REGENERA

DEVULCANISATION OF WASTE RUBBER TO BE RETURNED TO LIFE CYCLE

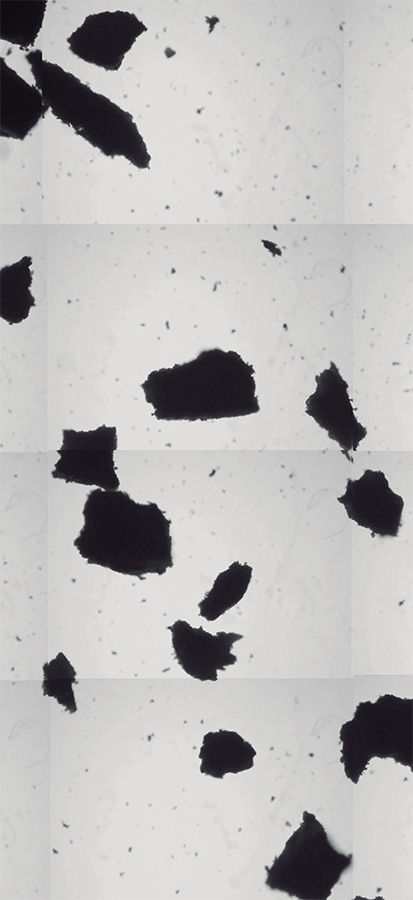

UNTIL NOW, THE BEST WAY TO COMPLY WITH WASTE HIERARCHY AND AVOID sending by-products of rubber manufacturing to landfill has been to grind them into particle sizes of less than 10 millimetres so that they can be reused to manufacture rubber products. Then, these finely ground granules are mixed with virgin rubber in a percentage permitted by the product quality. Today, new technologies making it possible to achieve something akin to a reversal vulcanisation of rubber, i.e., the reason for its traditional non-recyclability, have begun to emerge. These technologies, called “regeneration”, basically consist of controlled breaking of sulphur (S) bonds without excessively affecting the necessary carbon (C) bonds. CIKAUTXO, developer of REGENERA, is a leading company in the innovation of rubber and plastic products.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Identify and assess available devulcanisation technologies by obtaining pilot samples of the waste rubber treatment result with these technologies.

- Obtain offi cial approval of secondary raw materials obtained in order to introduce them in applications other than the automotive and domestic appliance sectors, such as, for example, playground floors or athletics tracks, etc., with subsequent reductions in environmental impact and economic savings.

RESULTS

RESULTS

- Identification of different devulcanisation technologies.

- Testing of the technologies identified, subjecting raw materials obtained to compatibility tests with CIKAUTXO specifications in its different product lines; discarding those technologies that are not suitable and carrying out approval processes with the most compatible technologies.

- An economic assessment of the viable alternatives and drawing conclusions to design an implementation plan over time.

CONCLUSIONS

CONCLUSIONS

- This technology is at an increasing TRL level and although it lacks the quality standards typical of mature sectors, and the supplier companies identified are also emerging and without structured supply, applications are gradually appearing.

- Economic costs related to transformation would only be profitable in a scenario of rising raw material prices, which is currently the case, and this will allow the project to be developed.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET