INERGAZKI

CONTINUOUS PARTICLE SEPARATION FOR EDM MACHINES

EDM is a non-contact material removal process using electrical discharges in a dielectric medium between the part and an electrode. The dielectric fluid cools the work area, contains the metal particles generated in the starting process, and must have a low content of these particles to maintain process efficiency, repeatability and quality of results. For this purpose, two types of filters are used in wire EDM (WEDM), which uses deionised water as a dielectric: those based on cartridges with paper filters and self-cleaning filters (mineral filter based on granules of different calibre) of which ONA is the only manufacturer. Today's new machine requirements in the premium sector (ONA AV series) require a higher separation capacity, which has been achieved by means of an additional stage based on conventional disposable cartridges. This solution, although feasible as it increases the lifetime of the disposable filters, requires management of the filter elements after they have been exhausted. The higher plant occupancy of the self-cleaning filters is also a customer concern.

ONA ELECTROEROSION is the world's most specialised manufacturer of EDM machines. INERGAZKI is being developed with the support of the AZTERLAN Technology Centre.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Eco-design a new, continuous, ecological filtering system based on the principle of separation by inertial forces that guarantees filtration down to 2 microns for any type of particle and material, comparable to disposable paper cartridge filters.

- Minimise the space occupied by the machinery of the new filtering system at the plant.

RESULTS

RESULTS

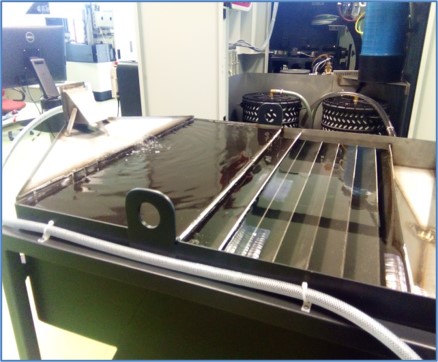

- Design and manufacture of a full-scale prototype to be coupled to an ONA Premium series machine, with a separation system by centrifugal forces and a decanter with lamella.

- Consideration of flocculant and cartridge filter consumption and waste generation during the use phase, as well as material and energy consumption and emissions during the manufacture of filter systems, as aspects with the highest environmental impact and therefore a priority.

- Increased filtration quality compared to the mineral filter and prolongation of the service life of the paper cartridges or even the possibility of doing without them.

- The much more compact design of the new filter system improves the critical aspect of industrial plant occupancy.

CONCLUSIONS

CONCLUSIONS

- The new filtration system has two distinct phases: the first is based on the separation of particles from the WEDM process using centrifugal forces, and the second focuses on a settling system with a geometry based on lamella to favour settling, in a continuous process without self-cleaning or stoppages.

- INERGAZKI's next steps include carrying out industrial tests under conditions not addressed in the project and overcoming the technical problems to be expected in an initial prototype, which have not yet made it possible to visualise industrialisation, although feasibility has been demonstrated under laboratory conditions

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET