RECITEST

HIGH-VALUE TUBE PACKAGING RECYCLING SOLUTIONS

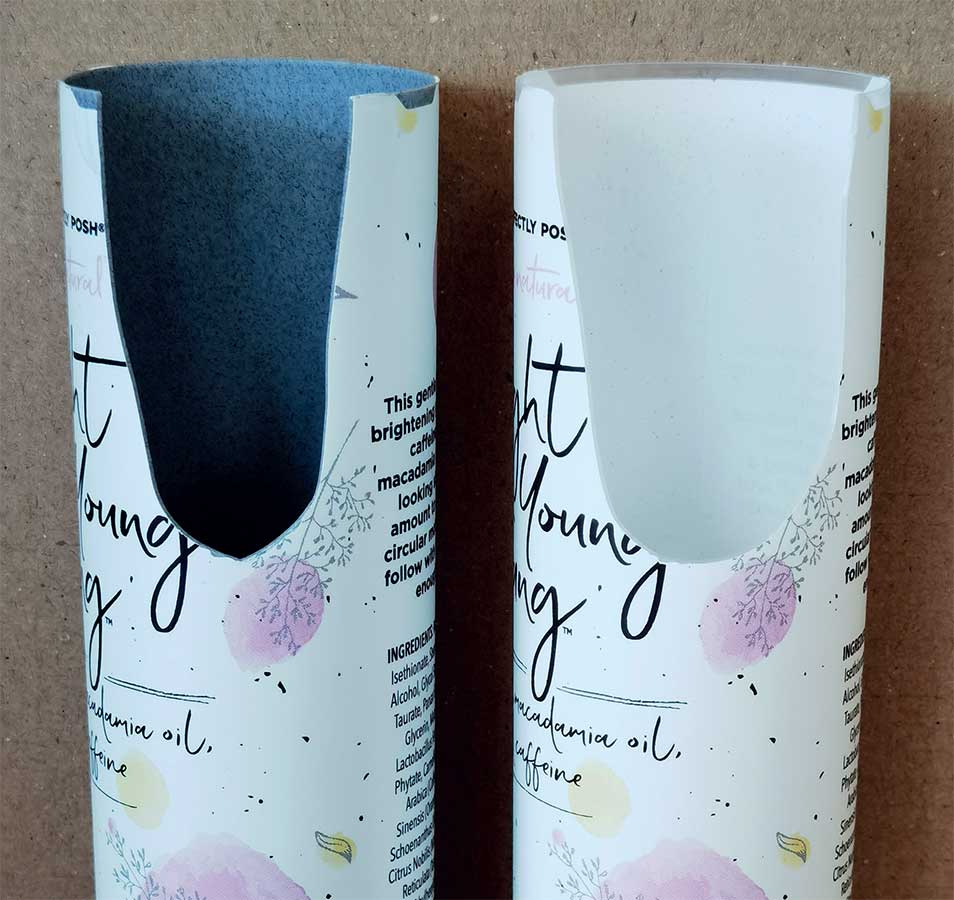

THE USE OF RECYCLED MATERIALS IN THE PLASTIC PACKAGING SECTOR is something the sector is integrating as an unavoidable issue in the development of new projects, both as a legal obligation and as an immediate market demand. CTLpack, the leader in highquality tube packaging solutions, is committed to implementing the principles of the new circular economy and contributing to develop more sustainable products. The possibility of reusing materials destined to become waste is an innovation and adds signifi cant value in the field of sustainability in such a demanding sector.

In RECITEST, CTLpack has collaborated with AIMPLAS Technology Centre.

DRIVING FACTOR

OBJECTIVES

OBJECTIVES

- Recover swarf (industrial waste) directly from the machine, once appropriately treated and introduce them into ESTube manufacturing process or other applications, in a percentage to be determined.

- Research and implement a process including compaction, external grinding and external regeneration of the polymer by a process that allows the removal of inks and other decorative elements.

RESULTS

RESULTS

- Swarf produced in the plant can be regenerated and processed in the available means of production, even at high utilisation rates.

- The material is not suitable to be used in applications requiring food contact, since the removal of remaining inks and varnishes has not been possible, and this has added colouring to the regenerated chippings, making organoleptic properties not optimal and compromising its suitability for food contact.

CONCLUSIONS

CONCLUSIONS

- The resistance of packaging decoration, especially in the cosmetics sector, is characterised by its highquality standards in terms of decorative richness (effects and colour density), bonding to various substrates, resistance to chemical attack such as solvents, water, etc. Sometimes, this makes decoration practically indestructible, which obviously makes it difficult to remove.

- The next steps will focus on assessing and optimising waste washing processes to remove decoration, which would open up a range of options to achieve the optimal objectives of this project. In parallel, realistic options facilitating the removal of decoration, or even avoiding it where it is not necessary, will be analysed.

ENVIRONMENTAL

TECHNICAL

ECONOMIC

COMMERCIAL

ON THE MARKET