ALRE

HIGH-PERFORMANCE REFRACTORY ELEMENTS MADE FROM RECOVERED MATERIAL

THE RISING PRICE OF REFRACTORY RAW MATERIALS and China’s dependence on bauxite and very high aluminium oxide (Al2O3) raw materials has encouraged European refractory producers to look elsewhere for new synthetic and recovery alternatives. DEGUISA designs, manufactures, installs and commissions refractory linings for furnaces.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Reduce dependence on natural resources in the manufacture of refractory materials in furnaces.

- Recycling refractory raw materials.

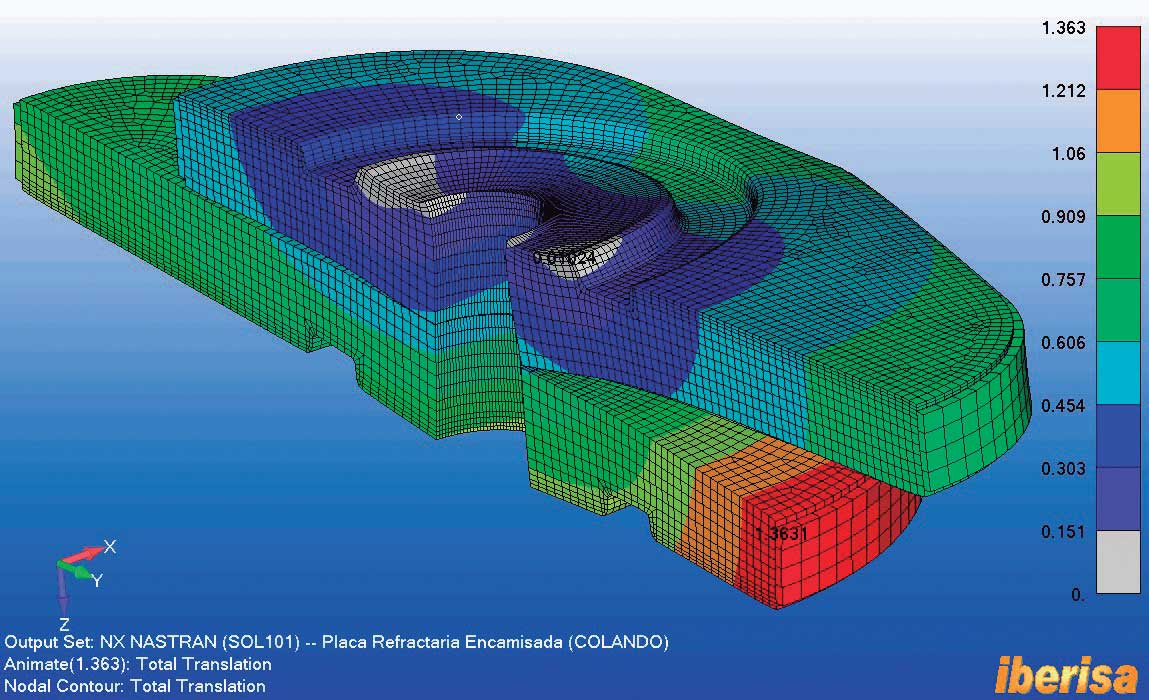

- Reuse refractory slide valve parts and achieve the same performance in use as new parts.

- Design new, more appropriate geometries in wear and corrosion areas of refractory parts.

- Reduce energy consumption.

RESULTS

RESULTS

- Registration of 5 new designs of iron ladles and ditches that have been commercially exploited.

- 7 new prototypes of ladles, partitions and gutters.

- Viable recovery and reuse of high-performance refractory materials, adequately processed and designed, in steelworks slide valve systems and cast-iron ladles.

- Reused high added value Al2O3·ZrO2·C refractory materials in slide valve plates and applied in steel ladles.

- Development of structural designs that prevent premature refractory wear.

- Integration of a refractory waste selection and recovery process applied in the manufacturing process of formed and unformed refractory materials.

CONCLUSIONS

CONCLUSIONS

- ALRE has been able to expand, maintain and distribute DEGUISA’s insight and external knowledge of technical recovery processes.

- Working closely with client companies such as FAGOR and ARCELOR, which have collaborated in the recovery and use of the refractory materials used in ALRE, has contributed to overcoming the entry barrier into the recycled refractory product market in the sector.

- Given that it is possible to recover and reuse high-performance refractory materials in steelworks slide valve systems and cast iron ladles, specialised refractory recovery plants can be proposed, taking advantage of synergies with existing recovery plants, and carrying out a project on refractory waste from aluminium industry salts.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET