ECOPUMP

ECO-DESIGN OF A NEW CENTRIFUGAL PUMP

IT IS ESTIMATED THAT APPROXIMATELY 11% (300 TWH) OF THE ANNUAL ELECTRICITY CONSUMPTION in the EU-27 is linked to centrifugal pumps, a major environmental impact that according to preliminary Life Cycle Assessments (LCA) happens mainly in the use phase, where energy efficiency is a key parameter.

EMICA is a company dedicated to the manufacture and marketing of centrifugal pumps, which has its own patents and in-house maintenance and service workshops.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Improve a successful centrifugal pump model selected from the EMICA catalogue, to develop a simplified and industrialisable method and apply the improvements to the rest of the EMICA catalogue.

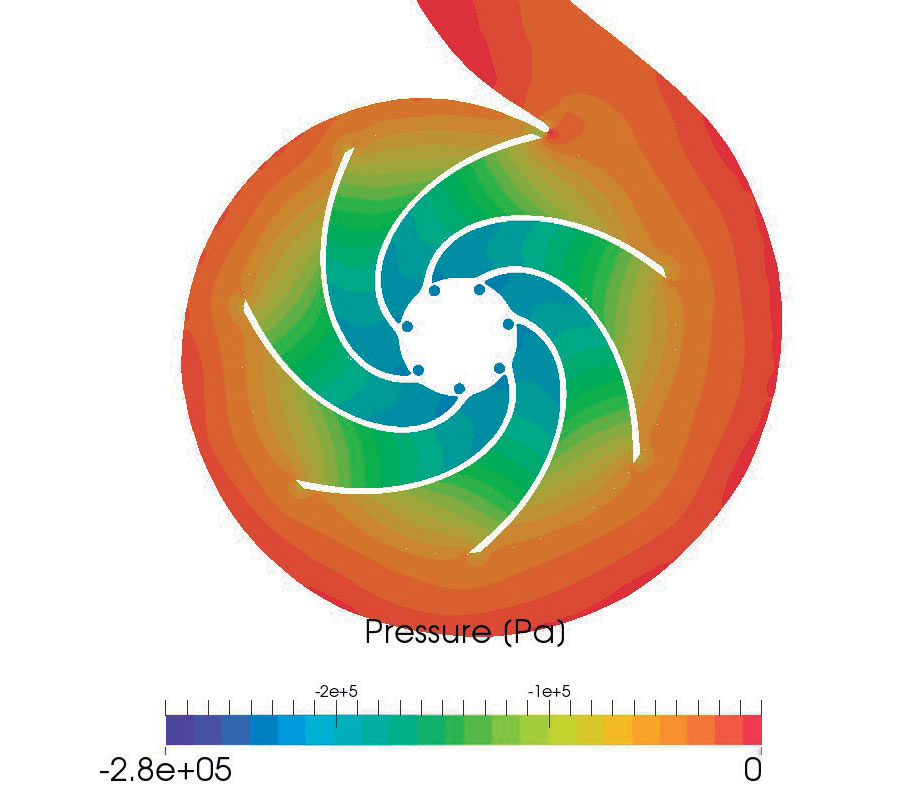

- Validate a CFD (computational fluid dynamics) model and implement an improvement system to be replicated in several models.

- Improve performance in the selected pump at optimum point - a 5% improvement would reduce the annual CO2 equivalent emissions per pump unit tested to 37 tonnes, and would cut current emissions by 10% at same hours of use per year.

RESULTS

RESULTS

- The physical prototype manufactured was tested on a test bench to verify the CFD model, which showed that the parts with the greatest impact on the equipment hydraulic performance were the impeller, the drive body and the suction cover.

- Failure to improve pump performance through various interactions with a series of redesigns, which failed to achieve substantial improvement.

- Modification of elements as recommended by a new pump design software, which did not substantially improve performance at the optimum point.

CONCLUSIONS

CONCLUSIONS

- ECOPUMP showed that the performance of the pump analysed, and probably of many pumps in the EMICA catalogue, reached asymptote in terms of basic design improvement, probably derived from the company’s extended background and matured hydraulic knowledge.

- It seems necessary to readjust the lines of work towards an improved wider system - the motor- pump system - and to optimise its actual consumption, as this system is made up of two elements with different points of optimum efficiency the motor and the pump.

- The operational needs of the client company may vary from one day to the next, and in many cases the work points of the actual system may need to be shifted from those that are theoretically designed.

- In order to analyse motor-pump systems from a real consumption improvement perspective of the assembly at the actual points (fixed or variable) of operation of the client company, competitive driving and control systems must be developed.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET