aluminium oxide purity.

BEFESA, a leading European company in hazardous waste recycling services for the aluminium industry, has worked in different lines to recover secondary aluminium oxide as an alternative raw material to bauxite.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Obtain an alternative material of the so-called 4N grade with the appropriate characteristics and properties of high purity alumina, and valid for the manufacture of LEDs and electronic components.

- Reduce the amount of primary aluminium processed and the extraction of bauxite ore to 10,000 tonnes per year at European level.

- Use a non energy-intensive secondary source material without extraction of natural resources or import of materials.

- Reduce the cost of obtaining the product by 7%.

- Diversify into new applications and higher valueadded sectors with competitive solutions.

RESULTS

RESULTS

- A high purity alumina was obtained from secondary aluminium oxide, but did not reach grade 4N, with a tolerance limit below 100 ppm.

- The chemical intermediate obtained, aluminium chloride grade at 18% Al2O3, can be used as a potential alternative to the coagulant market in the paper and/or water treatment industries, and thus, become a new product of recycled origin.

CONCLUSIONS

CONCLUSIONS

- HPP involved a very high technical risk due to the high purity (99.99%) required by a 4N-grade HPA. The high degree of purity achieved (82.0%) is not sufficient to demonstrate the project viability. Although this a very ambitious challenge, the line of research is expected to continue, optimising parameters and facilitating selective recovery by means of a new R&D and Innovation project with a public-private partnership in collaboration with the Bilbao School of Engineering (UPV/EHU).

- The results obtained have given rise to a new market for secondary aluminium oxide as a raw material to produce aluminium chloride (chemical intermediate obtained after chemical treatments), used as a coagulant in the paper and water treatment industries. The technical, economic and environmental feasibility of this potential new product will be analysed in the short term.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET