ProTIER

INTRODUCING CIRCULAR ECONOMY PROTOCOLS IN A TIER 1 AUTOMOTIVE COMPANY

AURIA IS A TIER 1 AUTOMOTIVE COMPONENTS COMPANY (direct supplier to car manufacturing companies). It manufactures floors (front and rear) and side panels for vehicles from several layers of different plastics, which are diffi cult to separate from each other and therefore to recycle. However, in the manufacturing process of both, large offcuts are discarded and due to the lack of adequate recycling processes end up in landfi ll. Under standard production conditions, discarded offcuts can amount to 3,000 tonnes per year. In ProTIER, AURIA relied on the GAIKER Technology Centre and the circular economy specialist company ZICLA.

OBJECTIVES

OBJECTIVES

- Exploit and optimise material resources in the production of flooring and acoustic and thermal insulation for the automotive industry.

- Recycle up to 1,500 tonnes per year of waste currently sent to landfill.

- Use recycled raw materials in new products, with at least 15% concentration; and reduce the corresponding consumption of virgin raw materials.

- Introduce secondary raw materials in other sectors.

RESULTS

RESULTS

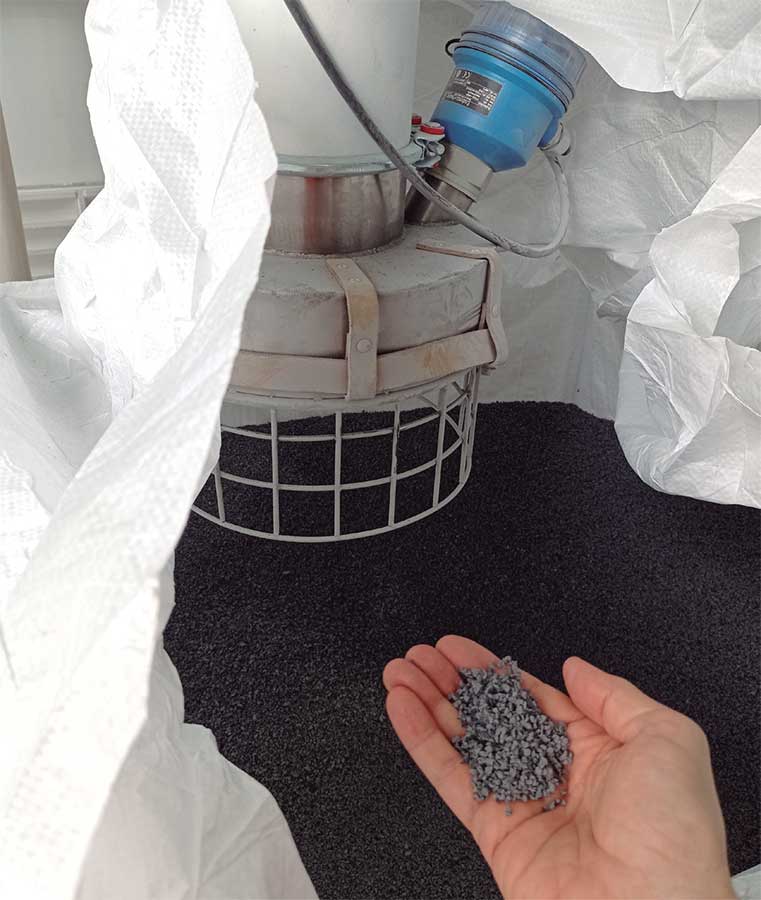

- Optimisation of shredding and separation processes of plastic materials from AURIA soil trimmings.

- Procurement of approved recycled material for own production.

- Industrial implementation of a process capable of handling up to 1,800 tonnes of material per year.

- Manufacture and validation in production of new boards with 15% of the recycled material obtained.

- Reduction of 700 tonnes of virgin raw material per year.

- The new process achieved a reduction of 3,400 tonnes of CO2 equivalent per year.

CONCLUSIONS

CONCLUSIONS

- ProTIER has implemented in AURIA an industrial process for the treatment and separation of plastics that form floor layers of the cars it manufactures; and has recovered the most interesting material from them to incorporate it again in its new products.

- This implementation was achieved thanks to the characterisation of the materials and optimisation of the production parameters in the pilot plant for study and treatment of plastics at GAIKER, and to the samples obtained on an industrial scale at the plant. In addition, there is a surplus of secondary raw materials which is undergoing approval processes on other markets.

- The process has been technically demonstrated and its industrial implementation has been achieved.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET