NUCAAS

CEMENT PRODUCED FROM LOCAL INDUSTRIAL BY-PRODUCTS

THE ENVIRONMENTAL IMPACT OF PORTLAND CEMENT INTENSIVE USE IN THE CONSTRUCTION SECTOR demands new mineral supplements with hydraulic and pozzolanic potential. Over 1 million tonnes of Construction and Demolition Waste (CDW) are generated in the Basque Country alone (20% by weight of the total waste generated). This is a strategic waste stream for the Basque Country as it contains mineral resources with a high potential for use in binary cement formulation.

NUCAAS is a project led by CEMENTOS LEMONA, a cement manufacturer which has involved the entire value chain: white slag supply companies such as the steel manufacturer SIDENOR ACEROS ESPECIALES; construction waste management companies such as HIERROS Y METALES GUTRAM; and construction material application companies such as EXCAVACIONES Y OBRAS DE DIEGO S.L.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Obtain available waste that meet the appropriate requirements to serve as raw materials for Portland cement.

- Achieve concrete formulated with new cements offering adequate performance for use.

- Obtain cost-competitive waste compared to that available on the market and considering the processes to be carried out.

- Reduce the environmental impact of new cements in a complete positive way compared to conventionalcement.

- Integrate the value chain made up of producers and waste management companies, cement manufacturers and users of cement in construction products, applying the principles of circular economy.

RESULTS

RESULTS

- CDW collection and conditioning in a recycling plant to be introduced into cement.

- Manufacture of two binary cements under real conditions using cement plant resources including: recycled concrete whereby hydrated cement component is able to promote the formation of new CSH gel by seed effect; and recycled ceramic as a brick whose richness in amorphous silica gives it a pozzolanic capacity which is useful for cement setting.

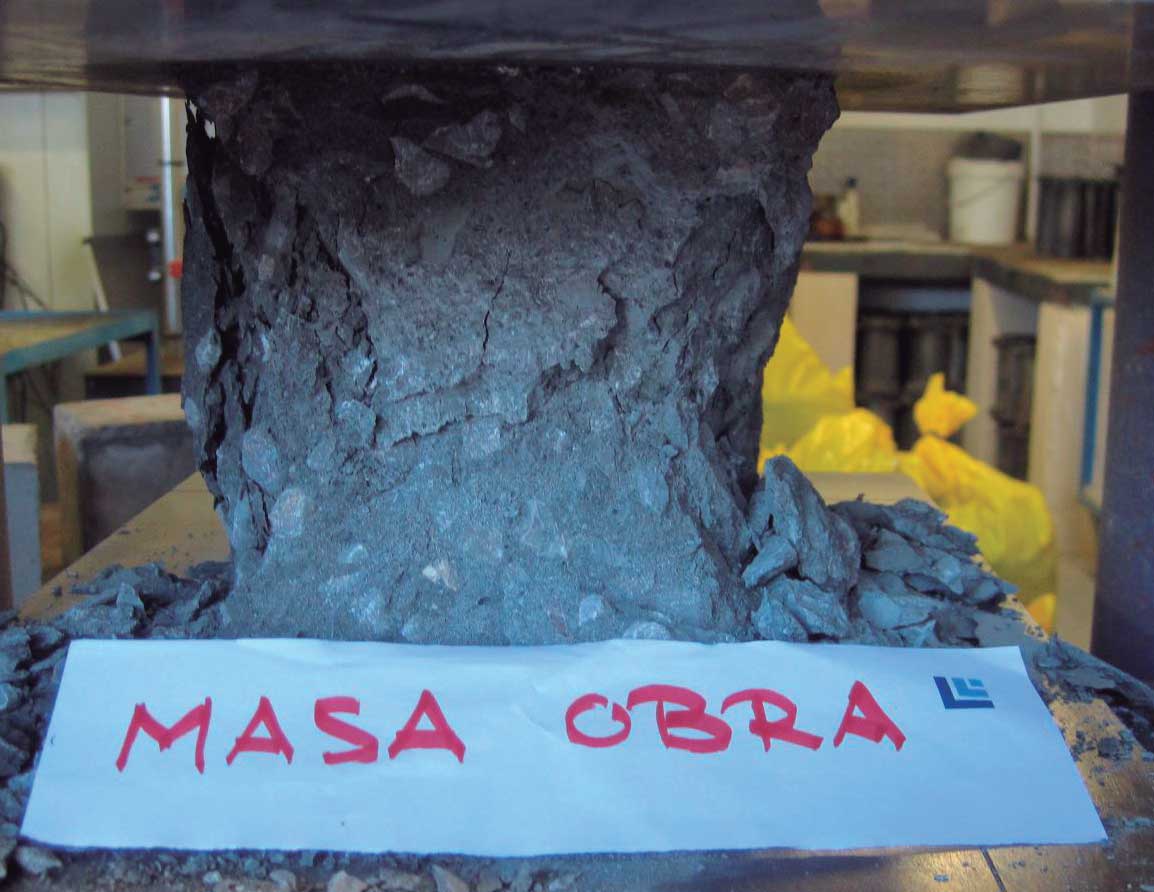

- Use of new binary cements by end users for incorporation into concrete formulations. Both binary cements achieve the same mechanical performance as their conventional cement counterparts.

- Practical on-site application of concrete with one of the new binary cements, with similar performance to that of concrete with commercial cement.

- Potential savings of 2,300 tonnes of CO2 equivalent per year.

CONCLUSIONS

CONCLUSIONS

- NUCAAS opens a new potential market for CDW as an addition to cement provided that cement standards permit the addition of conditioned CDW as up to 10% to cement, and that cement manufacturers can pass on the price increase resulting from the use of recycled concrete CDW, whose processing and transport costs for use in cement manufacture make it more expensive than current non-renewable natural raw materials.

- This opens the door to new business opportunities for both waste management companies and cement companies. Waste management companies can expand their waste recovery market, while in turn reducing the waste volume going to landfill. Cement companies can find alternative raw materials to natural raw materials.

- The scope of application of these results is currently being analysed in order to introduce the CDW market in the Basque Country, as a supplier of a solid product capable of satisfying local demand while maintaining the necessary quality standards.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET